Test System for Pilot Load Control Valve

A technology of load control and test system, which is used in the testing of fluid pressure actuation systems, fluid pressure actuation devices, mechanical equipment, etc., and can solve the problems of testing the performance parameters of unloadable control valves, different test methods and systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

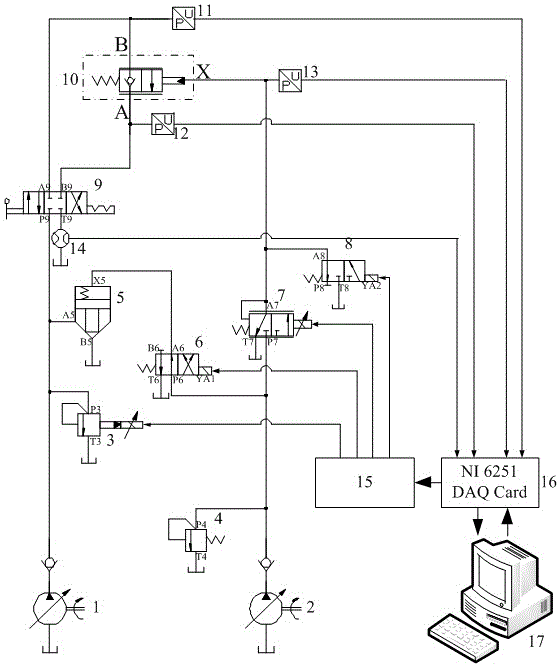

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

[0021] like figure 1 As shown, the present invention includes main oil circuit hydraulic pump 1, pilot oil circuit hydraulic pump 2, proportional relief valve 3, manual relief valve 4, pilot two-way cartridge valve 5, main oil circuit pilot reversing valve 6, proportional Pressure reducing valve 7, pilot oil circuit pilot reversing valve 8, manual directional valve 9, measured load control valve 10, load pressure transmitter 11, oil return pressure transmitter 12, control pressure transmitter 13, flow meter 14, a power amplification device 15, a data acquisition card 16 and a computer 17.

[0022] The oil outlet of the main oil circuit hydraulic pump 1 is connected to the pressure oil port P9 of the manual directional valve 9, and the oil inlet P3 of the proportional relief valve 3 and the oil inlet A5 of the pilot two-way cartridge valve 5 are connected by bypass. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com