Spring grinding mechanism

A technology of grinding and combined mechanism, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece planes, grinding workpiece supports, etc. It can solve the trouble of adjusting bearing interference, affect the vertical accuracy of springs, and affect the Grinding accuracy and other issues, to achieve the effect of improving grinding accuracy and stability, high production efficiency, and low grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following combined with the attachment and the specific embodiments further explained the present invention.

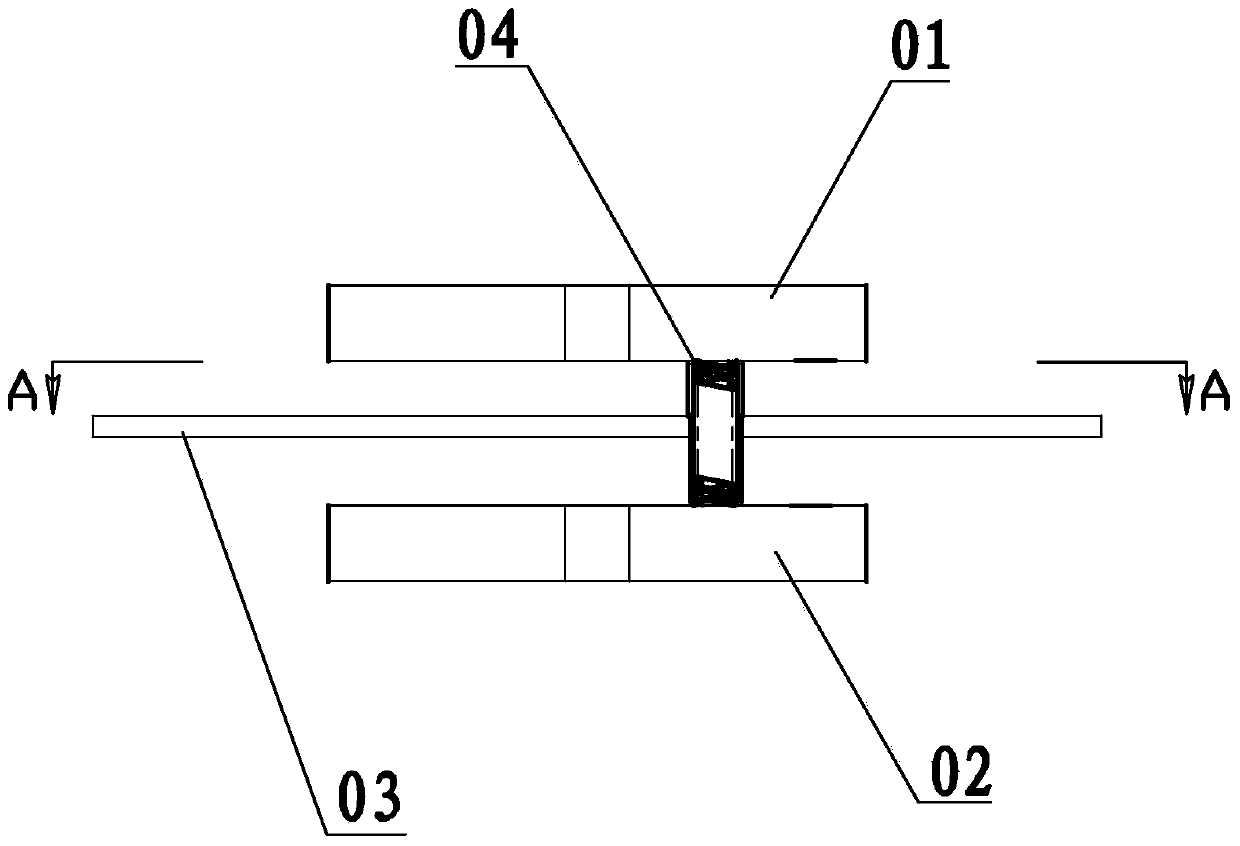

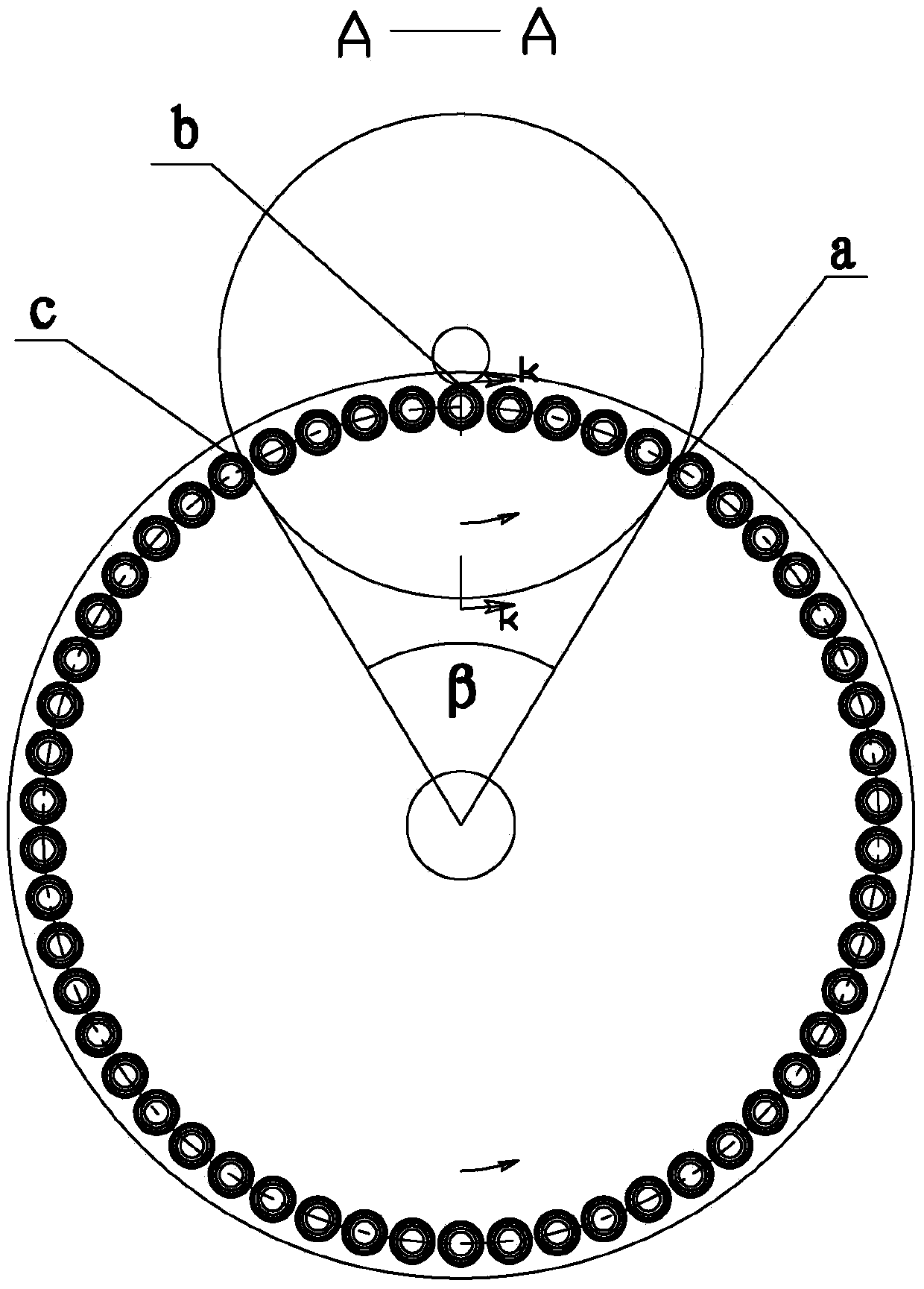

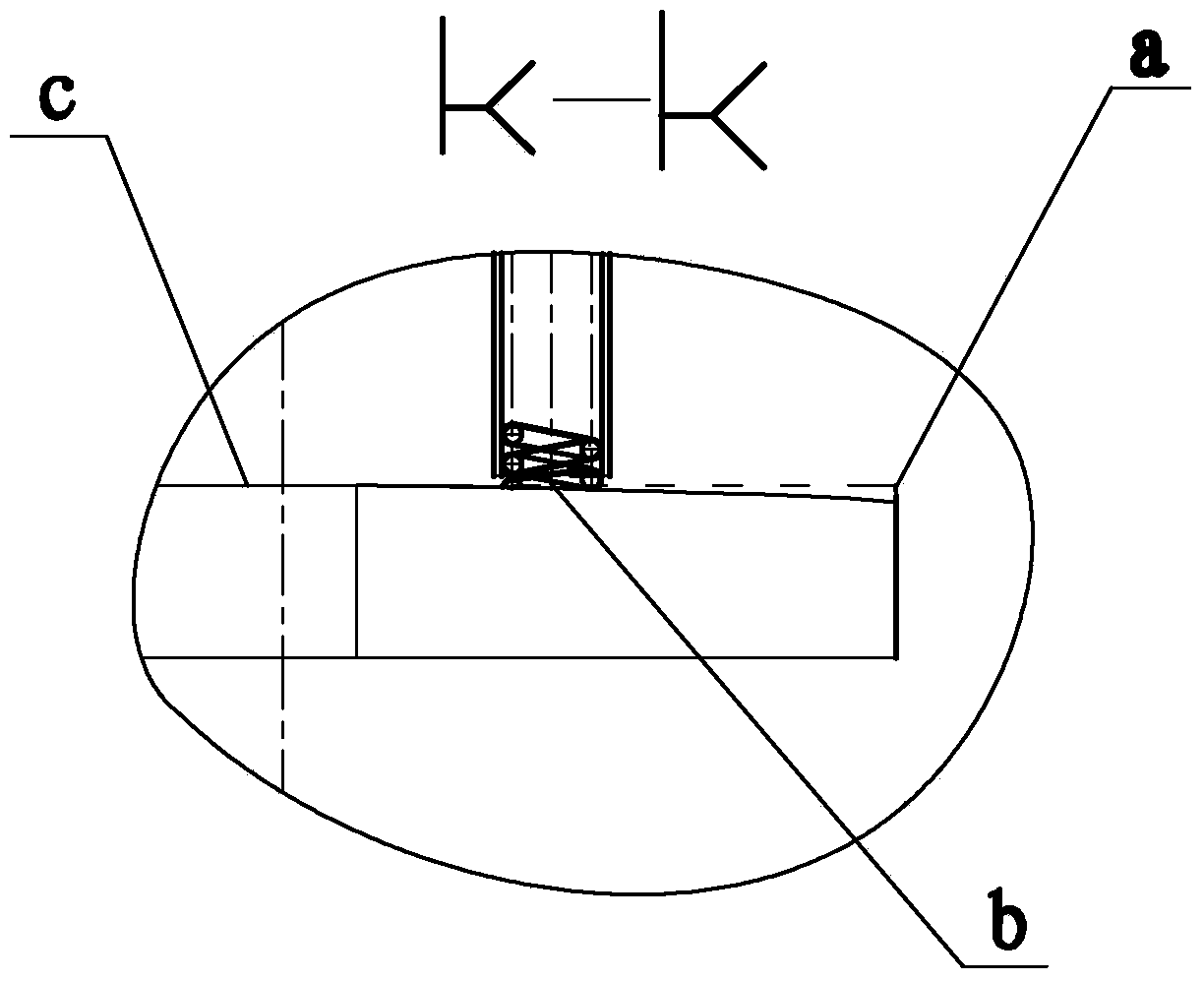

[0044] As shown in the figure, a spring grinding method and institutions revealed by the present invention, including the sand wheel 1, the lower sand wheel 2.In the example, the upper sand wheel 1 is selected as an integrated structure. The lower sand wheel 2 consists of the inner sand wheel 21 and the outer sand wheel 24. The outer diameter size of the inner sand wheel is slightly smaller than the outer sand wheel 24 inner diameter.The inner sand wheel 21 is the opposite of the rotation direction of the outer sand wheel 24. The outer sand wheel 24 is the same as the rotation direction of the upper wheel 1.The tray is installed in the inner hole to hold the spring when the spring in and out of the two sand wheels.

[0045] The grinding plate 3 is installed on the connecting rod of the swing mobile group 5, and the springs are installed on the grinding plate 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com