A System for Precisely Controlling the Uniformity of Ion Implantation

A technology of ion implantation and uniform distribution, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of inability to meet uniformity and parallelism, unable to obtain broadband beams, etc., and achieve the effect of simple structure, reliable function, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

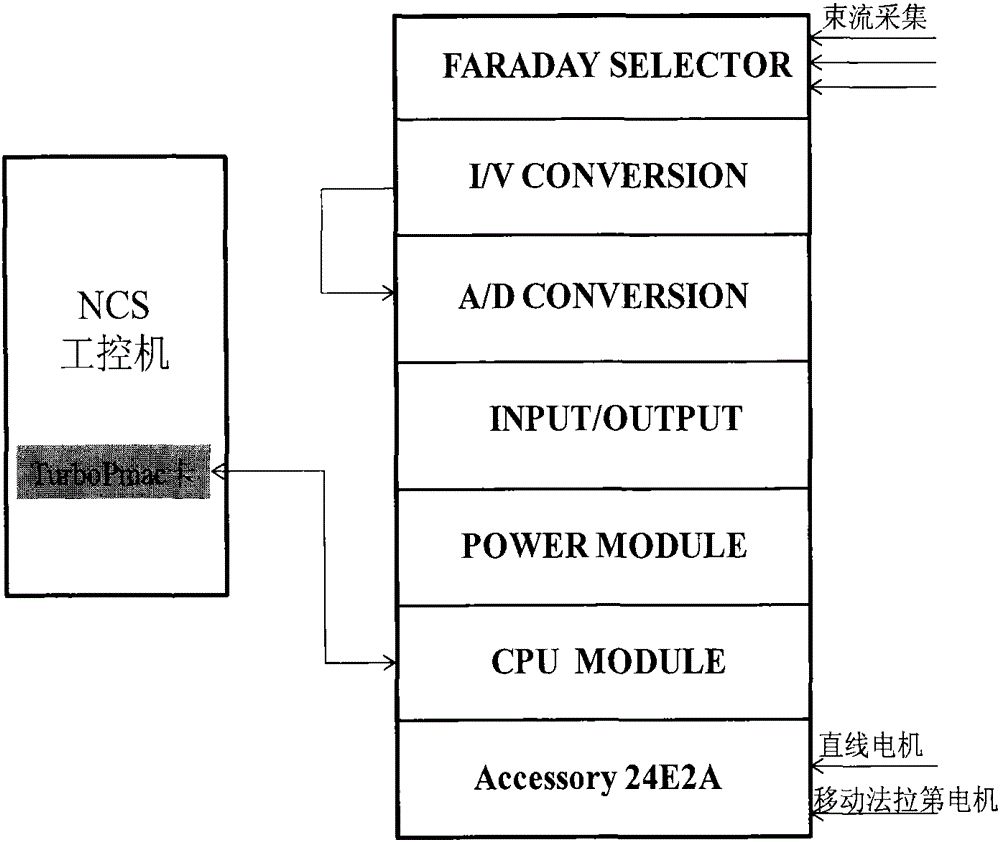

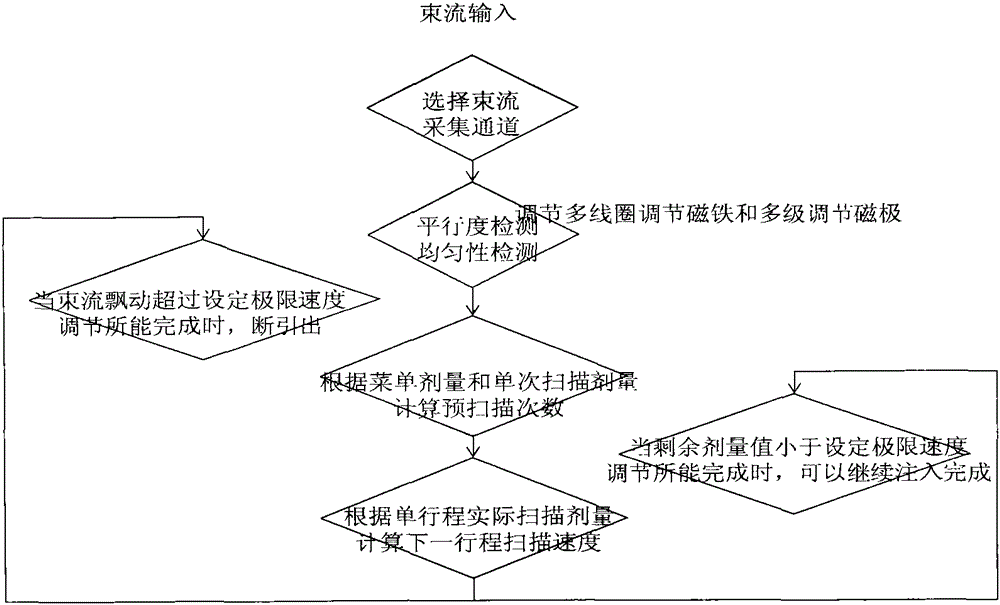

[0019] Attached below figure 1 And attached figure 2 The present invention is further introduced, but not as a limitation to the present invention.

[0020] like figure 1 As shown, a system for precisely controlling the uniform distribution of ion implantation involves high-precision multi-channel I / V acquisition conversion, detection and correction of beam distribution density in the horizontal direction, beam parallelism detection, and vertical scanning control algorithm; the system is mainly composed of multi-coil It consists of adjusting magnet, multi-stage adjusting magnetic pole, moving Faraday cup, sampling Faraday cup, linear motor and PMAC motion control system.

[0021] The extracted broadband beam is adjusted by the multi-coil adjustment magnet installed at the entrance of the wide-beam parallel lens and the multi-level adjustment magnetic pole installed at the exit of the wide-beam parallel lens to ensure the uniformity and parallelism of the broadband beam. Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com