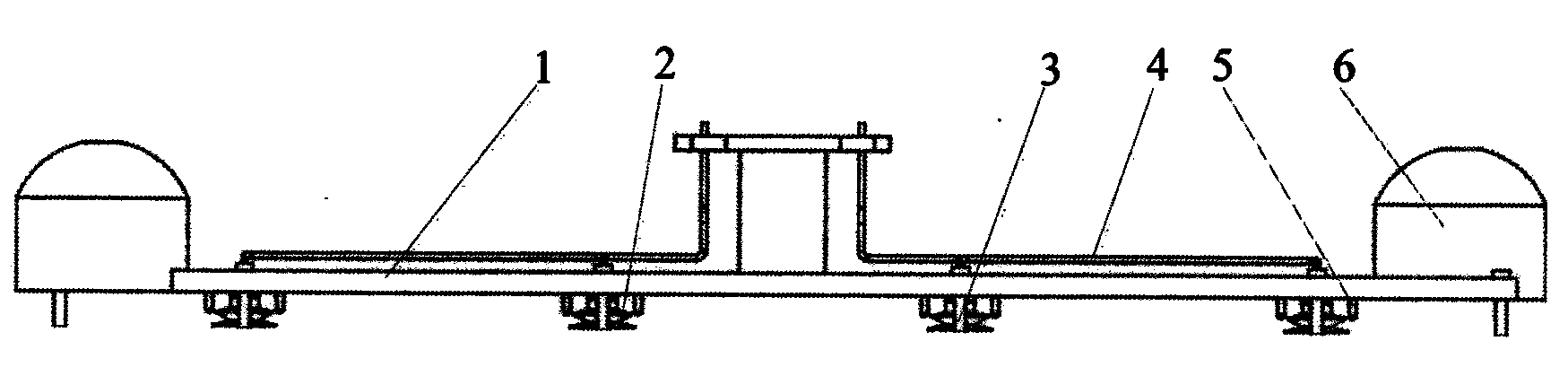

Planar-location vacuum absorption fixture used for cutting flat-plate-like parts

A plane positioning and vacuum adsorption technology, which is applied in metal processing and other directions, can solve the problems that affect the processing accuracy, difficulty in guaranteeing, and the workpiece is thrown out of the fixture, so as to achieve the effect of improving processing accuracy and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

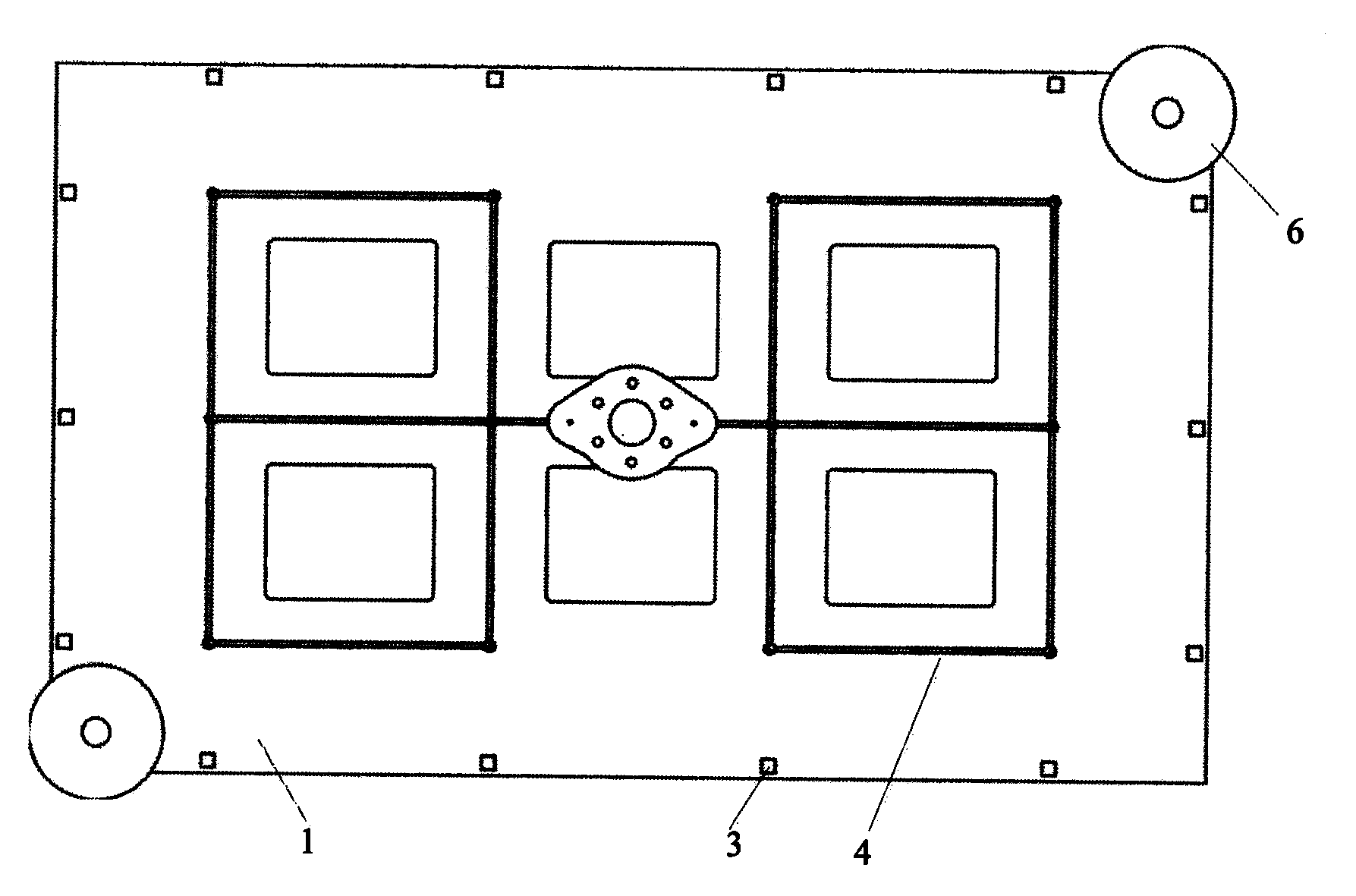

[0029] by Figure 5 The wooden board shown should be cut into 6 pieces of A1, A2, A3, A4, A5, A6, etc. as an example, and 9 is the printed feature on the board. Figure 5 There are printed feature upper right corner point 7 and printed feature lower left corner point 8 for positioning. The method of using the vacuum adsorption fixture capable of plane positioning for cutting flat-plate parts provided by the present invention is as follows:

[0030] Move the vacuum adsorption fixture above the plate to be cut;

[0031] Press down the vacuum adsorption fixture, start the suction cup to absorb the sheet;

[0032] Start the machine vision to identify the corner position of the printing feature;

[0033] Recalculate the target position, move the vacuum adsorption fixture to the first cutting station, align the cutter with the printed features, and press down the vacuum adsorption fixture to the workbench;

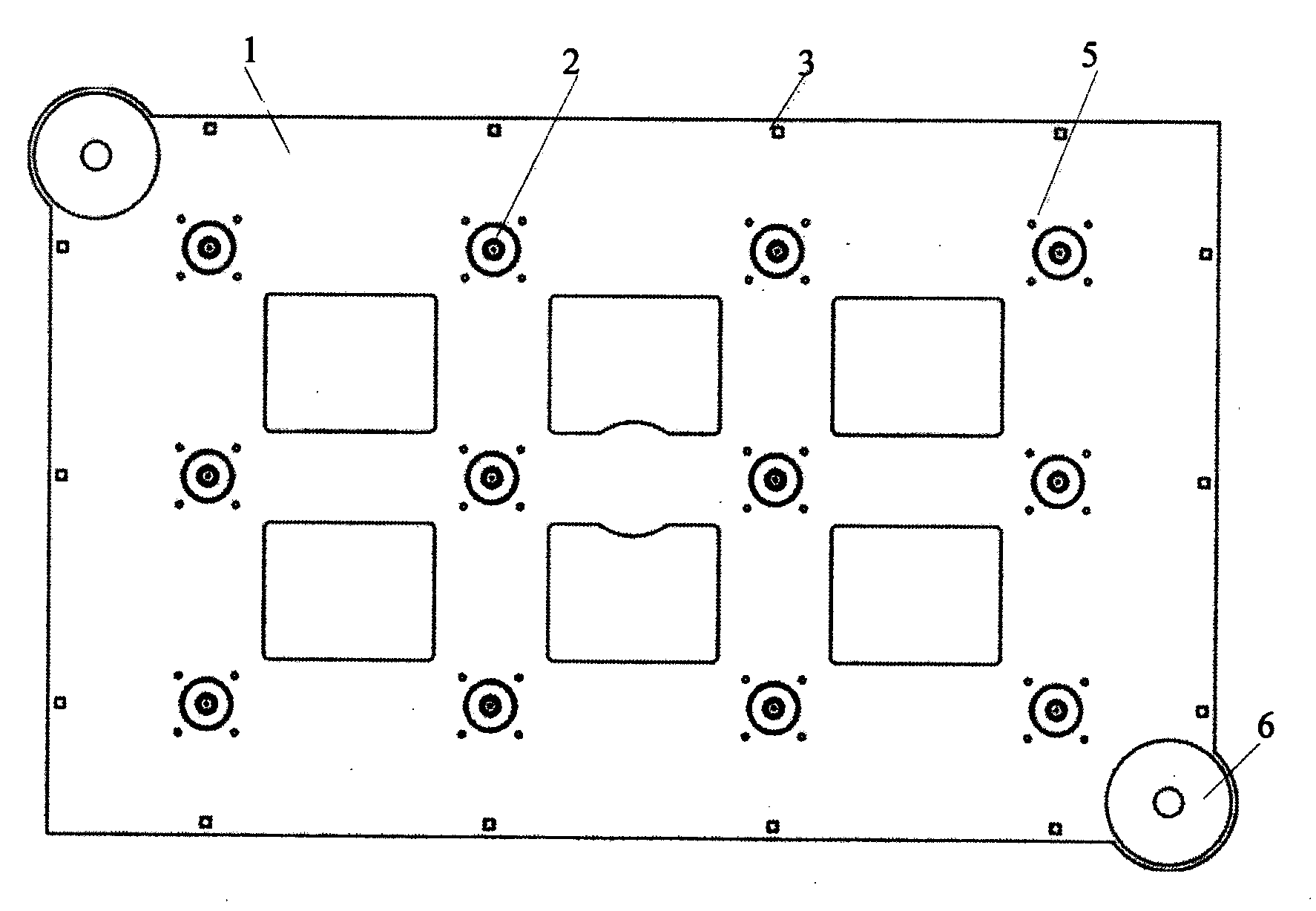

[0034] The first cut, cut as Figure 6 As shown, multiple cutters cut ...

Embodiment 2

[0038] Also to Figure 5 The wooden board shown should be cut into 6 pieces of A1, A2, A3, A4, A5, A6 as an example, without machine vision, Figure 5 There is no printed feature upper right point 7 and printed feature lower left point 8 in . The method of using the vacuum adsorption fixture capable of plane positioning for cutting flat-plate parts provided by the present invention is as follows:

[0039] Move the vacuum adsorption fixture above the plate to be cut;

[0040] Press down the vacuum adsorption fixture, start the suction cup to absorb the sheet;

[0041] Move the vacuum adsorption fixture to the first cutting station, and press down the vacuum adsorption fixture to the workbench;

[0042] The first cut, cut as Figure 6 As shown, multiple cutters cut in one direction at the same time; so that the plate cutting is divided into two parts: A1-A2-A3 and A4-A5-A6 except for waste;

[0043] The vacuum adsorption fixture rises and moves to the second cutting station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com