A kind of anti-collision device for heavy photoelectric equipment

A technology of optoelectronic equipment and bumper, applied in the direction of non-rotational vibration suppression, etc., can solve the problem of no report of heavy optoelectronic equipment side bumper device, and achieve the effect of increasing mutual gap, maintaining stability and eliminating mutual gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

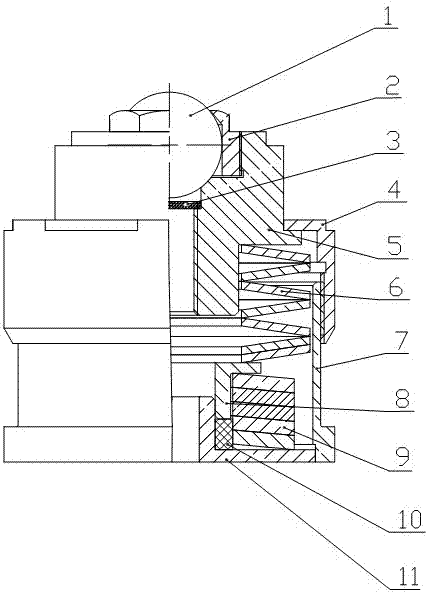

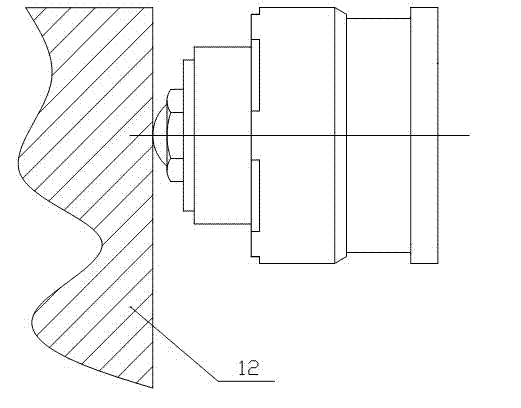

[0018] Such as figure 1 As shown, the anti-collision device for heavy-duty photoelectric equipment of the present invention, the main body is based on the shell 7, the upper end of the shell is threaded to install the screw cap 4, and the center of the screw cap top is provided with a hole, the connector 5 penetrates into the hole, and through the connecting The side flange of the head 5 is positioned with the screw cap 4 . There is a stepped hole on the upper part of the connecting head, and the oil tray 3 and the steel ball 1 are installed in the stepped hole, and the steel ball 1 is fixed and adjusted by screwing in the pressure ball cover 2. There is a stepped shaft at the lower part of the connecting head, and a set of discs A 6 are enclosed within the outer edge of the step shaft in the way of facing and reversed between two; the base plate 11 is installed at the bottom of the shell 7, and a tubular wire mesh pad 10 is housed between the base plate 11 and the anti-punchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com