A Composite Retaining Structure Combined with Reinforced Soil Structure and Anti-slide Pile

A retaining structure and reinforced soil technology, which is applied in underwater structures, foundation structure engineering, water conservancy engineering, etc., can solve the problem of increasing the embedding and occlusal effect of soil particles, the natural grading and stacking of slopes that cannot be filled, It is not suitable to apply to problems such as flooded areas, so as to achieve remarkable engineering effects, increase the site area, and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

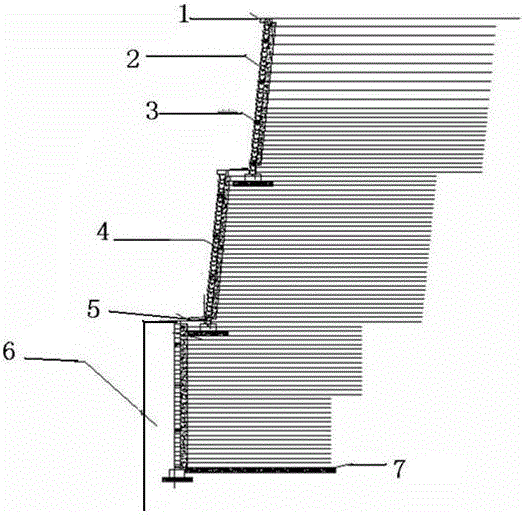

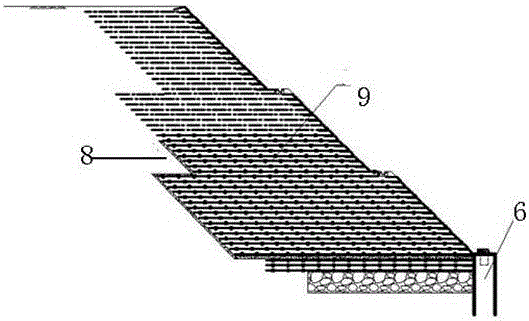

[0023] In the composite structure combining the reinforced soil structure and the anti-slide pile of the present invention, the upper filling that the anti-slide pile resists is the reinforced soil structure and its rear filling, and the reinforced soil structure can be adjusted according to the slope of the slope. It is divided into two structural forms: reinforced soil slope and reinforced soil retaining wall. The anti-slide pile is located at the bottom wall toe or slope toe of the reinforced soil structure, and resists the sliding of the upper reinforced soil structure and its back filling. When the upper reinforced soil structure is a reinforced soil retaining wall structure, the position of the anti-slide pile is set at the toe of the reinforced soil retaining wall. When the upper reinforced soil structure is a reinforced soil slope structure, the position of the anti-slide pile is set at the toe of the reinforced soil slope. When the upper reinforced soil structure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com