Application of a composite collector for beneficiation of fine-grained porphyry molybdenum ore

A composite collector and fine particle technology, applied in flotation, solid separation and other directions, can solve the problem of low utilization rate of porphyry-type fine-grained molybdenum ore resources, and achieve the goal of helping popularization and application, reducing dosage, selecting good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

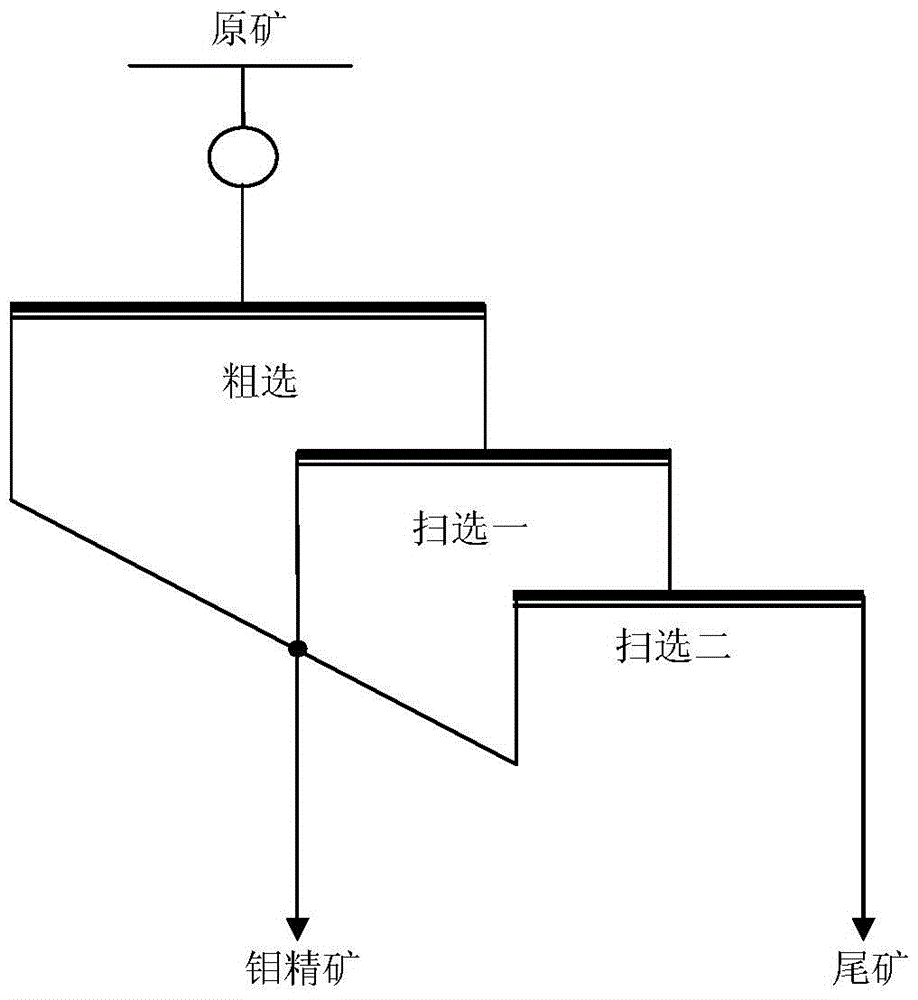

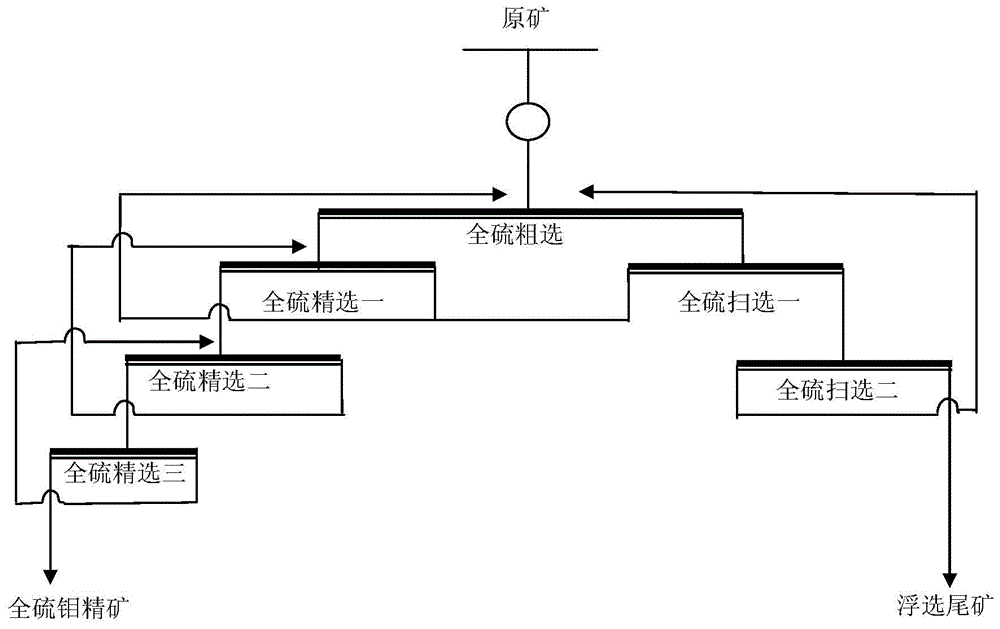

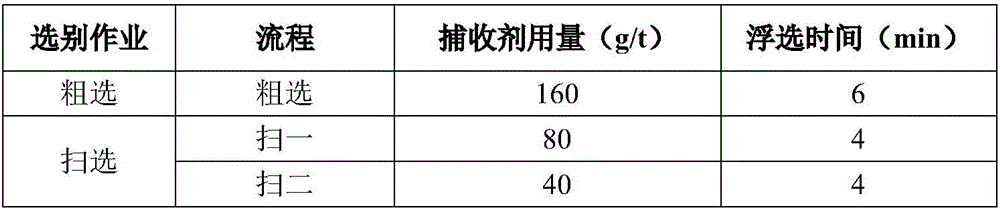

Method used

Image

Examples

Embodiment 1

[0021] The present embodiment is a composite collector for beneficiation of fine-grained porphyry molybdenum ore, which is composed of kerosene: butyl ammonium black medicine: ethyl disulfide: water=1: 0.075: 0.075: 100 by weight ratio.

Embodiment 2

[0023] In this embodiment, a kind of composite collector for beneficiation of fine-grained porphyry molybdenum ore is composed of kerosene: butyl ammonium black medicine: ethyl disulfide: water=1: 0.1: 0.1: 100.

Embodiment 3

[0025] In this embodiment, a kind of composite collector for beneficiation of fine-grained porphyry molybdenum ore is composed of kerosene: butyl ammonium black medicine: ethyl disulfide: water=1: 0.05: 0.1: 100.

[0026] After mixing the components in the above examples of the present invention, the homogeneous emulsion obtained by stirring with a mixer for 5 minutes is the composite collector of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com