Weather-resistant water-based adhesive and preparation method thereof

An adhesive and weather resistance technology, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, polymer adhesive additives, etc., can solve the problem of low bonding strength, low free formaldehyde content, heat In order to improve the bonding strength and water resistance, improve the water resistance and environmental protection performance, and improve the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

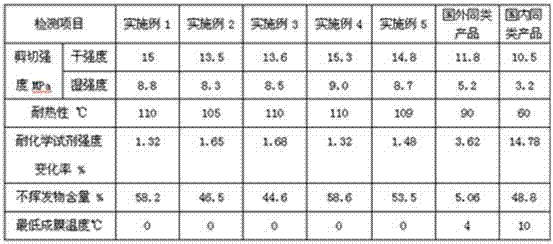

Examples

Embodiment 1

[0039] (1) Weigh each component according to the following weight ratio:

[0040] Deionized water 40%

[0041] Sodium acetate 0.01%

[0042] Disodium hydrogen phosphate dodecahydrate 0.05%

[0043] Protective colloid polyvinyl alcohol RS-2117 5%

[0044] Tartaric acid 0.3%

[0045] Cross-linking agent FeSO 4 0.003%

[0046] Vinyl acetate 52.972%

[0047] Cross-linking monomer styrene 0.005%

[0048] Hydrogen peroxide 0.1%

[0049] Antifungal agent Bactericidal preservative Huake-983 0.05%

[0050] Defoamer water-based defoamer Defom W-052 0.01%

[0051] Coalescent 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 1.5%;

[0052] (2) The weighed cross-linking agent FeSO 4Prepare the cross-linking agent FeSO with a mass concentration of 1% with deionized water 4 solution, ready to use;

[0053] (3) Add and prepare FeSO in the reactor 4 For the remaining deionized water after the solution, start stirring and add all sodium acetate, disodi...

Embodiment 2

[0058] (1) Weigh each component according to the following weight ratio:

[0059] Deionized water 52.638%

[0060] Sodium acetate 0.02%

[0061] Disodium hydrogen phosphate dodecahydrate 0.15%

[0062] Protective colloid polyvinyl alcohol RS-2117 3%

[0063] Tartaric acid 0.3%

[0064] Cross-linking agent FeSO 4 0.005%

[0065] Vinyl acetate 40%

[0066] Cross-linking monomer styrene 0.007%

[0067] Hydrogen peroxide 0.2%

[0068] Antifungal agent Bactericidal preservative Promex CHS4 0.15%

[0069] Defoamer water-based defoamer DEFOMEX 2063 0.03%

[0070] Coalescing agent diethylene glycol dibenzoate 3.5%;

[0071] (2) The weighed cross-linking agent FeSO 4 Prepare the cross-linking agent FeSO with a mass concentration of 1% with deionized water 4 solution, ready to use;

[0072] (3) Add and prepare FeSO in the reactor 4 For the remaining deionized water after the solution, turn on the machine and stir to add all the sodium acetate...

Embodiment 3

[0077] (1) Weigh each component according to the following weight ratio:

[0078] Deionized water 55%

[0079] Sodium acetate 0.01%

[0080] Disodium hydrogen phosphate dodecahydrate 0.05%

[0081] Protective colloid polyvinyl alcohol RS-2117 3%

[0082] Tartaric acid 0.15%

[0083] Cross-linking agent FeSO 4 0.003%

[0084] Vinyl acetate 40.122%

[0085] Cross-linking monomer styrene 0.005%

[0086] Hydrogen peroxide 0.1%

[0087] Antifungal agent Bactericidal preservative Promex CHS4 0.05%

[0088] Defoamer water-based defoamer DEFOMEX 2063 0.01%

[0089] Coalescing agent diethylene glycol dibenzoate 1.5%;

[0090] (2) The weighed cross-linking agent FeSO 4 Prepare the cross-linking agent FeSO with a mass concentration of 1% with deionized water 4 solution, ready to use;

[0091] (3) Add and prepare FeSO in the reactor 4 For the remaining deionized water after the solution, turn on the machine and stir to add all the sodium acetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com