Ecological restoration method for sintering-method red mud stacking area side slope

A technology of ecological restoration and sintering method, which is applied in botany equipment and methods, excavation, soil protection, etc., to achieve high efficiency, reduce environmental pollution problems, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

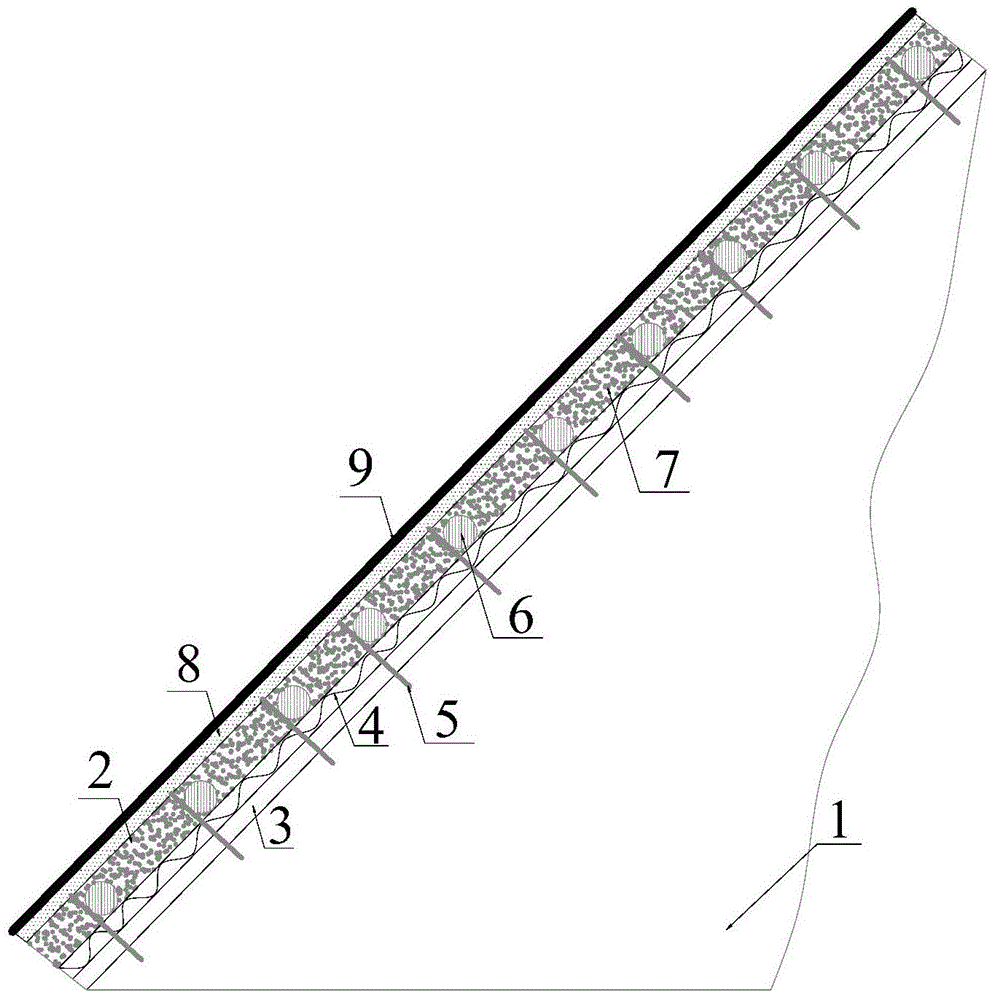

[0035] Zibo City, Shandong Province, Shandong Aluminum Co., Ltd. 1# red mud yard A test area, yard slope: 65-75°, pH value: 12.0. Follow the steps below in sequence (combining figure 1 Schematic diagram of the slope structure shown):

[0036] 1) Preparation of soil improvement layer: uniformly mix loam, furfural slag and binder (model A30 from Eisen, France), wherein the loam and furfural slag are mixed in a volume ratio of 3:7, and the binder Calculated based on the unit area to be sprayed, the specific dosage is 10g / m of adhesive 2 .

[0037] 2) Preparation of substrate layer: uniformly mix the greening substrate, loam, water-retaining agent and adhesive, wherein the greening substrate and loam are mixed according to the volume ratio of 2:8, and the water-retaining agent and adhesive are to be sprayed The unit area of sowing is calculated, and the specific dosage is 10g / m2 of adhesive 2 , water retaining agent 15g / m 2 .

[0038] 3) Prepare the seed layer: uniformly m...

Embodiment 2

[0051] Zibo City, Shandong Province, Shandong Aluminum Co., Ltd. 1# red mud yard B test area, yard slope: 65-75°, pH value: 12.0. Follow the steps in order:

[0052] 1) Preparation of soil improvement layer: uniformly mix loam, furfural slag and binder (model A30 from Eisen, France), wherein the loam and furfural slag are mixed at a volume ratio of 5:5, and the binder Calculated based on the unit area to be sprayed, the specific dosage is 15g / m of adhesive 2 .

[0053] 2) Preparation of base material layer: uniformly mix the greening substrate, loam, water-retaining agent (French Eisen MP3500KM) and adhesive, among which, the greening substrate and loam are mixed according to the volume ratio of 3:7, water retention The agent and adhesive are calculated on the basis of the unit area to be sprayed, and the specific dosage is 15g / m of adhesive 2 , water retaining agent 20g / m 2 .

[0054] 3) Prepare the seed layer: uniformly mix the greening matrix, loam, water-retaining age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com