Novel multifunctional deep hole drill oiler for lathe optimization

A multi-purpose, deep-hole drilling technology, applied in the direction of drilling/drilling equipment, manufacturing tools, boring/drilling devices, etc., to achieve the effect of strong adaptability, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

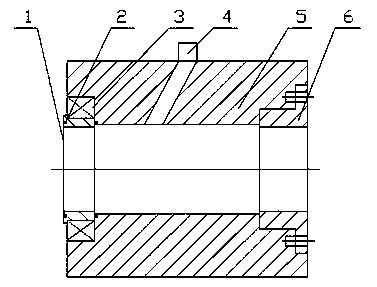

[0012] Example: such as figure 1 As shown, a new multi-purpose deep hole drilling oiler for lathe transformation, the oiler includes machine base 5, bearing 3, replaceable drill sleeve 1, cover plate 6, infusion nozzle 4 and sealing ring 2, cover plate 6 is connected to one end of the machine base 5, the other end of the machine base 5 is equipped with a bearing 3, the replaceable drill sleeve 1 passes through the sealing ring 2 and the bearing 3 and presses the inner ring of the bearing, and the high-pressure coolant enters the inner cavity of the machine base 5 through the infusion nozzle 4 , the replaceable drill sleeve 1 of the oil dispenser can rotate together with the workpiece and replace the drill sleeve according to different apertures, and the cover plate 6 and the replaceable drill sleeve 1 play a supporting and centering role.

[0013] When using this embodiment, the drill bit and the drill pipe pass through the cover plate 6 of the oiler, the inner cavity of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com