Directional sound wave logging while drilling device

A sound wave, azimuth technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve problems such as incorrect measurement, and achieve the effect of reducing influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

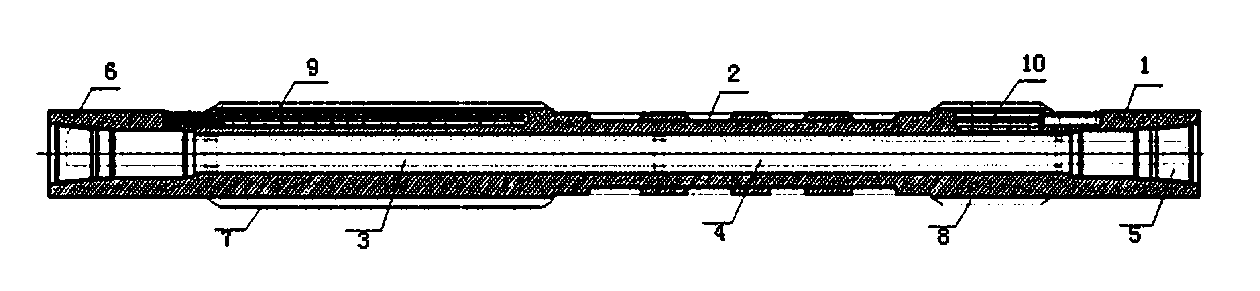

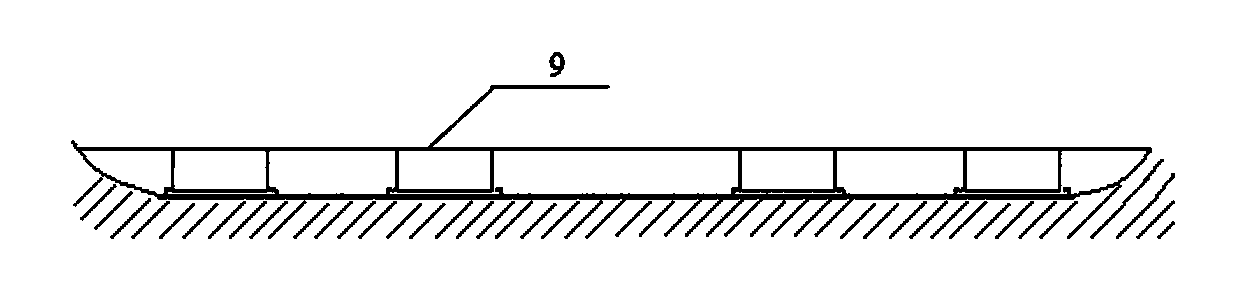

[0022] Such as figure 1 As shown, the azimuth acoustic logging device while drilling includes: special drill collar 1, acoustic system (transmitting probe 10, receiving probe array 9), measurement and control circuit 3, power supply battery 4 and upper and lower diversion sleeves 5, 6. The special drill collar 1 is a non-magnetic drill collar with an outer diameter of 178mm. The center of the special drill collar 1 is a mud flow channel. In order to install the acoustic system, centralizers 7 and 8 are designed during the processing of the special drill collar 1 to ensure sufficient The sound system is installed at the position, and the sound system is placed through the slot on the side wall of the centralizer. The sound system communicates with the upper end measurement while drilling system MWD (Measurement While Drilling) through the upper and lower guide sleeves 5 and 6 respectively, and is connected with the power supply battery 4 and the measurement and control circuit. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com