High flame retardant nylon resin and its preparation method

A technology of nylon resin and flame-retardant nylon, which is applied in the field of flame-retardant nylon resin and its preparation, can solve the problems of complex molecular structure of flame retardants, unfavorable large-scale industrial production, high price, etc., achieve durable flame retardancy and reduce dosage , Improve the effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Below is the preparation method of implementation example and comparative example:

[0029] (1) The polymerization monomer, catalyst, reactive flame retardant, synergistic flame retardant, carbon forming agent and carbonization promoting agent are prepared into materials according to the above ratio.

[0030] (2) Put the prepared materials into the high-pressure reaction kettle, vacuumize, remove the air in the kettle, and react under the protection of high-purity nitrogen.

[0031] (3) Heat the reaction kettle, and start stirring after the temperature of the reaction kettle rises. The temperature of the reaction kettle is controlled at 200°C~300°C, the pressure of the kettle is controlled at 0.2Mpa~2.0Mpa, and the reaction is 1~12h.

[0032] (4) Open the pressure relief valve to reduce the pressure of the kettle to normal pressure, then vacuumize for 0.5~8h, and control the vacuum degree between -0.05~-0.1MPa.

[0033] (5) Finally, nitrogen is filled until the pressur...

Embodiment 1

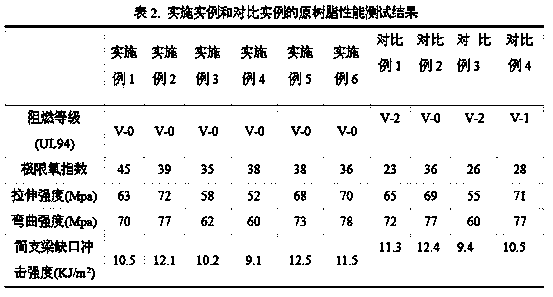

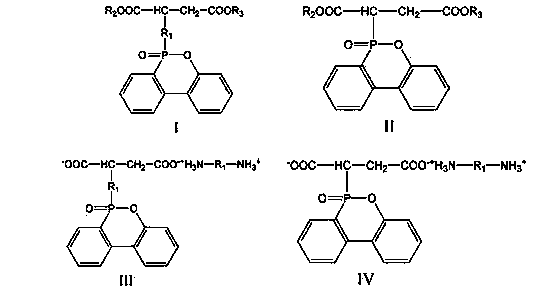

[0035] Embodiments 1, 2, 3, 4, 5, and 6 are flame-retardant nylon resins prepared by the present invention. Comparing the data in Table 1 and Table 2, it can be seen that the flame-retardant nylon prepared by the present invention has good mechanical properties. The oxygen index is high, and the flame retardant grade reaches UL 94 V-0 level. At the same time, further comparison can be seen: the flame retardant nylon obtained in Example 2 is compared with Example 6, and it can be seen that the reactive flame retardant must be at least doubled to To achieve the same flame retardant effect, so the price will be doubled; comparative example 3 is only adding a flame retardant that does not participate in the reaction, and the flame retardant grade and oxygen index are obviously worse than that of embodiment 3; comparative example 4 only adds a reactive flame retardant Flame retardant, compared with the embodiment 6 that adds synergistic flame retardant, the flame retardant effect ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com