Special straightening machine for cold drawn stainless steel composite round tube

A compound round and straightening machine technology, applied in the field of cold-drawn steel pipe straightening, can solve the problems of difficulty in reaching the national standard for bending, low work efficiency, high labor intensity, etc., and achieves good wear resistance, good protection, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described in further detail below through the description of the best embodiment with reference to the accompanying drawings.

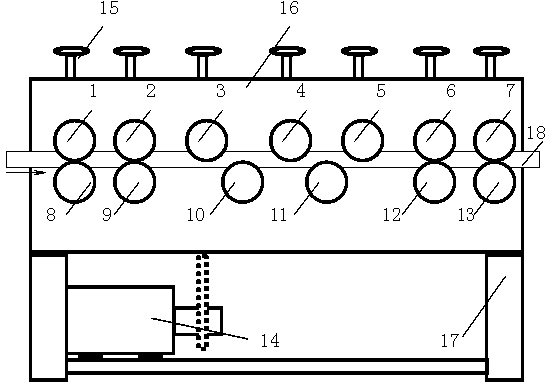

[0014] as attached figure 1 As shown, a special straightening machine for stainless steel composite round pipe is characterized in that it is composed of a transmission system 14, a body 16, a base 17 and a corresponding system of lead-in rollers, straightening rollers, and lead-out rollers.

[0015] According to the outer diameter of the stainless steel composite pipe to be straightened, install all the lead-in rollers, lead-out rollers and straightening rollers of the corresponding specifications, adjust the upper and lower and left and right optimal positions and reductions of the driving rollers listed above, and the stainless steel composite pipe to be straightened 18 It is introduced by two sets of lead-in rolls 1, 2, 8, and 9, repeatedly bent and corrected by straighteni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com