Supersonic-peed blade profile for turbine blades

A steam turbine blade, supersonic technology, applied in the direction of blade support elements, mechanical equipment, engine elements, etc., can solve the problems of blade profile loss, high Mach number at the outlet of stationary blades and moving blades, shock loss, etc. type loss, reduce shock loss, weaken the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

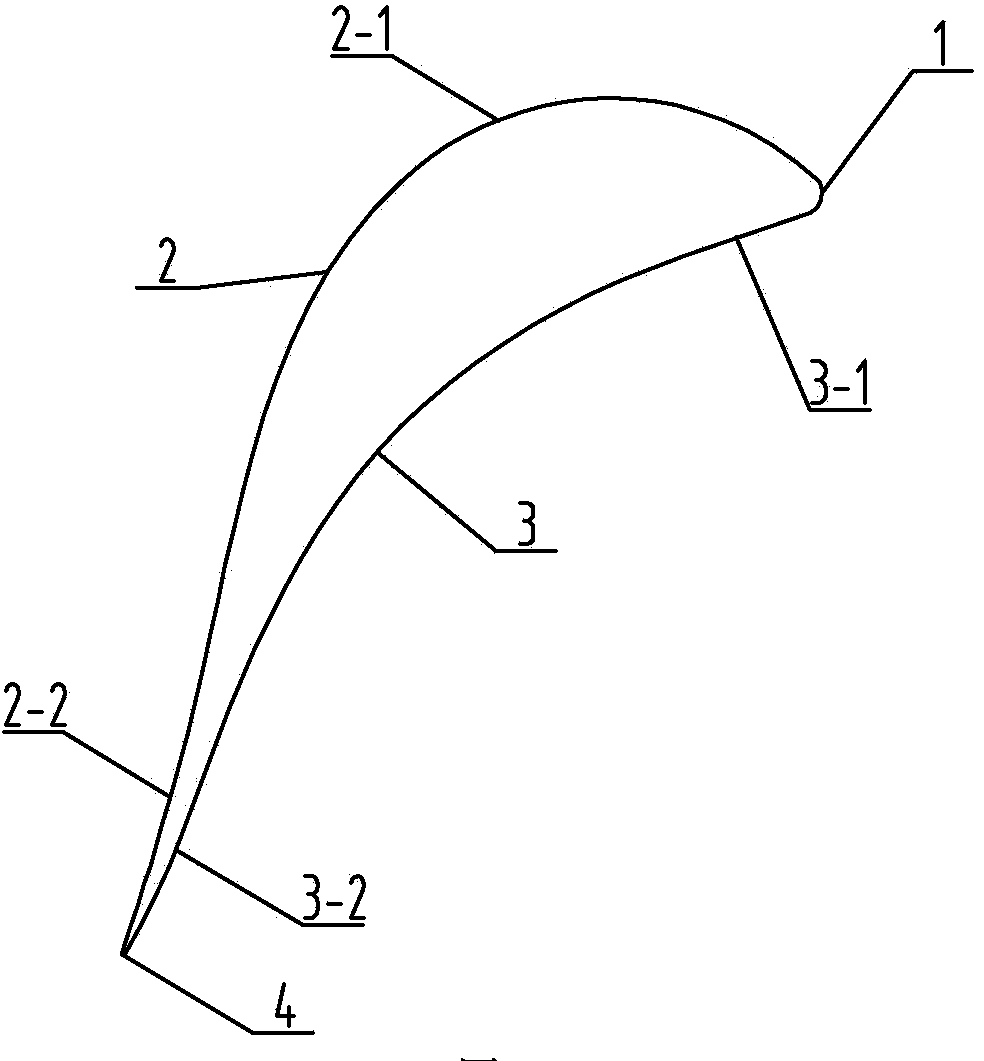

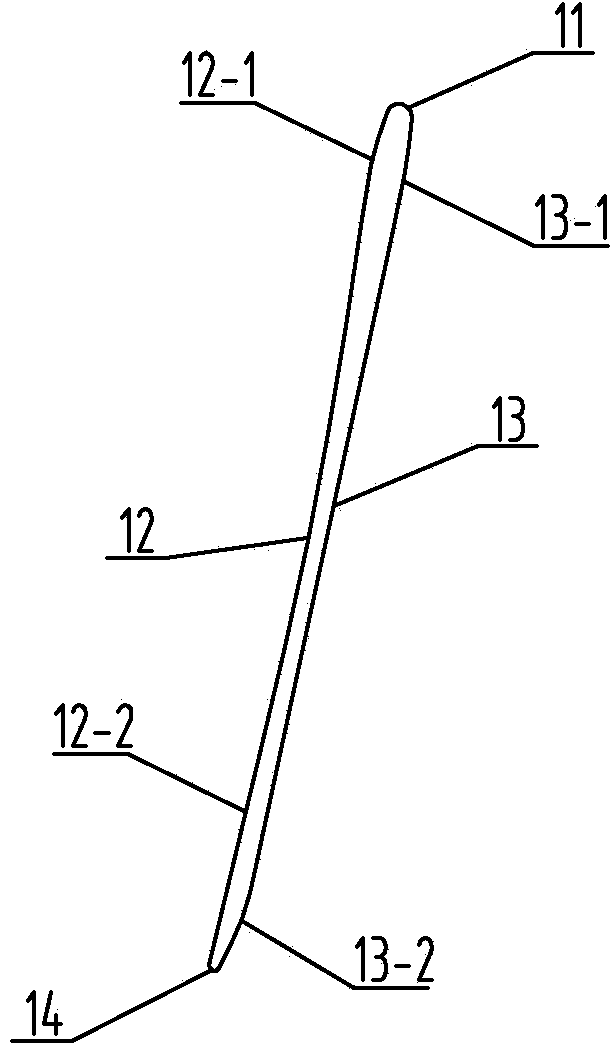

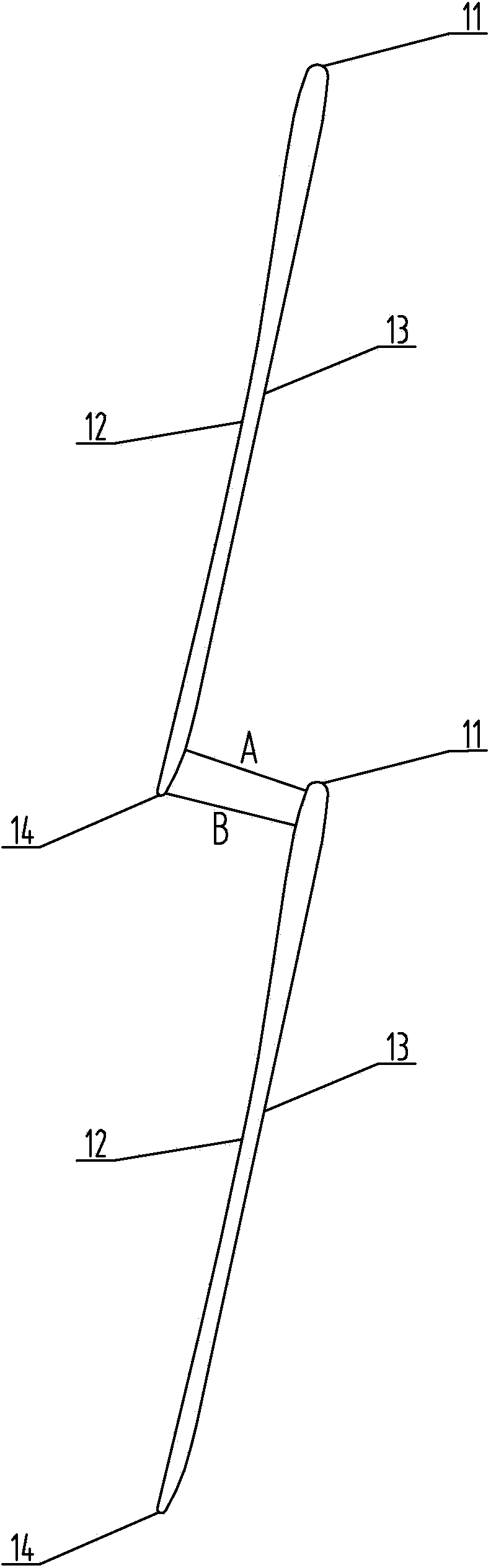

[0020] Specific implementation mode one: combine Figure 1 to Figure 6 This embodiment is described. In this embodiment, the steam turbine blade is a variable cross-section twisted blade from top to bottom. The blade is viewed from the cross section: the blade shape in the middle and lower part of the blade consists of the lower air intake edge 1, the lower back arc 2, the lower inner arc 3 and the lower inner arc. The air outlet side 4 is composed of the lower air inlet side 1, the lower back arc 2, the lower air outlet side 4 and the lower inner arc 3 connected end to end in sequence, the lower air inlet side 1 and the lower air outlet side 4 are circular arcs, and the lower air outlet side 4 The arc is smaller than the arc of the lower air intake edge 1, the side of the lower back arc 2 near the lower air intake edge 1 is an outwardly large convex arc 2-1, and the side of the lower back arc 2 near the lower air outlet edge 4 is The downward and inward small concave arc 2-2,...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination Figure 5 The present embodiment will be described. The mounting angle β of the blade profile of the present embodiment is 10° to 45°. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination Figure 5 The present embodiment will be described. The mounting angle β of the blade profile of the present embodiment is 20°. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com