Static force load testing device for concrete beam

A technology for concrete beams and test devices, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of inconvenient movement, low utilization rate, large test error, etc., and achieves the effect of quick installation and disassembly, and easy storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

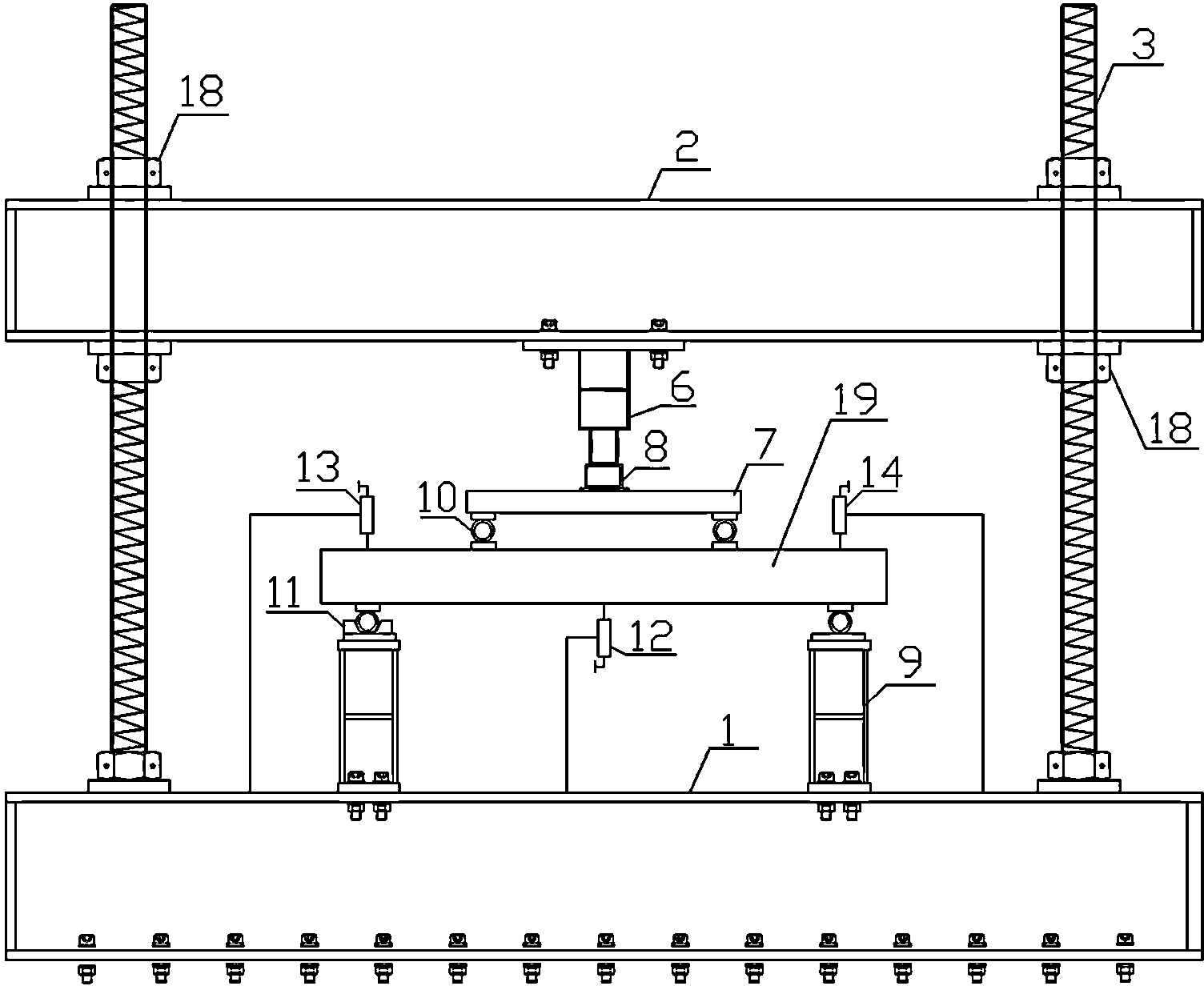

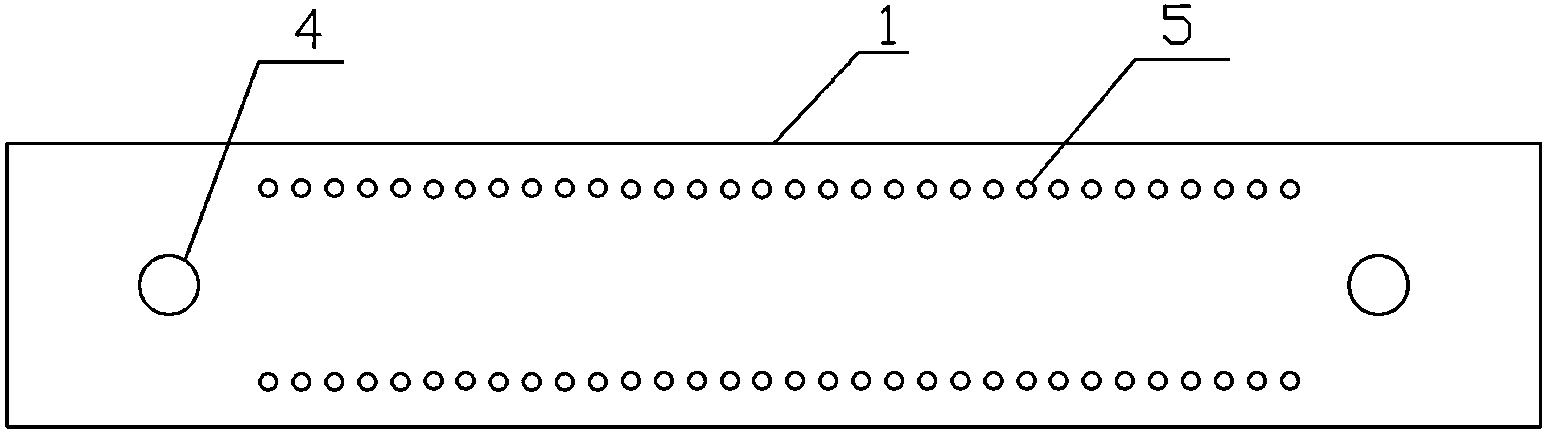

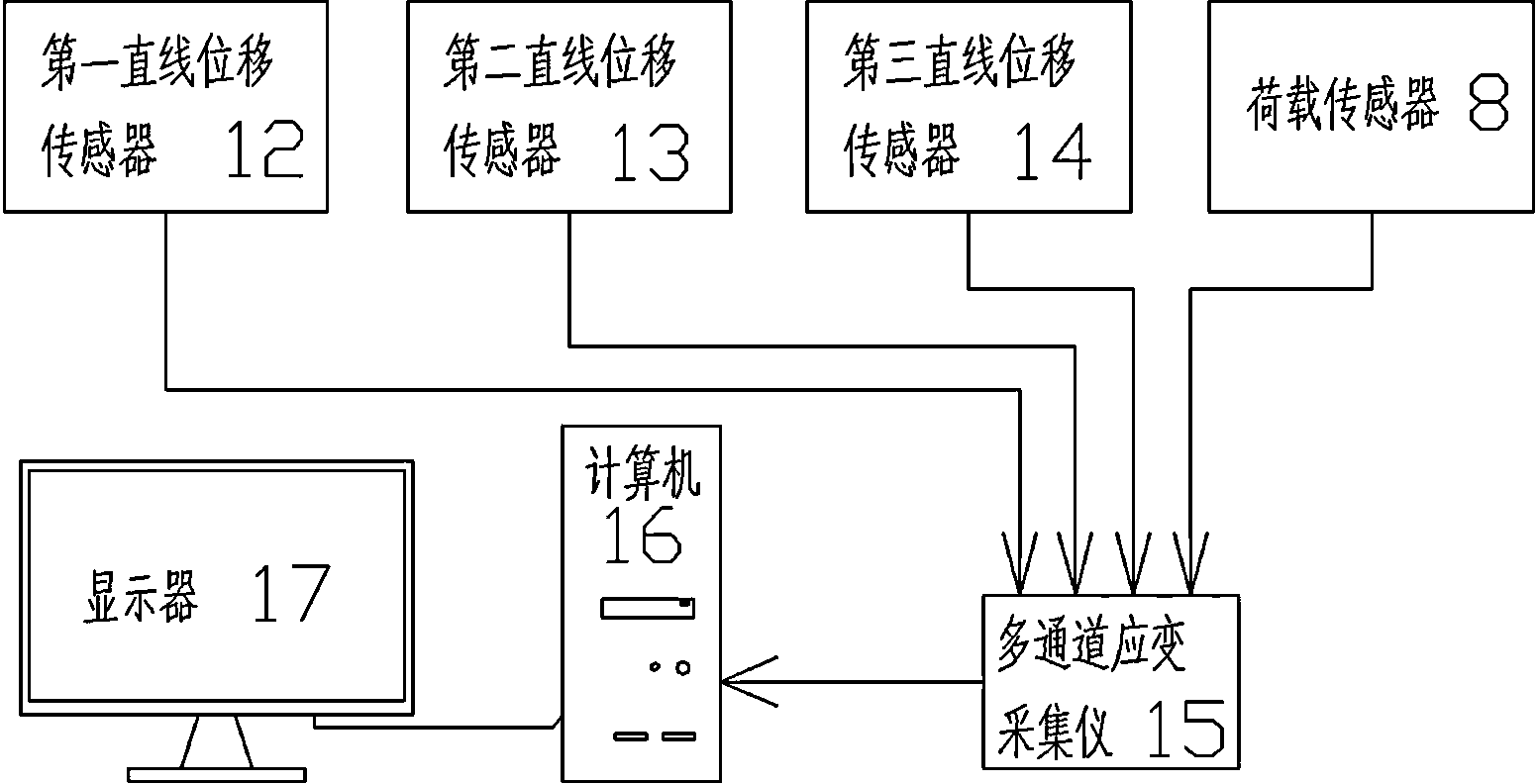

[0015] like figure 1 , figure 2 As shown, the concrete static loading test device provided by the present invention includes a base 1, a crossbeam 2, a column 3 fixedly connected to the base 1 and the crossbeam 2 on both sides of the base 1, and the two sides of the top of the base 1 are respectively provided with mounting holes 4, The column surface of the column 3 is provided with external threads, and the column 3 is fixedly connected with the base 1 through the mounting hole 4; the two sides of the beam 2 are provided with vertical through holes, and the column 3 passes through the through holes and is fixed to the beam 2 by nuts 18 Connection; the bottom surface of the beam 2 is installed with a hydraulic jack 6, a load sensor 8 and a load distribution beam 7 in sequence, and the two ends of the bottom surface of the load distribution beam 7 are respectively provided with a first ball joint 10 for transferring load to the concrete beam 19; on the base 1 There are two su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com