Rice precision hole sowing device

A precise, hole-seeding technology, used in hole-seeding planters, sowing, and planter parts, etc., can solve the problems of falling on the ground, seed damage, and high seed injury rate, reducing seed injury rate, improving hole formation, The effect of high hole pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

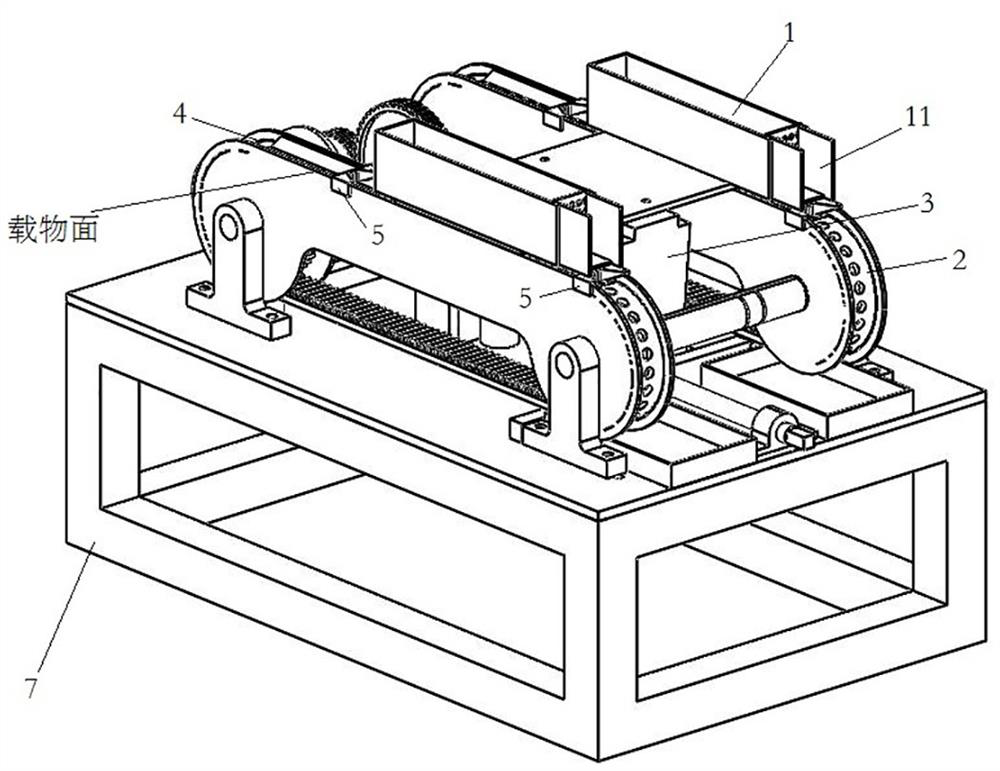

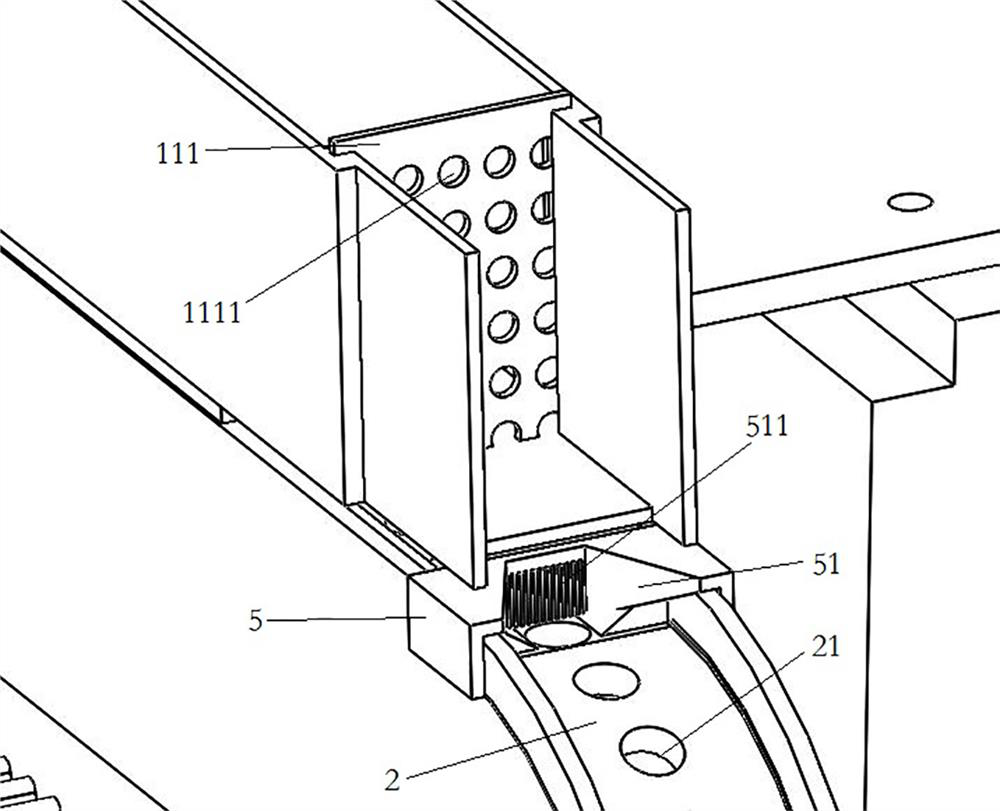

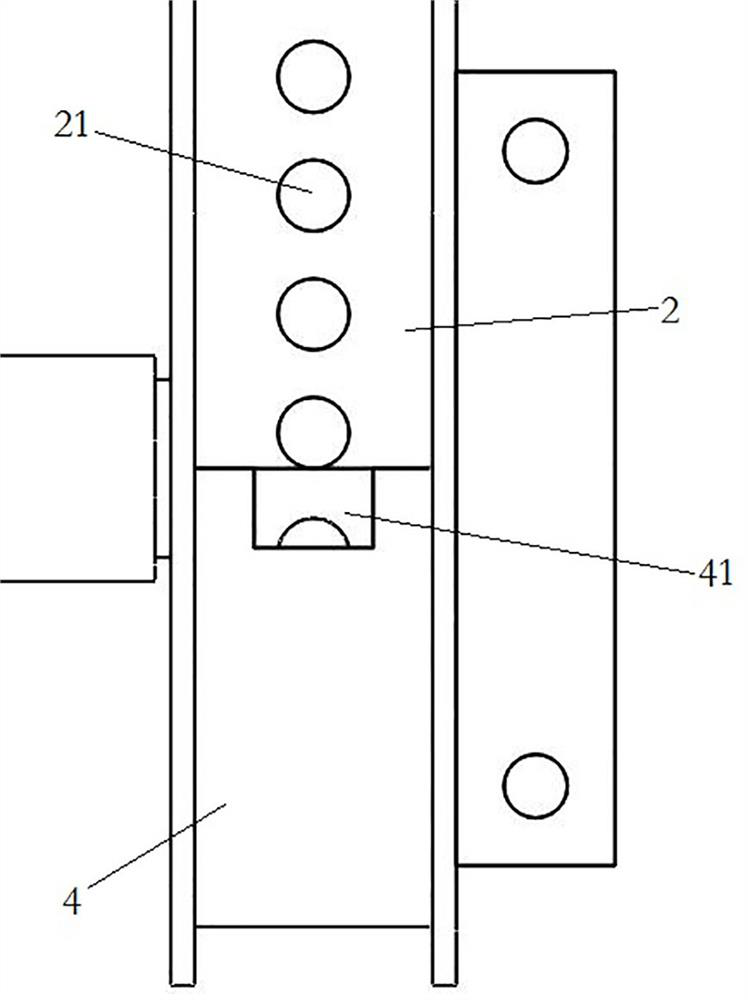

[0032] A precise hole seeding transposition, comprising: a seed trough 1, a conveyor belt 2, a vibrator 3, and a shielding plate 4. The conveyor belt 2 is in the shape of a closed loop. A plurality of grooves 21 for carrying seeds are uniformly arranged on the conveyor belt 2 . The conveyor belt 2 is connected to the power device in transmission, so that the conveyor belt 2 can drive the groove 21 to move periodically.

[0033] The seed tank 1 is used to carry seeds. The seed trough is arranged on the side corresponding to the loading surface of the conveyor belt. The seed trough 1 is connected to the vibrator 3 through transmission, so that the vibrator 3 can drive the seed trough 1 to vibrate synchronously when vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com