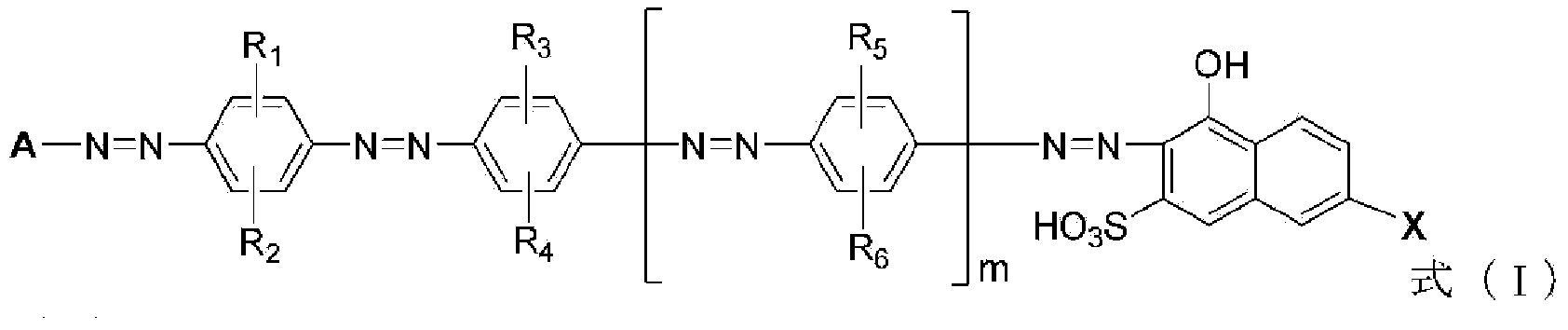

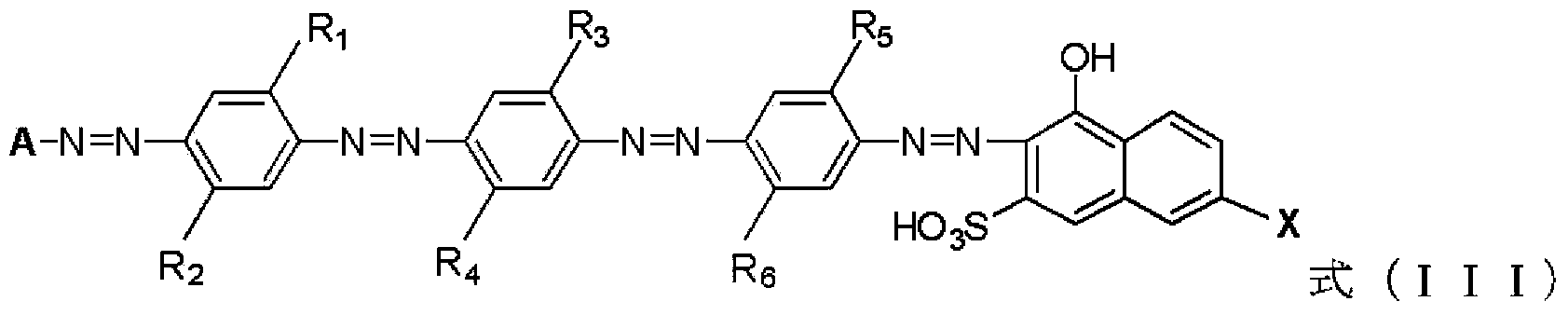

Polarizing element and polarizing plate

A technology of polarizing element and polarizing plate, applied in the field of dye-based polarizing element and polarizing plate, can solve the problems of low transmittance and low contrast of dye-based polarizing plate, and achieve the effect of improving optical properties and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0331] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited by these examples. In addition, the evaluation of the transmittance shown in an Example was performed as follows.

[0332] The respective transmittances were measured using a spectrophotometer ["U-4100" manufactured by Hitachi, Ltd.].

[0333] When the transmittance is measured using a spectrophotometer [manufactured by Hitachi, Ltd. "U-4100"], the transmittance after correction of the sensitivity based on JIS-Z8701 (C light source 2° field of view) is set on the light emitting side to 43 % and an iodine-based polarizer (SKN-18043P manufactured by Polatechno Co., Ltd.) with a polarization degree of 99.99%, so that absolutely polarized light can enter the measurement sample. The protective layer of the iodine-based polarizing plate at this time is triacetyl cellulose which does not have ultraviolet absorbing ability.

[0334] Absolutely polar...

Synthetic example 1

[0339] [Synthesis Example 1] Synthesis of Compound Example 12

[0340] Add 20.3 parts of 2-amino-5-methoxybenzenesulfonic acid to 500 parts of water, dissolve with sodium hydroxide, cool to below 10°C, add 32 parts of 35% hydrochloric acid, and then add 6.9 parts of sodium nitrite, Stir at 5°C to 10°C for 1 hour. Add 13.7 parts of 2,5-dimethylaniline dissolved in dilute hydrochloric acid water to it, while stirring at 30°C to 40°C, add sodium carbonate to make the pH to 3, further stir to complete the coupling reaction, and filter , to obtain monoazo compounds. To the obtained monoazo compound were added 32 parts of 35% hydrochloric acid, and then 6.9 parts of sodium nitrite, and stirred at 25°C to 30°C for 2 hours. Add 12.1 parts of 2,5-dimethylaniline dissolved in dilute hydrochloric acid water to it, while stirring at 20°C to 30°C, add sodium carbonate to make the pH to 3, further stir to complete the coupling reaction, and filter , to obtain diazo compounds. Disperse 1...

Synthetic example 2

[0341] [Synthesis Example 2] Synthesis of Compound Example 14

[0342] Change 6-(4′-aminobenzoyl)amino-3-sulfonic acid-1-naphthol (common name: aminobenzoyl J acid) in [Synthesis Example 1] to 6-(4′-benzoyl Except for acylphenyl) amino-3-sulfonic acid-1-naphthol (common name: benzoyl acid), it was synthesized in the same manner, and the trisazo compound shown in Compound Example 14 was obtained as a sodium salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com