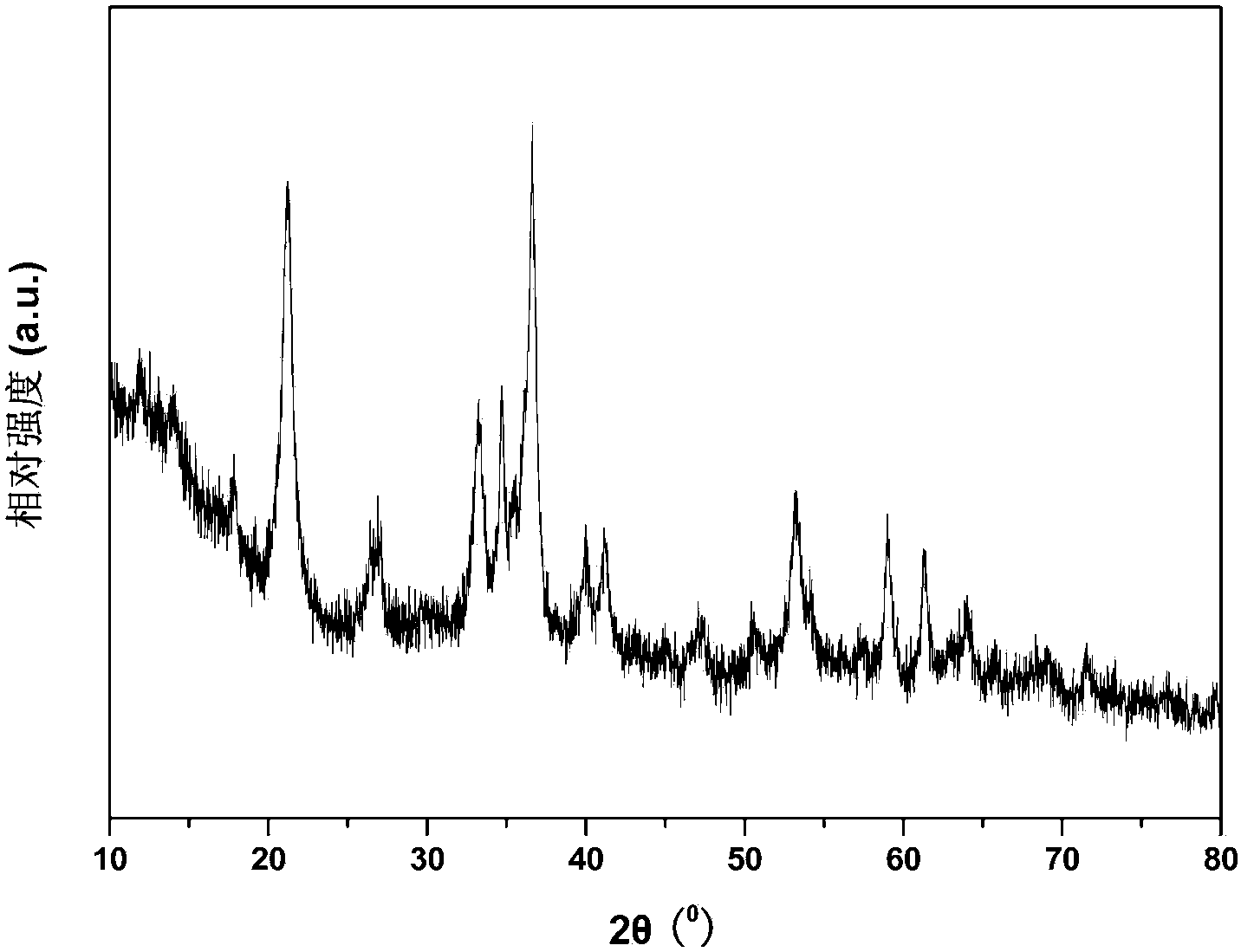

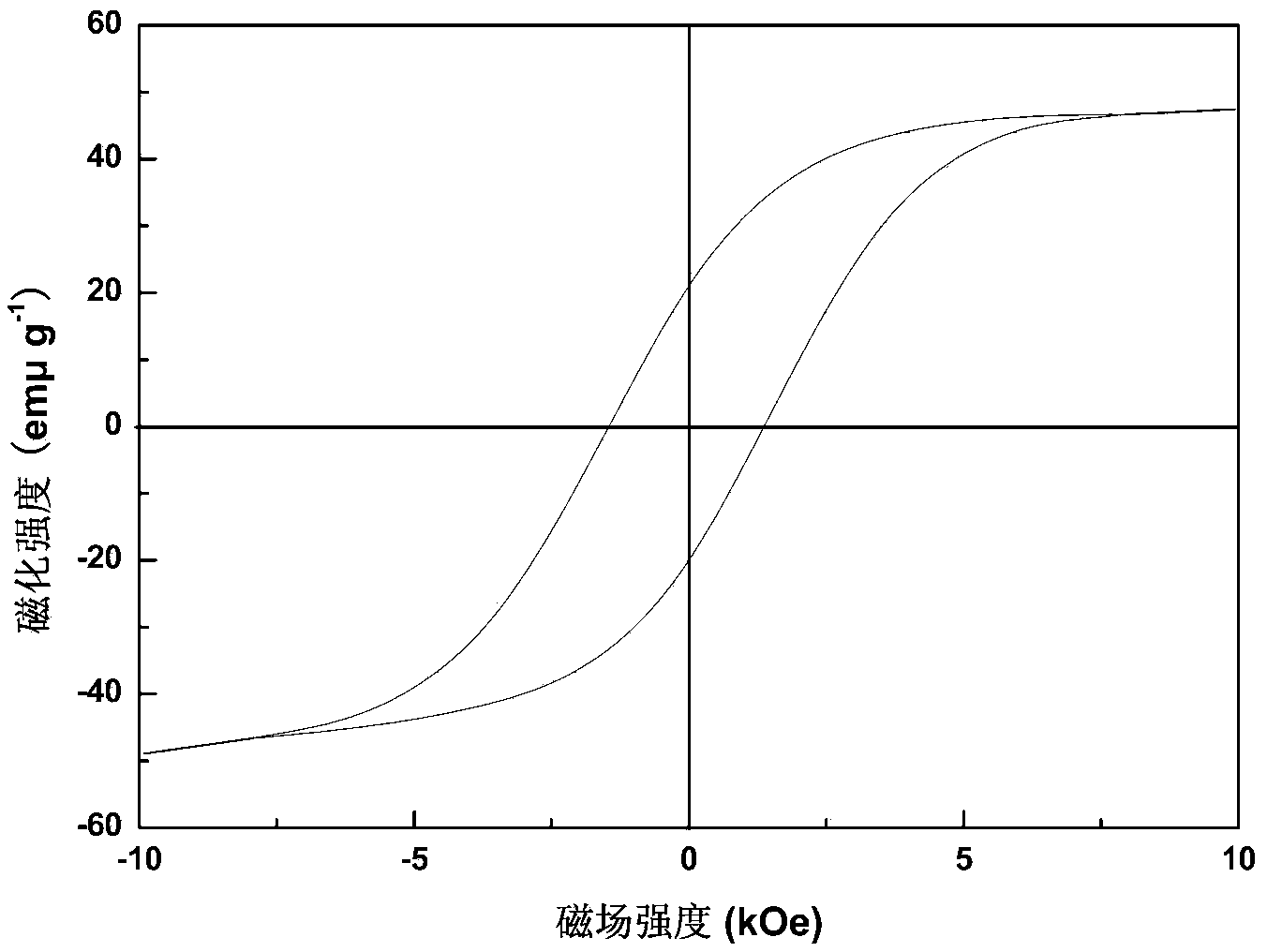

Synthetic method of iron-based magnetic nano goethite

A technology of magnetic nano and synthetic methods, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the difficult recovery of goethite catalysts, secondary pollution, etc. problem, to achieve the effect of easy magnetic properties, low cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: the synthetic method of iron-based magnetic nano-goethite in this embodiment is implemented according to the following steps:

[0027] 1. Dissolve the ferric salt in deionized water to prepare a ferric salt solution with a concentration of 0.2-2.0mol / L;

[0028] 2. Press nFe 2+ / nFe 3+ =0.01~0.25 Add ferrous iron salt to ferric salt solution, mix evenly to obtain mixed solution;

[0029] 3. Add the alkaline solution with a concentration of 0.5 to 2.0 mol / L dropwise into the mixed solution in step 2, and stir while adding dropwise until no precipitation occurs in the solution to obtain a suspension;

[0030] 4. Adjust the pH value of the suspension in step 3 to 9-12, leave it to settle for 60-120 minutes, and then activate it for 24-48 hours at a temperature of 40-80° C. to obtain a reaction mixture;

[0031] 5. Filter the reaction mixture obtained in step 4, wash the collected solid phase with distilled water until the pH of the washing solut...

specific Embodiment approach 2

[0035] Specific embodiment two: the difference between this embodiment and specific embodiment one is that step two press nFe 2+ / nFe 3+ =0.03~0.1 Add ferrous salt to ferric salt solution. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that step 3 uses magnetic stirring, and the stirring speed is 100r / min-200r / min. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com