Vibration absorber for drive shaft

A transmission shaft and vibration absorber technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, rotation vibration suppression, etc., can solve the problems of high production cost, mismatch of vibration frequency, and impact on automobiles, and achieve low cost and easy processing , ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The transmission shaft vibration absorber according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

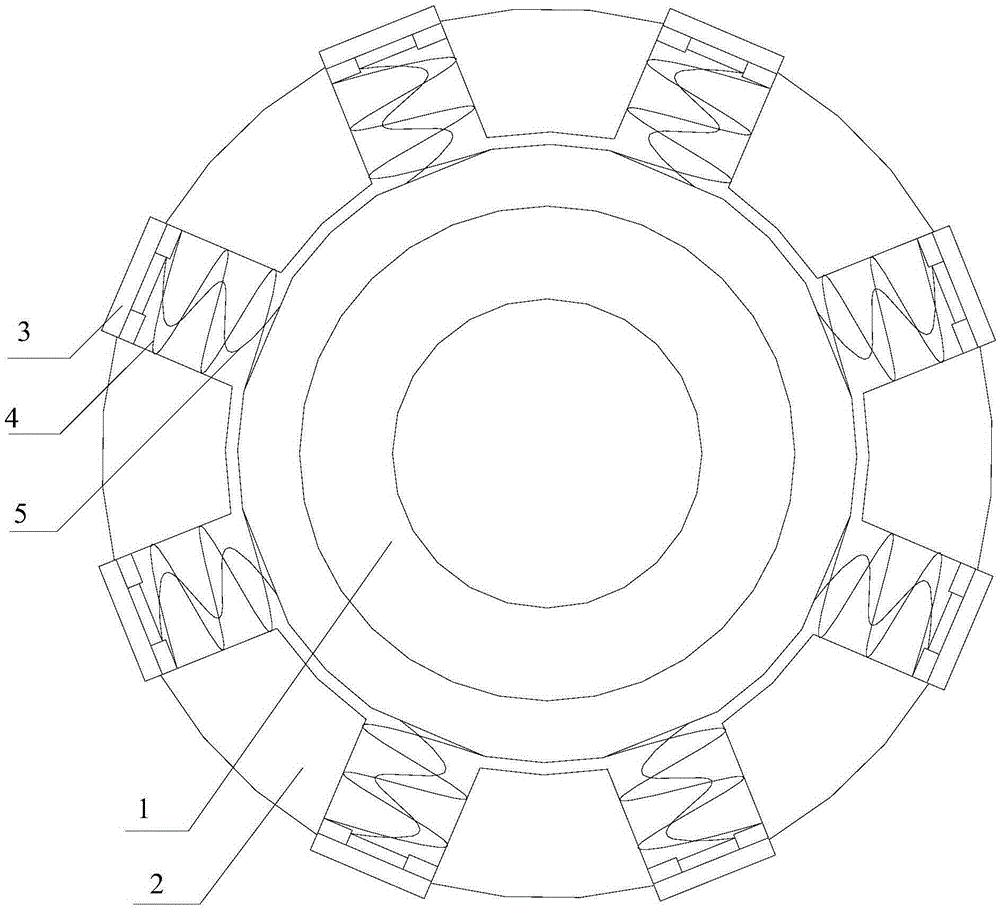

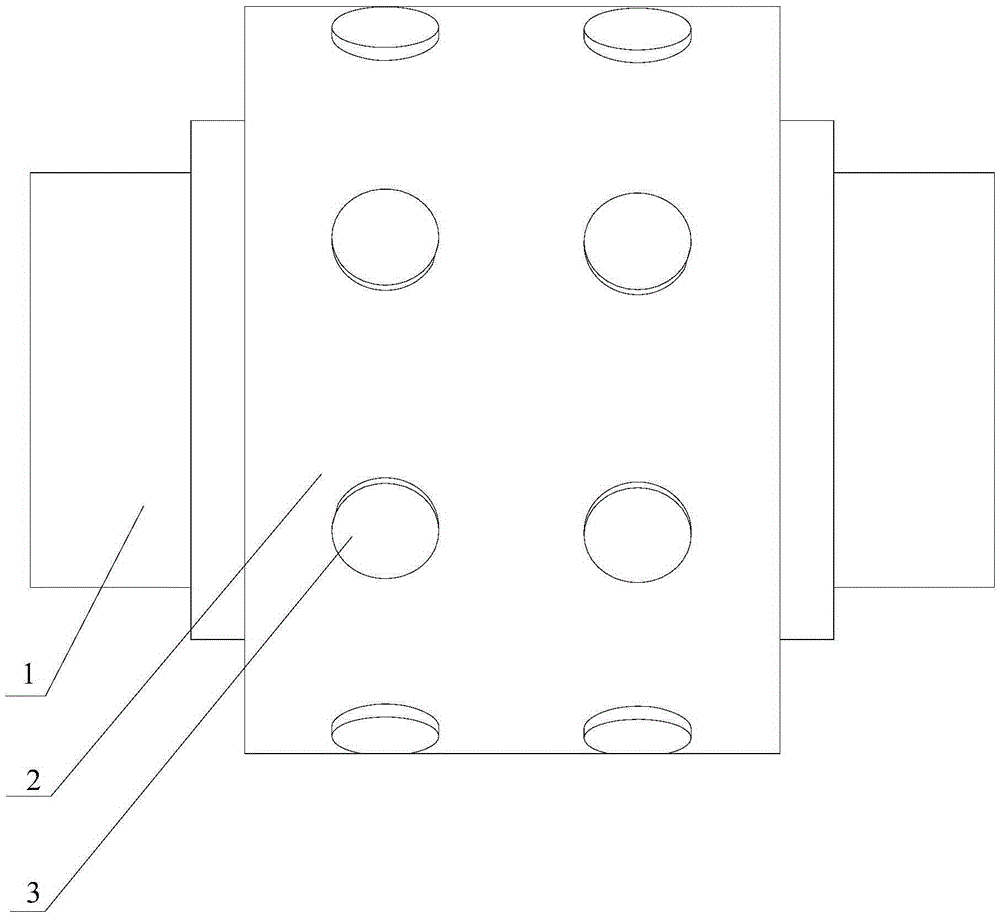

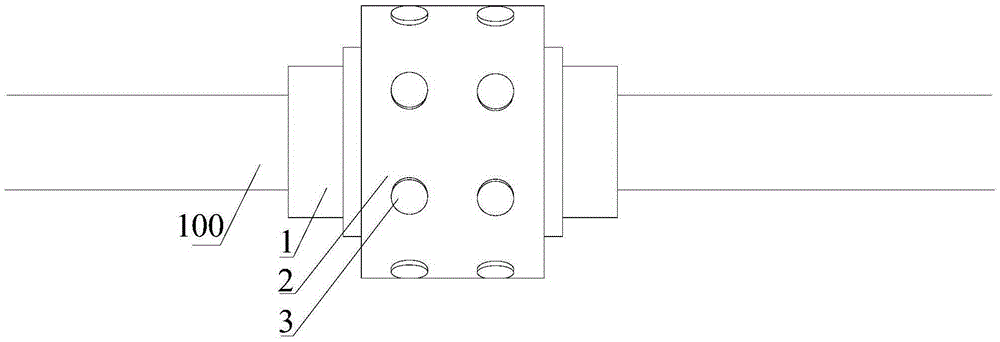

[0019] Such as figure 1 , figure 2 and image 3 As shown, the transmission shaft vibration absorber provided by the embodiment of the present invention includes a ring-shaped rubber block 1 and a mass block 2 arranged outside the ring-shaped rubber block 1, and a plurality of through holes are distributed along the circumferential direction of the mass block 2, and the through holes An adjusting bolt 3 is screwed in, and a spring is also arranged between the adjusting bolt 3 and the rubber block 1, and one end of the spring abuts against the annular rubber block 1, and the other end abuts against the adjusting bolt 3. image 3 A schematic diagram of installation of the transmission shaft vibration absorber on the transmission shaft 100 is shown.

[0020] As we all know, the vibration frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com