Construction method for hoisting heavy type ultrahigh steel member

A construction method and technology for steel components, which are applied in building construction, erection/assembly of bridges, and processing of building materials, etc., can solve the construction difficulties of hoisting heavy steel components, and the difficulty of entering large machines and tools, and achieve firm and reliable fixation. Safe and reliable, short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The hoisting construction method of heavy ultra-high steel component of the present invention includes the following steps:

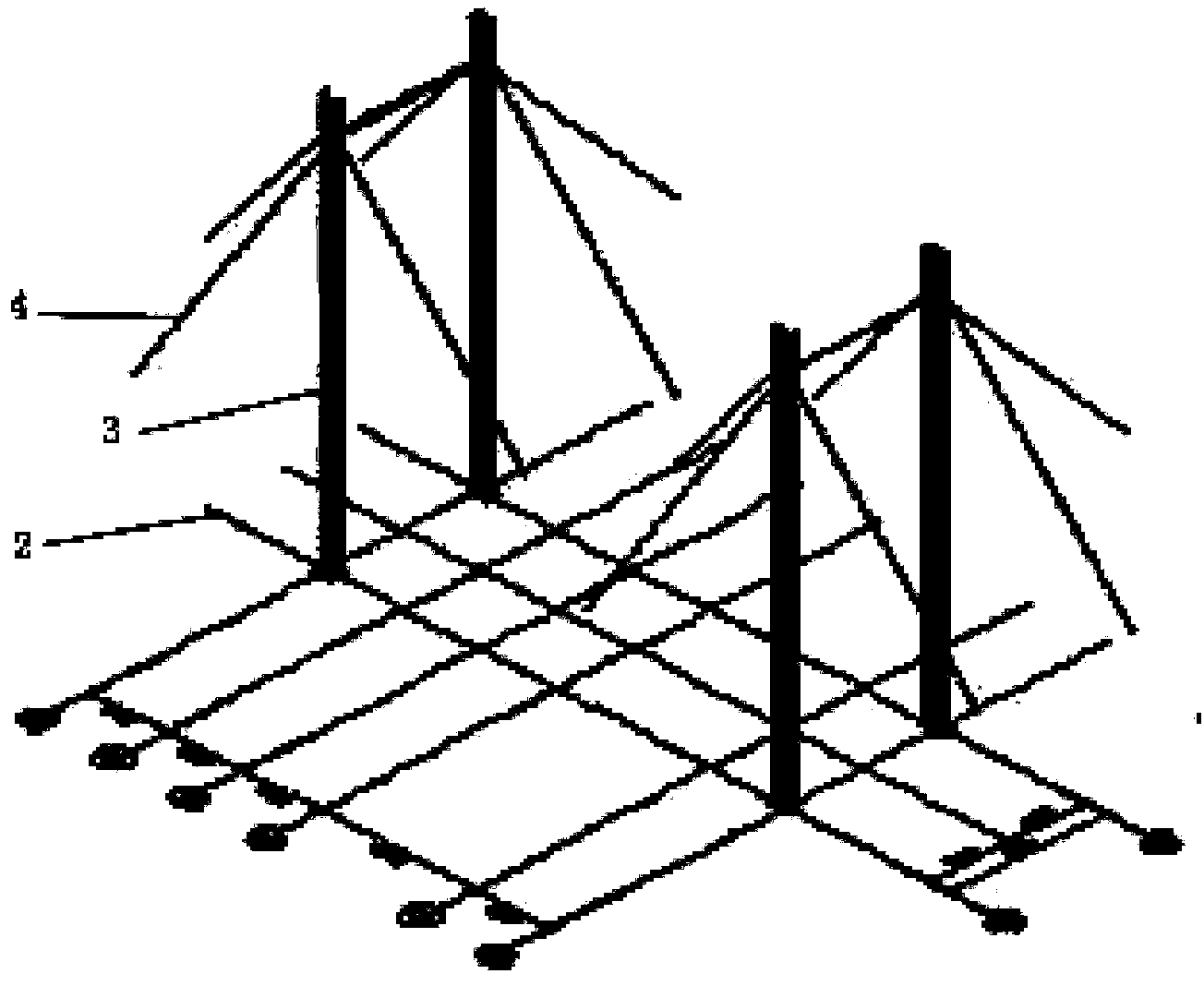

[0019] a. Component lofting: the steel structure refinement software is used to carry out the overall deepening design of the steel structure, and the beam-column connection node adopts the arc plate to strengthen all welding;

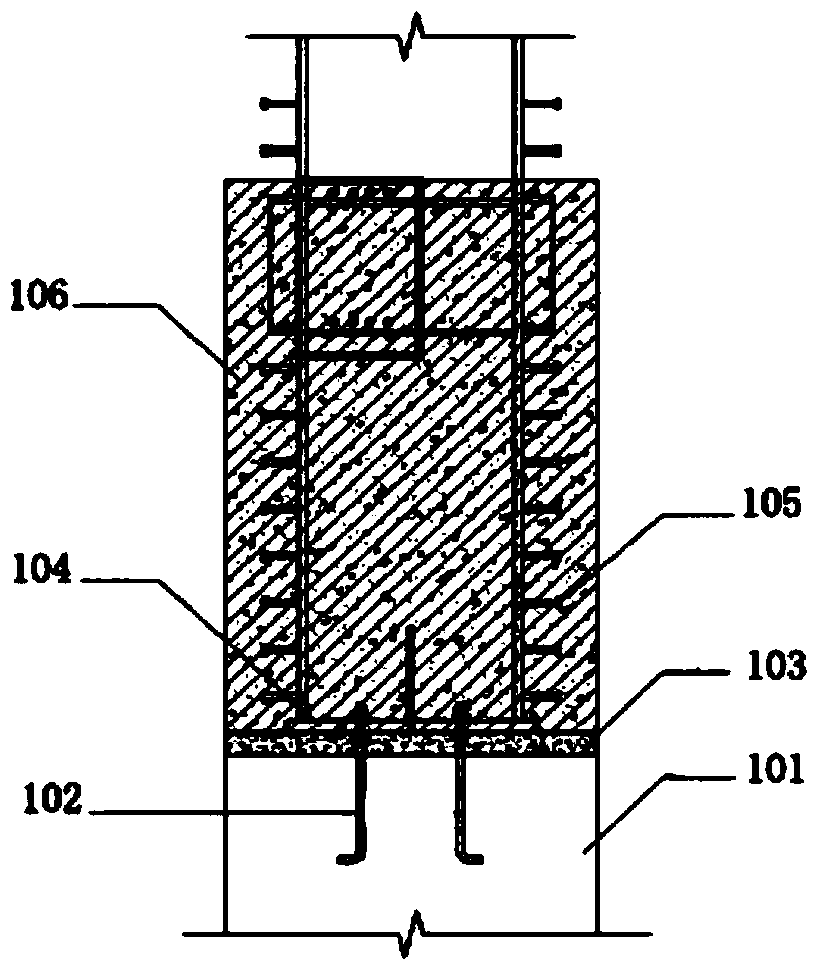

[0020] b. Pre-buried anchor bolts: Use angle steel to fix the anchor bolts as a whole, bind the fixing bracket and the bottom plate steel bar, add rigid supports around the fixed bracket, and then weld the anchor bolts and the bottom plate steel bar into a whole;

[0021] c. Hoisting the steel column: use a crane to lift the steel column using the single-machine rotation method. After the steel column is hoisted in place, insert the anchor bolt on the steel column bottom plate, place it on the adjusted nut, and place the steel column The center line of the four sides is aligned with the center line of the foundation line. When t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com