Concave cutterhead for large-diameter earth pressure balanced pipe-jacking machine of long-range jacking construction

A pipe jacking machine and earth pressure balance technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problem of not being able to meet the fast construction of super-long-distance super-distance pipe-jacking construction, insufficient strength and rigidity of the cutter head, and inability to cut Broken cement and soil and other problems, to achieve the effect of reasonable design and tool configuration selection and layout requirements, simple structure and high rigidity

Inactive Publication Date: 2014-04-30

SHANGHAI FOUND ENG GRP

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The present invention aims to solve the problem that the existing earth pressure balance pipe jacking machine has insufficient strength and rigidity of the cutter head, low cutter head opening rate, insufficient wear resistance, and inability to cut and break cement soil, etc., which cann

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

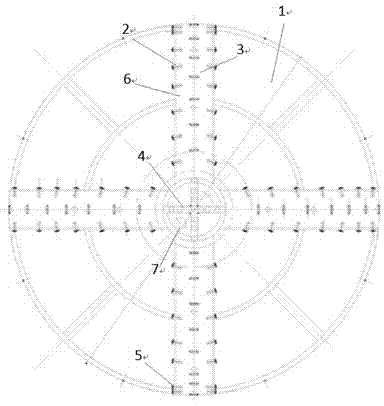

The invention relates to a concave cutterhead for large-diameter earth pressure balanced pipe-jacking machine of long-range jacking construction. The cutterhead comprises a cutterhead body in a spoke form. The center of the cutterhead body is provided with a support. Aperture ratio of the cutterhead body is high. The front of the cutterhead body is provided with cutting tools and advancing tools. The back of the cutterhead body is provided with mixing rods. The concave cutterhead is simple and solid in structure, high in strength and rigidity, high in wear resistance and long in service life, is rigid and strong enough to support a large-diameter excavation face and bear tunneling thrust and torque, has the effect of guaranteeing excavation diameter, is capable of breaking hard or harder rock layers and reinforcing zone cement and the like, and can meet the construction requirements for ultra-long-range pipe jacking in complex formations. A face plate of the spoked cutter head is large and the aperture ratio of the spoked cutterhead is high, so that smoothness of much entering an earth compartment is guaranteed and tool wear is reduced. The mixing rods provided have the effect of mixing earth in the earth compartment, so that earth cakes are avoided, the plasticity and fluidity of earth is improved, the earth is convenient to convey out of the earth compartment, unearthing speed is increased, and construction efficiency is improved.

Description

technical field [0001] The invention relates to an earth pressure balance pipe jacking machine cutterhead for building construction, in particular to a large diameter earth pressure balance pipe jacking machine capable of cutting and repeatedly breaking cement soil and rock and soil for long-distance jacking construction Concave cutterhead. Background technique [0002] At present, the existing earth pressure balance pipe jacking machine cutter head is used in the construction of the SST2.2 bid section of the eastern section of the Bailonggang sewage treatment south line project with an outer diameter of 4640mm and a single jacking length of 2039.82m. There will be certain limitations. The SST2.2 bid section of the eastern section of the Bailonggang sewage treatment south line project is currently the pipe jacking project with the largest diameter and the longest distance with the same diameter. The pipe jacking diameter is large and the distance is long, so it needs to hav...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21D9/08

Inventor 顾杨李耀良徐玉夏罗云峰张海锋王涛

Owner SHANGHAI FOUND ENG GRP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com