Leakage stoppage device used on naval vessels

A leak stopper and naval vessel technology, which is applied to the safety, transportation and packaging of naval vessels and ships, and can solve the problems of directly hitting the human body, unrecorded and unseen in patent documents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

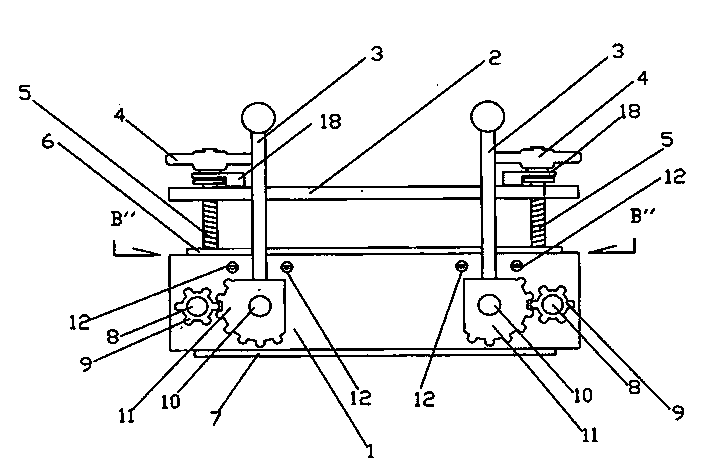

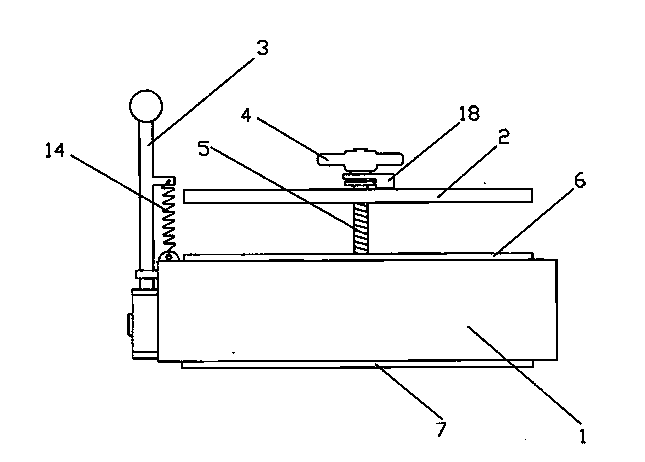

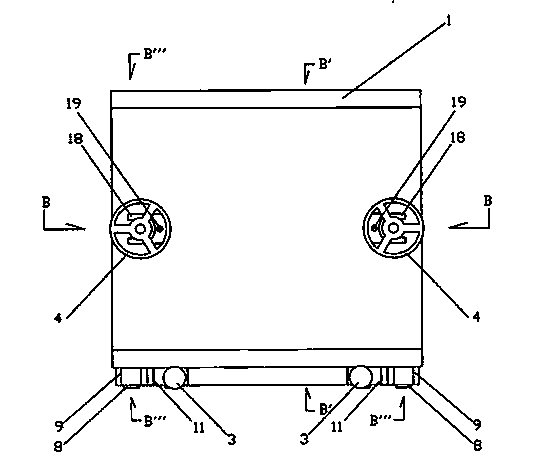

[0024] Attached below figure 1 , attached drawing 2, attached drawing 3, attached drawing 4, attached drawing 5, attached drawing 6, attached drawing 7, attached drawing 8, attached drawing Figure 9 , attached Figure 10 , attached Figure 11 Further description of the embodiment of the present invention: a leak stopper used on ships, the upper part of the square leak stopper seat 1 has a sealing plate 2 that can move up and down, and there is a sealing plate 2 on the left and right sides of the sealing plate 2. The sealing plate aperture 20 that screw 5 passes, the sealing plate hook 18 is installed above the sealing plate aperture 20, and screw 19 is fixed on the sealing plate hook 18 on the sealing plate 2. One end of the screw 5 passes through the central part of the seal plate hook 18 and the small hole 20 of the seal plate, and is fixed on the seat body 1 of the leak stopper, and the other end is bolted with a disc bolt 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com