Single-code-channel absolute position encoder

An absolute position and absolute technology, applied in the field of single-channel absolute position encoder, can solve the problem of difficult to achieve large-stroke measurement, achieve fast encoding and high-speed decoding, and solve the effect of limited measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

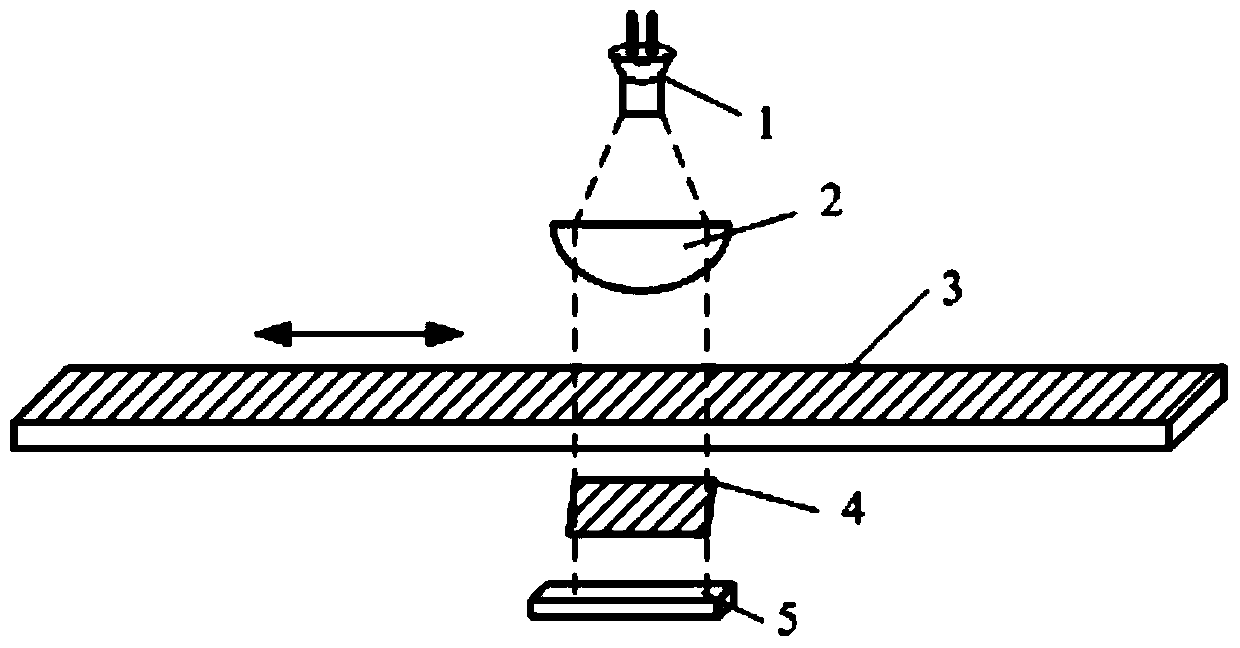

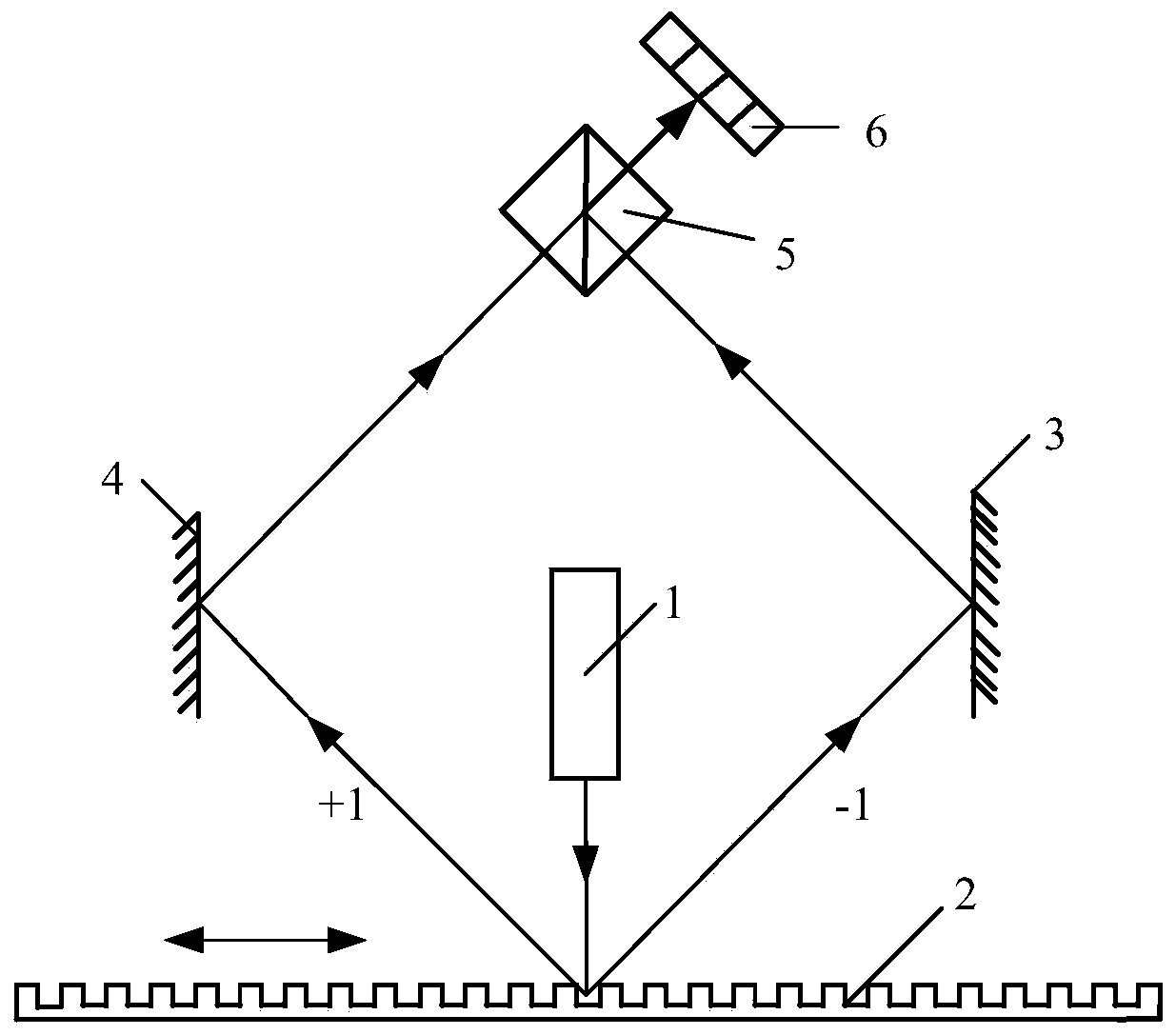

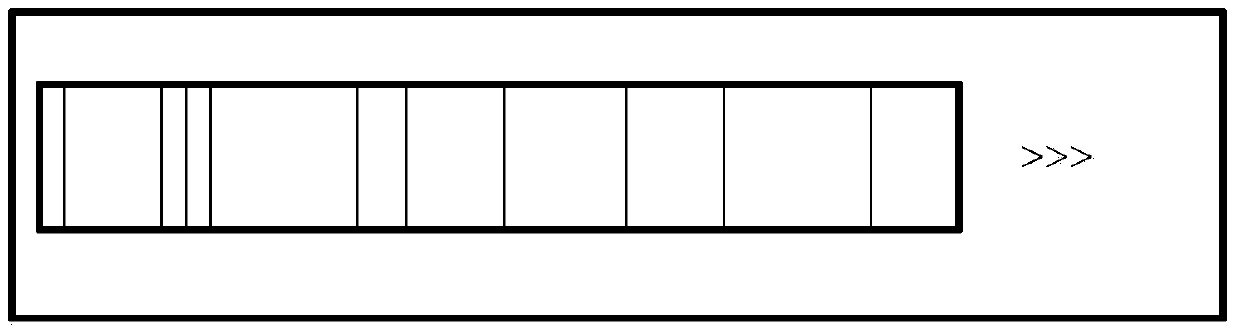

[0043] The principle of the single track absolute position encoder of the present invention is as follows: Figure 6 As shown, it includes two parts: reading system 1 and grating ruler 2. The reading system is composed of an illumination light source 4, a microscopic imaging lens group 5, a CCD photodetector 6 and a photoelectric signal processing module 7; The light beam emitted by the illumination source 4 irradiates the grating scale 2, and the CCD photodetector 6 obtains the coded image information of the engraved line on the coded track 3 through the microscopic imaging lens group 5, and finally obtains the grating displacement after passing through the photoelectric signal processing module 7. The photoelectric signal processing module 7 includes a driving module-identification code-position decoding algorithm.

[0044] The coding mode and the decoding algorithm implementation mode based on the M-ary coding algorithm of the present invention are as follows:

[0045] En...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com