Method for detecting shape of large-diameter vertical shaft hole

A detection method and large-diameter technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve problems such as difficult to effectively detect the shape of large-diameter shaft holes, expand the scope of use, ensure the construction period, and the method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] In a shaft project of an iron mine, the diameter of the hole is 5.4m, the net diameter of the shaft is 4.0m, and the depth of the hole is 59.11m. The vertical shaft adopts mechanical graded drilling to form holes, the reinforced concrete shaft wall is permanently supported, and the cement slurry wall is filled to stop water. The real-time detection of the hole shape of the wellbore is detected by an ultrasonic hole shape detector. Since the diameter of the hole designed for this project is 5.4m, and the measurable diameter of the ordinary ultrasonic hole detector used is generally not greater than 4.0m, it is impossible to realize the full well The hole shape detection of wall utilizes the hole shape detection method of the present invention, and the specific implementation process is as follows:

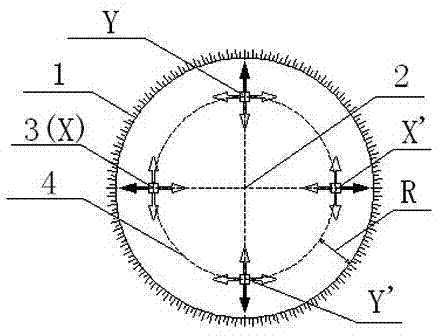

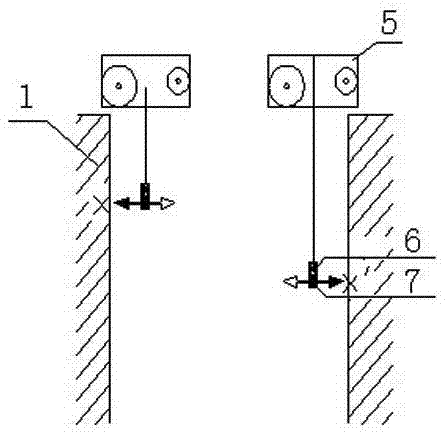

[0026] 1. See figure 1 , with the center point 2 of the wellbore opening as the center of the coordinate circle, two concentric wellbores are set, namely the outer center we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com