Caterpillar movable hydraulic automatic setting machine

A mobile, brick stacking machine technology, applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of long brick clamping cycle, high labor cost, complex mechanism, etc., to reduce labor costs, Simple structure and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

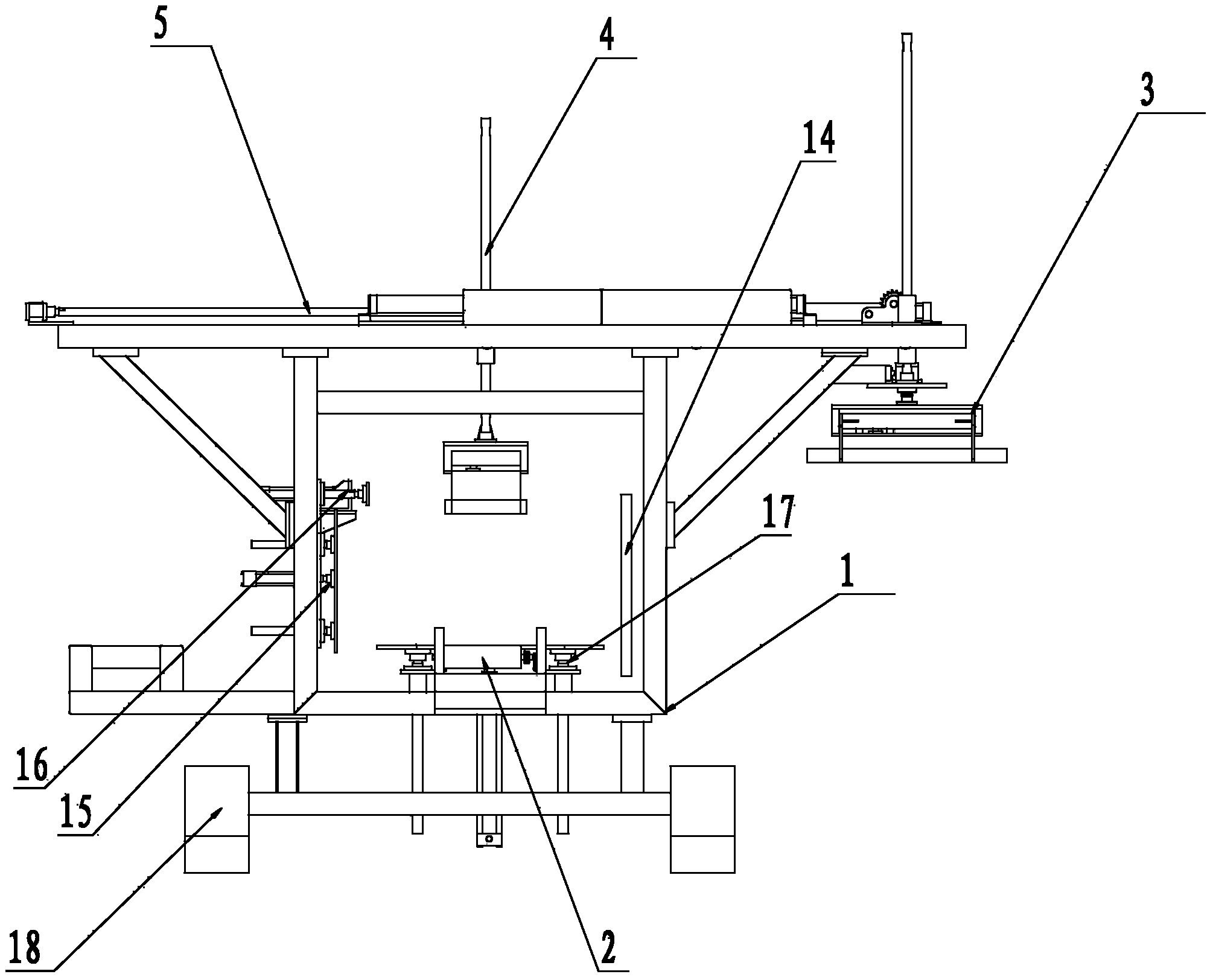

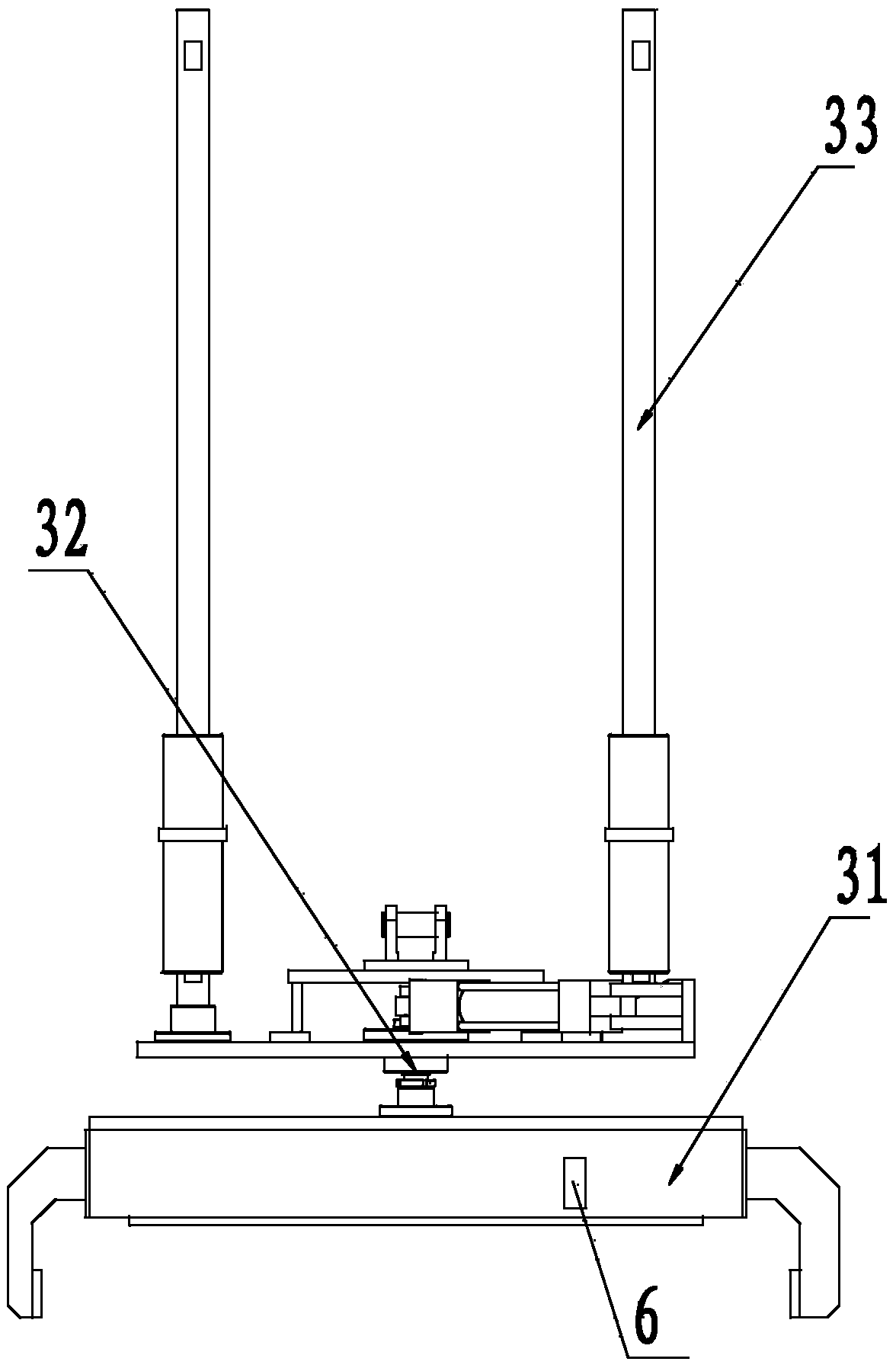

[0030] The present invention relates to a crawler mobile hydraulic automatic brick stacking machine, which comprises a supporting frame body 1 and a feeding mechanism 2 located on the supporting frame body 1, and a main clamping mechanism 3 for clamping bricks and The secondary clamping mechanism 4 used for the splint, the main clamping mechanism 3 and the secondary clamping mechanism 4 are movably connected with the supporting frame body 1 through the trolley running device 5 on the supporting frame body 1 .

[0031] In the present invention, the main clamp mechanism 3 includes a main clamp 301, a main clamp rotating mechanism 302 and a main clamp guiding device 303 for guiding the main clamp 301 and the main clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com