Device for filling containers

A technology of equipment, containers, applied in the field of equipment for filling containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

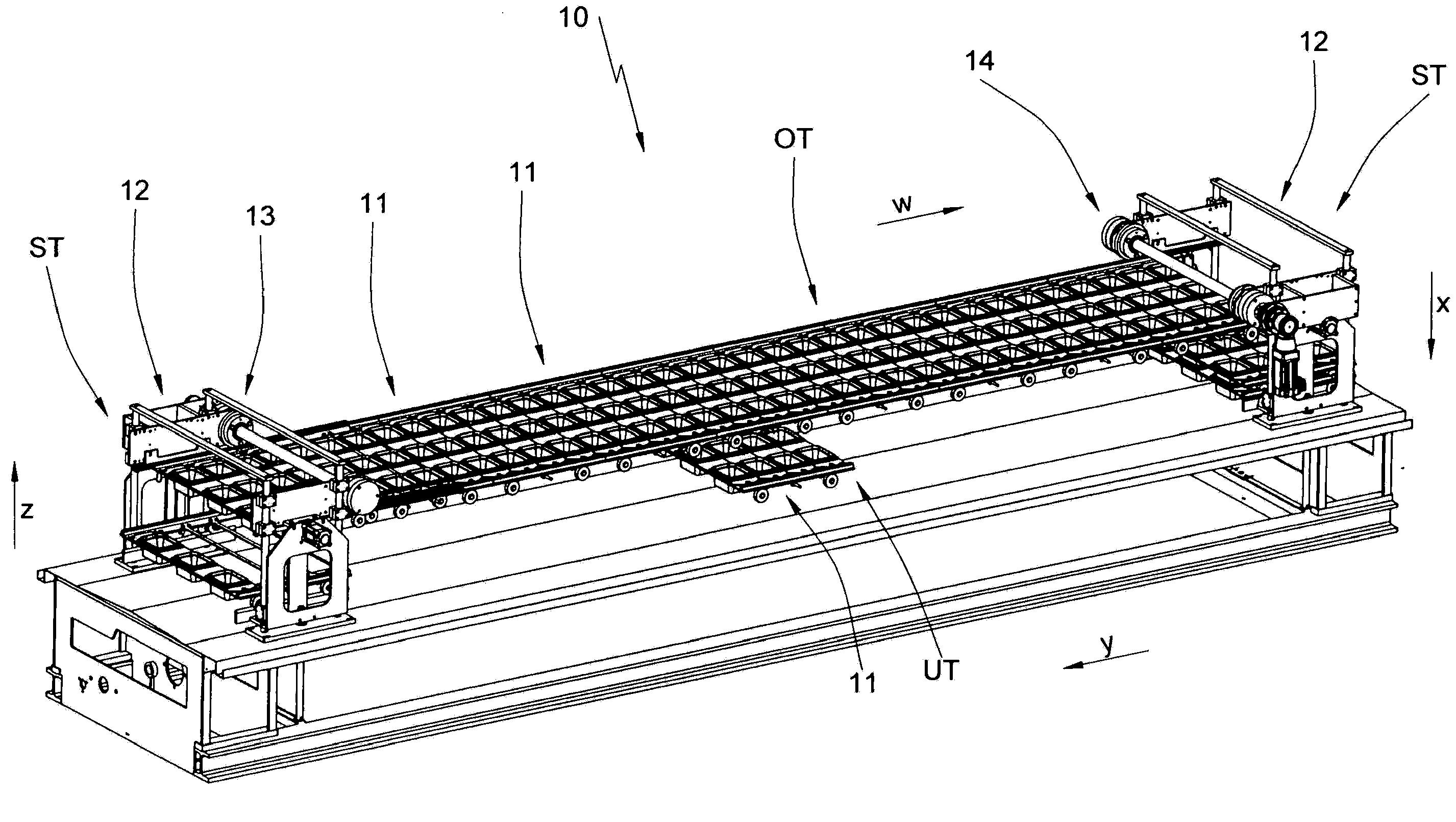

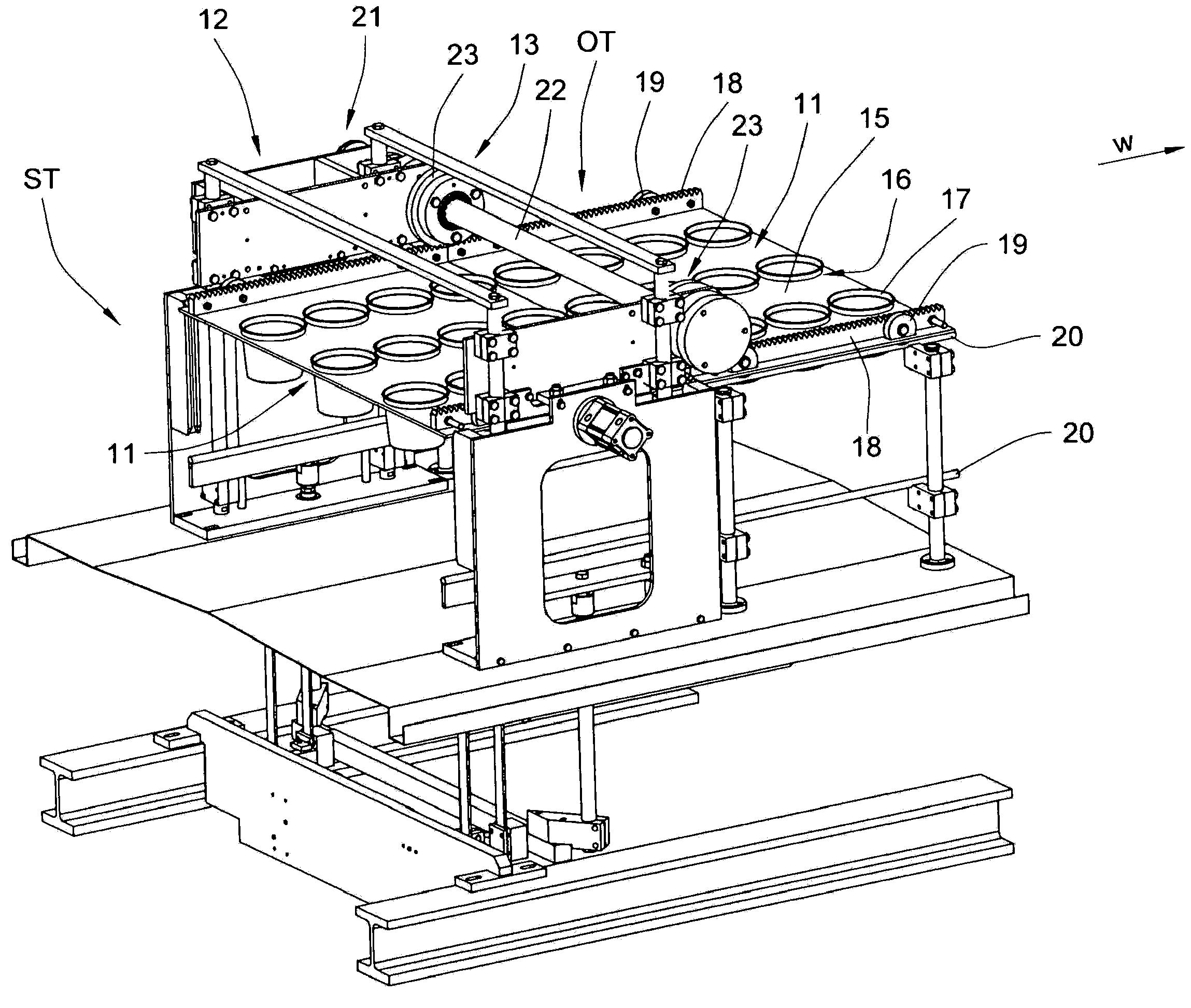

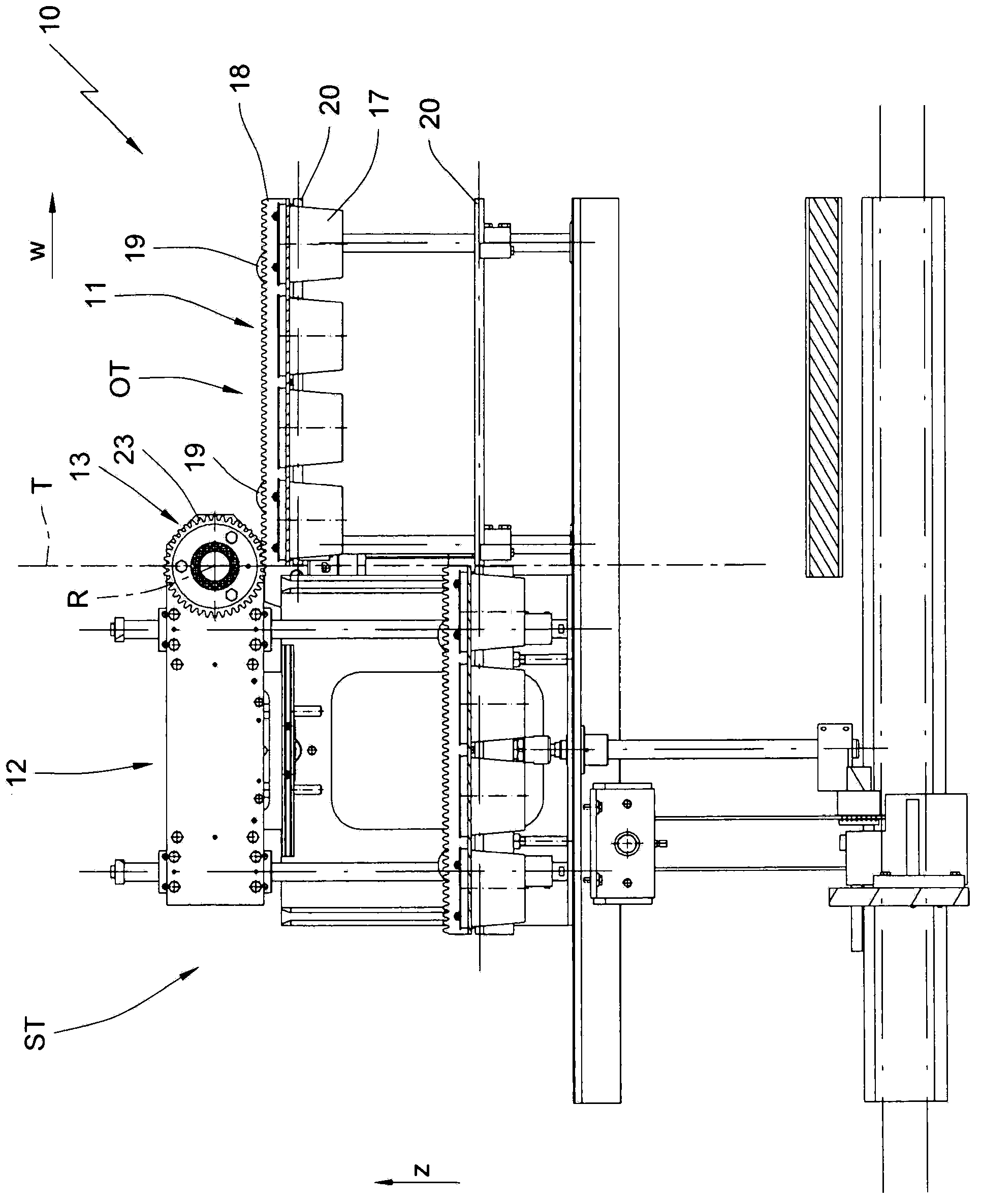

[0032] The device according to the invention is generally indicated with the reference numeral 10 in the figures.

[0033] The device 10 is a filling device for liquid or pasty food products such as margarine, milk products or fruit juices.

[0034] With reference to the placement plane, the device 10 has a horizontal upper branch OT and a horizontal lower branch UT. The upper branch OT and the lower branch UT are subsequently also referred to as main branches. The upper branch OT and the lower branch UT are connected to one another via two side branches ST, which are currently designed as elevators.

[0035] Each individual carriage 11 is guided cyclically along the branches OT, UT and ST. The carriage 11 is moved vertically from the upper branch OT into the lower branch UT and back again by the elevator 12 constituting the side branch ST. It is shown in detail that each carriage arranged in the upper branch OT runs in the upper branch OT in the transport direction W from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com