A variable track pulley type ultrasonic ship lock sill wear detection device

A pulley cart and ultrasonic technology, applied in measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve complex problems that affect the safety and maintenance of ship locks, and difficult operations, so as to reduce the difficulty of manual operation and detection work Quantity, the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

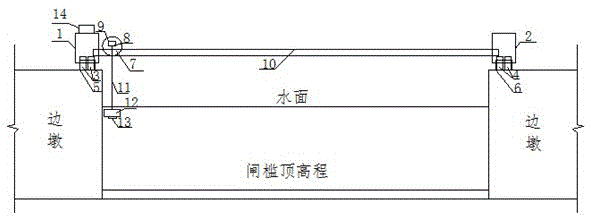

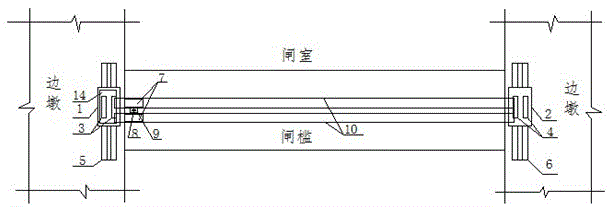

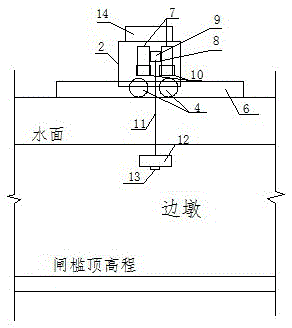

[0022] Below in conjunction with accompanying drawing, the implementation of technical scheme is described in further detail:

[0023] Such as image 3 As shown, the variable track pulley type ultrasonic ship lock sill wear detection device consists of a starting point fixed block 1, an end point fixed block 2, a starting point fixed block pulley device 3, an end point fixed block pulley device 4, a starting point track groove 5, and an end point track groove 6. Pulley 7, pulley intermediate connecting shaft 8, level device 9, pulley trolley track groove 10, boom 11, ultrasonic detection system 12, probe 13, control box 14, the control box includes system power supply, speed control system, Data acquisition system, data analysis system and output system, the control box 14 is 30×30cm in size, placed on the starting point fixed block 1, the starting point fixed block 1 and the end point fixed block 2 are solid steel blocks with a size of 50×30× 40cm, the starting point 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com