Electronic-gyroscope-autostabilization trailing arm electric damping active suspension damping device

An electronic gyroscope and electric damping technology, which is applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of small shock absorbing movement stroke, occupying the space at the bottom of the axle, and many components, so as to achieve stable body and increase Attitude stability, the effect of suppressing body sway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

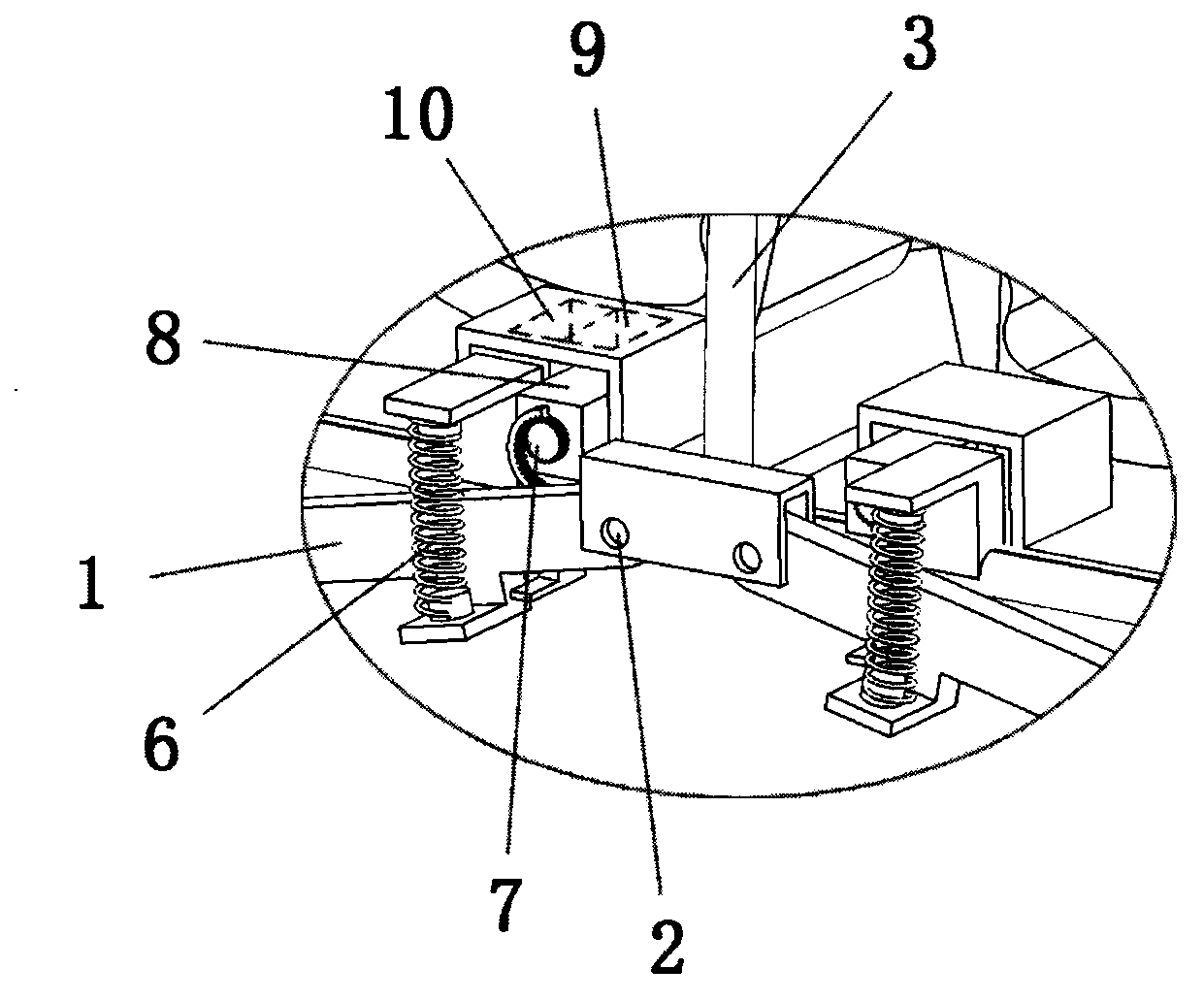

[0015] Such as figure 1 , figure 2 As shown, an electronic gyro stabilized trailing arm electric damping active suspension shock absorber includes a cantilever 1, one end of the cantilever 1 is fixed on the vehicle frame 3 through a bearing 2, and the other end is connected to the wheel 5 through a flange 4; A damping spring 6 is installed between the cantilever 1 and the frame 3, and the load of the frame 3 is transmitted to the cantilever 1 and the wheel 5 through the spring 6; during the shock-absorbing movement, the cantilever 1 swings up and down around the bearing 2 in a circle, and its circumferential plane Coincides with the direction of travel of the vehicle;

[0016] The transmission gear 7 is installed near the fixed end of the cantilever 1 and the vehicle frame 3 and connected to the damping motor 8 and the motor controller 9. The transmission gear 7 tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com