Packless sealing proportional valve

A proportional valve, tight technology, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of poor valve closing, poor flow adjustment effect, short service life, etc., to achieve convenient flow adjustment, tight closing, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

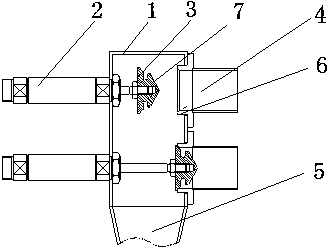

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] As shown in the figure, a non-tight sealing proportional valve is composed of a valve body 1, a valve stem 2 and a valve core 3. The valve body 1 is provided with a feed port 4 and a discharge port 5. The valve body 1 can be There is one material inlet and two material outlets, the material outlets are matched with the valve core, the valve body 1 can also be provided with two material inlets and one material outlet, the material inlets are matched with the valve core, to Applicable to different workplaces, the valve core 3 matches the feed port 4 and the discharge port 5 with a tapered surface, the feed port 4 or the discharge port 5 is provided with a sealing boss 6, and the inner hole of the boss 6 is set There is a tapered sealing ring surface, and the tapered sealing ring surface of the valve core is matched with the tapered sealing ring surface of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com