Air cooling device used after steel band plastic coating

An air-cooling device and plastic coating technology, which can be applied to devices for coating liquid on surfaces, coatings, surface pretreatment, etc., can solve problems such as noise pollution of the working environment, and achieve improved site environment, low noise, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

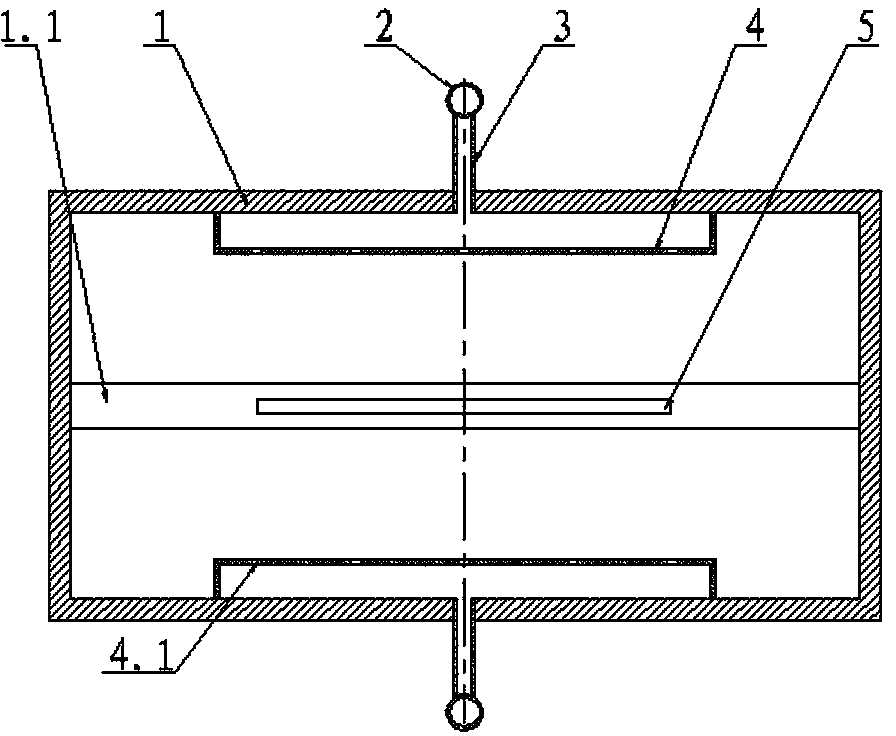

[0015] figure 1 The air-cooling device shown is used for plastic-coated steel strips, which includes a housing 1, an air duct 2, a connecting pipe 3 and an air chamber 4. The shell 1 is a rectangular shell, which is the main component of the air cooling device. The flat shell 1 is placed between the steel strip plastic coating section and the winding section of the polyethylene pipe production line in the length direction, and the plastic coated steel strip passing through 5 runs through the shell 1 through the open slot 1.1 centered at both ends, that is, the plastic-coated steel strip 5 enters from the open slot 1.1 at the right end of the shell 1, and then passes through the open slot 1.1 at the left end of the shell 1. The air chamber 4 is rectangular, and the upper and lower inner walls of the housing 1 are equidistantly arranged along the longitudinal direction of the air chambers 4. In this embodiment, because the plastic-coated steel belt is only 57.5mm, the front and ...

Embodiment 2

[0017] In this embodiment, since the plastic-coated steel has a bandwidth of 182 mm, the stored heat is large, and more compressed air is required for cooling, so a larger size and a larger number of air injection holes 4.1 are selected. On the basis of the same structure, the air chamber 4 in this embodiment is provided with five jet holes 4.1 with a diameter of Ф20 mm, so that the technical effect similar to that of the embodiment 1 can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com