A kind of preparation method of low-voc polypropylene resin

A polypropylene resin and extraction technology, applied in the field of preparation of low-VOC polypropylene resin, can solve the problems of heating volatilization of repellent, reduction of effective time, reduction of VOC repelling effect, etc., and achieve the effect of simple and reliable operation process and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

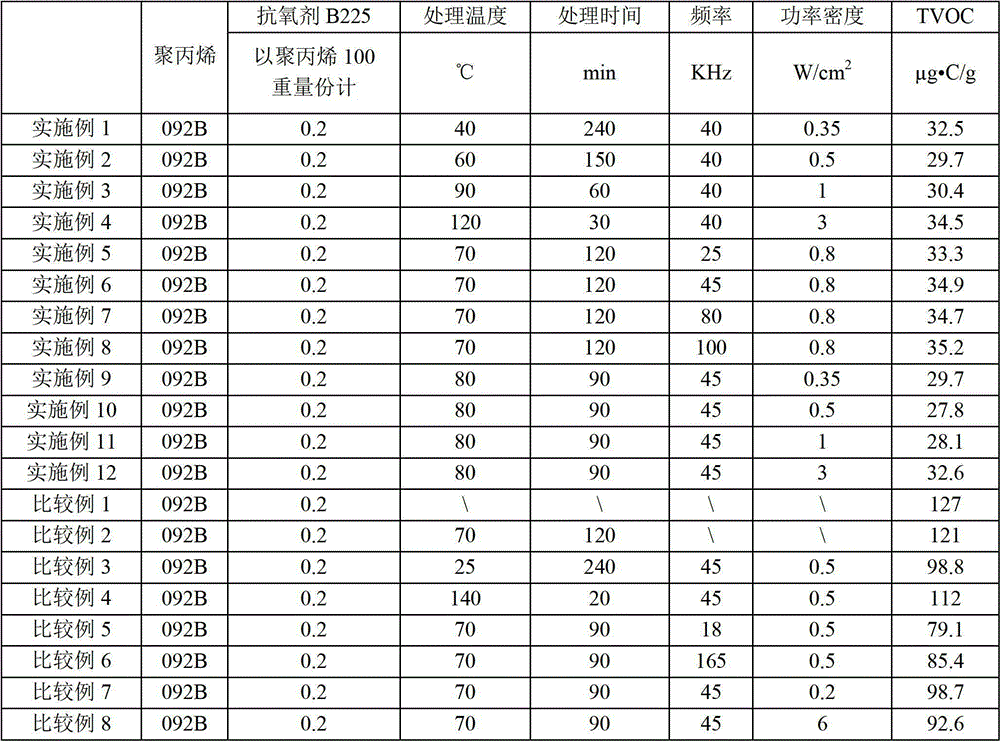

Embodiment 1~12

[0025] The raw material polypropylene: polypropylene powder (092B, produced by the pilot test base of Beijing Research Institute of Chemical Industry) is ultrasonically extracted by an industrial ultrasonic cleaner (Kunshan Ultrasonic Instrument Co., Ltd.) in a water bath, and then the polypropylene powder is placed in a vacuum Vacuum drying in an oven to obtain dry polypropylene powder; then put the treated polypropylene powder and processing aids (antioxidant B225, BASF, Germany) into a high-speed mixer, at a speed of 300 rpm Stir for 3 minutes to fully mix the components; then add the above-mentioned mixture from the feed port, and pass through the BUSS mixing unit (MKD-30, Swiss BUSS company) in the range of 190 ° C to 220 ° C, while maintaining the vacuum Under the condition of -0.08MPa, the low-VOC polypropylene resin is obtained by melt blending, extruding and granulating. Its specific formula and process parameters are shown in Table 1, wherein the content of each comp...

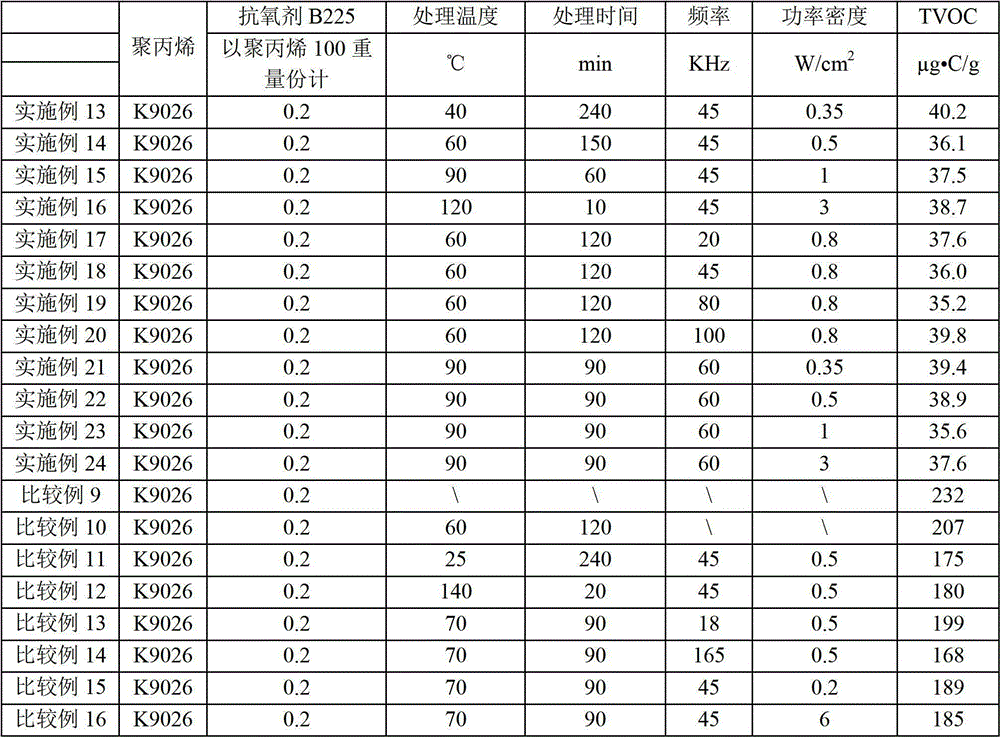

Embodiment 13~24

[0035] The raw material polypropylene: polypropylene resin (K9026, Sinopec Yanshan Branch) was ultrasonically extracted by an industrial ultrasonic cleaner (Kunshan Ultrasonic Instrument Co., Ltd.) in a water bath, and then the polypropylene was vacuum-dried in an oven to obtain dry Polypropylene resin; Put the processed polypropylene resin and processing aid (antioxidant B225 with embodiment 1) etc. into the high-speed mixer afterwards, stir for 3 minutes at a speed of 300 rpm, and make each component Mix thoroughly and evenly; then add the above-mentioned mixed materials from the main material inlet, pass through the BUSS mixing unit (MKD-30, Swiss BUSS company) in the range of 190 ° C to 220 ° C, and melt together under the condition of maintaining a vacuum degree of -0.08 MPa. Mixing, extrusion and granulation to obtain low VOC polypropylene resin. Its specific formula and process parameters are shown in Table 2, wherein the content of each component is calculated in parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com