Underground hydraulic piston pump

A hydraulic piston and double piston technology, applied in pumps, liquid displacement machinery, pumps with flexible working elements, etc., can solve problems such as reducing pump efficiency, increasing processing equipment and processing costs, and grinding production strings, etc. Achieve the effects of reducing production costs, increasing ultimate recovery, and increasing pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

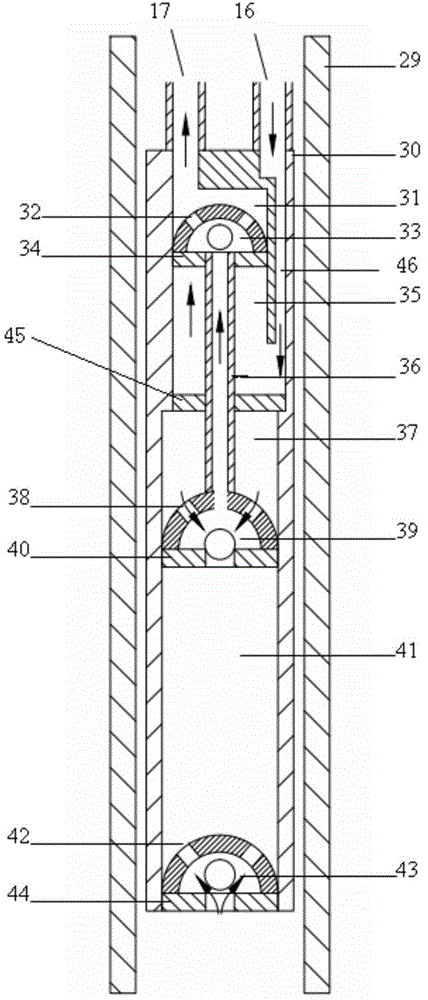

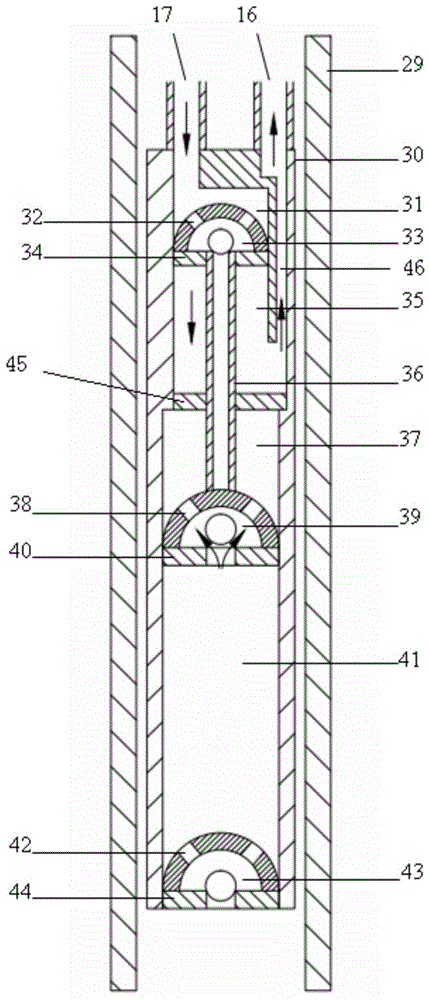

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] figure 1 and figure 2 It shows the downhole hydraulic piston pump of the present invention. When in use, the downhole hydraulic piston pump is lowered into the environment control in the downhole casing by using the flexible tube hydraulic transmission system, thus avoiding the trouble caused by the use of sucker rods. Various disadvantages.

[0013] The downhole hydraulic piston pump of the present invention includes a working cylinder 30 , a fixed valve 43 installed at the bottom of the working cylinder 30 , a transverse partition 45 and a double-piston structure capable of reciprocating movement in the working cylinder 30 . The transverse partition 45 is arranged on the middle and upper part of the working cylinder 30 so as to divide the working cylinder into upper and lower cavities. The upper moving valve 33 is located in the upper cavity, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com