Cascading-type pulse tube refrigerator capable of recycling sound power

A pulse tube refrigerator, cascading technology, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problems of low efficiency of the whole machine, ineffective energy saving, dissipation, etc., and achieve maximum utilization Space, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

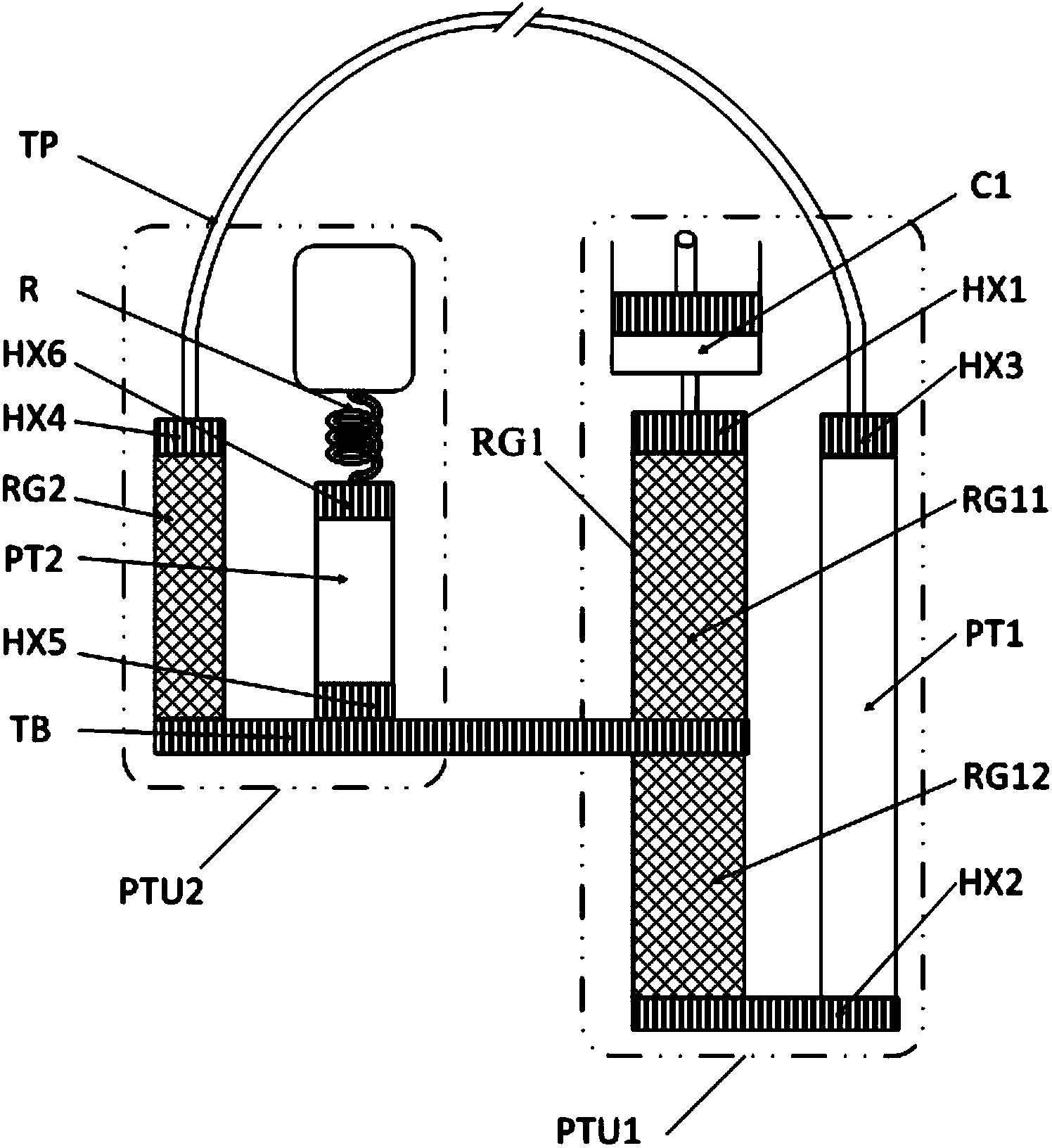

[0031] use figure 1 The structure shown is a cascaded pulse tube refrigerator that recovers sound power, including a main-stage pulse tube refrigerator unit PTU1 and an auxiliary-stage pulse tube refrigerator unit PTU2, and the main-stage pulse tube refrigerator unit PTU1 includes a main-stage compression Engine C1, main-stage aftercooler HX1, main-stage regenerator RG1, main-stage cold-end heat exchanger HX2, main-stage pulse tube PT1, main-stage hot-end heat exchanger HX3. The auxiliary-stage pulse tube refrigerator unit PTU2 includes auxiliary-stage aftercooler HX4, auxiliary-stage regenerator RG2, auxiliary-stage cold-end heat exchanger HX5, auxiliary-stage pulse tube PT2, auxiliary-stage hot-end heat exchanger HX6 and phase modulation Element R. The main-stage hot-end heat exchanger HX3 is connected to the auxiliary-stage aftercooler HX4 through the transfer pipe TP. The auxiliary cold end heat exchanger HX5 cools the main regenerator RG1 through the thermal bridge TB. T...

Embodiment 2

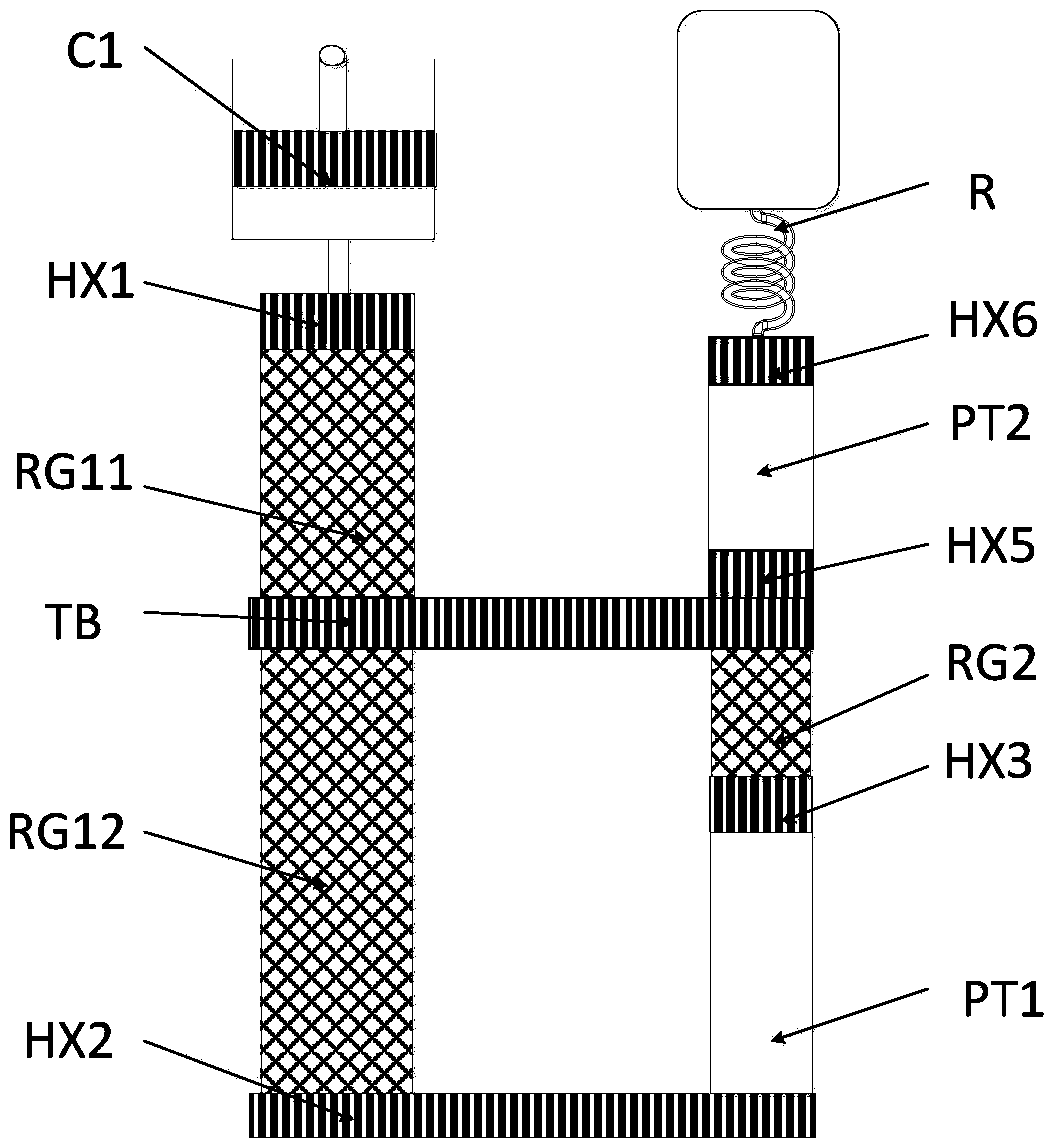

[0044] use figure 2 The difference between the structure shown and the first embodiment is that the cascaded pulse tube refrigerator that recovers sound power can remove the transfer tube TP, remove the main stage hot end heat exchanger HX3 or the auxiliary stage aftercooler HX4, and others The structure remains unchanged, this structure can also recover part of the sound work.

[0045] The invention can also connect N auxiliary-stage pulse tube refrigerator units in sequence without a transfer tube, and analogously, can form a system with N auxiliary-stage pulse tube refrigerator units, where N is generally greater than or equal to 2 and less than An integer equal to 10, each auxiliary-stage pulse tube refrigerator unit includes auxiliary-stage aftercooler, auxiliary-stage regenerator, auxiliary-stage cold-end heat exchanger, auxiliary-stage, pulse tube, auxiliary-stage hot-end heat exchanger, Among the two auxiliary pulse tube refrigerator units connected in sequence, the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com