Novel air cylinder quality verification device

A quality inspection and cylinder technology, applied in the direction of measuring devices, liquid tightness measurement using liquid/vacuum degree, instruments, etc., can solve the problems of low detection efficiency of detection devices, damage to cylinder quality, complex equipment structure, etc., and achieve maintenance The effect of convenient and quick repair, reduced maintenance cost and high inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of a new type of cylinder quality inspection device will be described in detail below in conjunction with the examples and accompanying drawings, but the specific implementation of the present invention is not limited to the following examples.

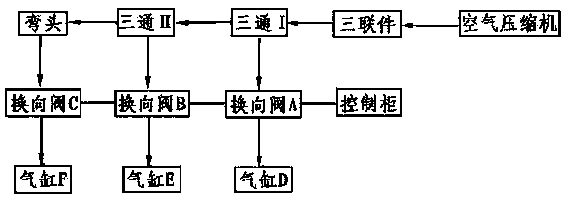

[0019] Such as figure 1 As shown, the basic process of the cylinder inspection device is that the air compressor supplies air to the cylinder through the triple piece, the tee and the elbow, and the control cabinet adjusts the direction of the airflow entering the cylinder through the reversing valve, so as to control the movement of the cylinder rod. the goal of.

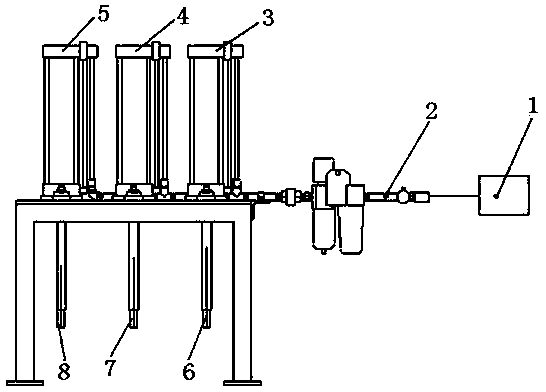

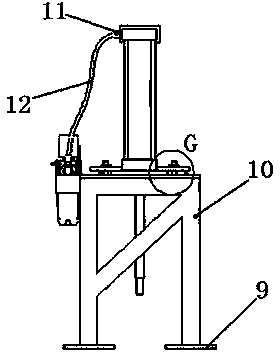

[0020] Such as figure 2 , as shown in 3 and 4, the air circuit 2 is fixed on the inspection platform frame 10 through the air circuit bracket 13, the air flow inlet end is connected with the air compressor 1, and the air flow out end is connected with the hose 12, and the hose 12 passes through the quick connector 11 They are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com