Numerical control system reliability rapid Bayes evaluation system under degradation tests

A numerical control system and reliability technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of unbearable test cost and test cycle, low reliability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

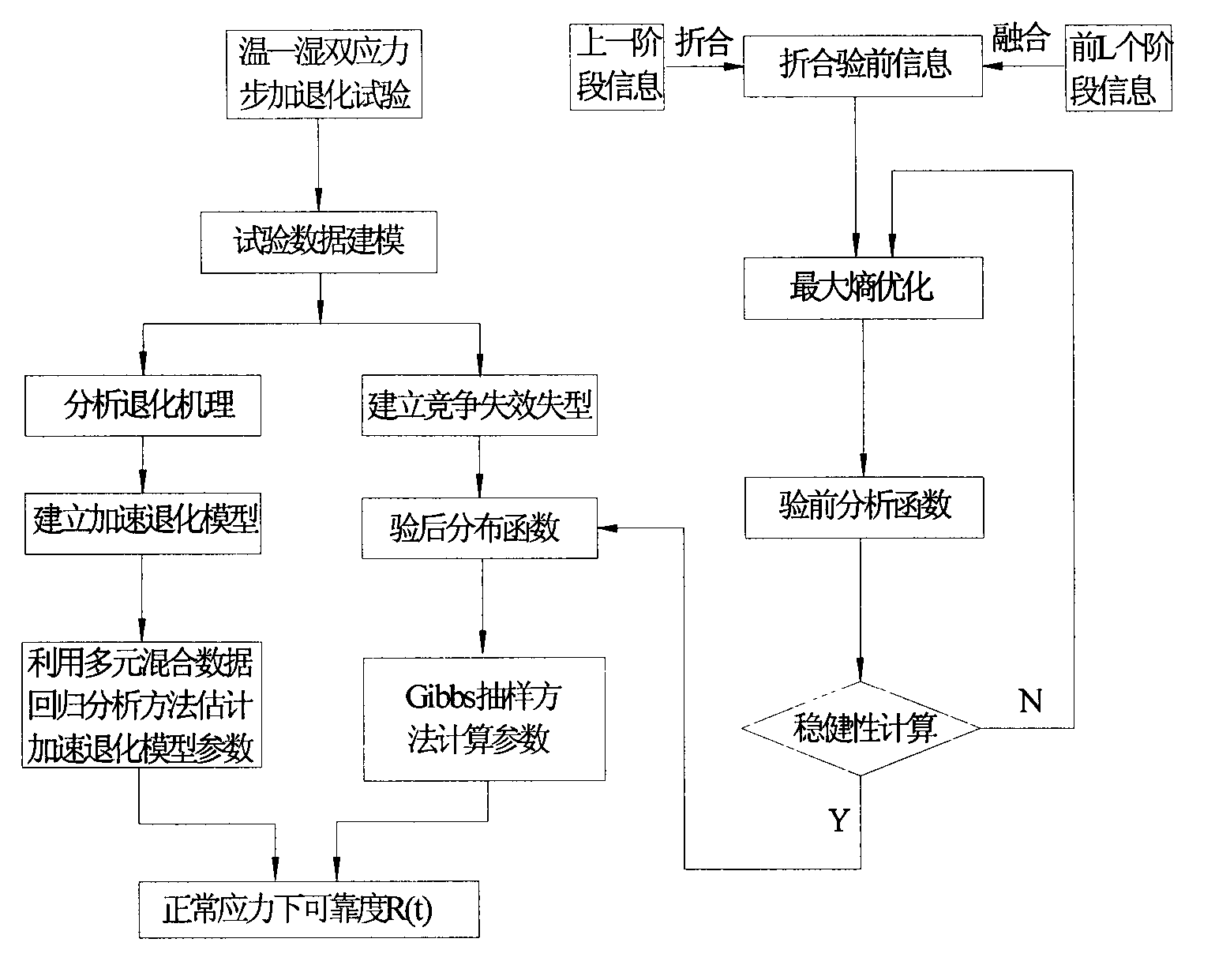

[0055] In conjunction with the accompanying drawings, the technical scheme adopted by the rapid Bayesian evaluation system for the reliability of the numerical control system under the degradation test proposed by the present invention mainly includes the following steps:

[0056] 1 CNC system double stress step test

[0057] Based on the previous FMECA analysis, it can be seen that temperature and humidity are the main environmental factors affecting the reliability of the CNC system. Therefore, it is proposed to use the temperature-humidity dual stress to carry out the double stress step test on the numerical control system. In order to further shorten the test time and realize the rapid evaluation of the reliability of the CNC system, regarding the temperature-humidity dual stress design problem in the step-accelerated life test, according to the proposed criteria and methods for the optimal design of the accelerated life test program, the CNC system is tested at the normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com