A plastic toilet body and its manufacturing method

A toilet and mother technology, which is applied in the field of bathroom, can solve the problems of low productivity, large product deformation, and it is difficult to meet the special requirements of bathroom layout at the same time, and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

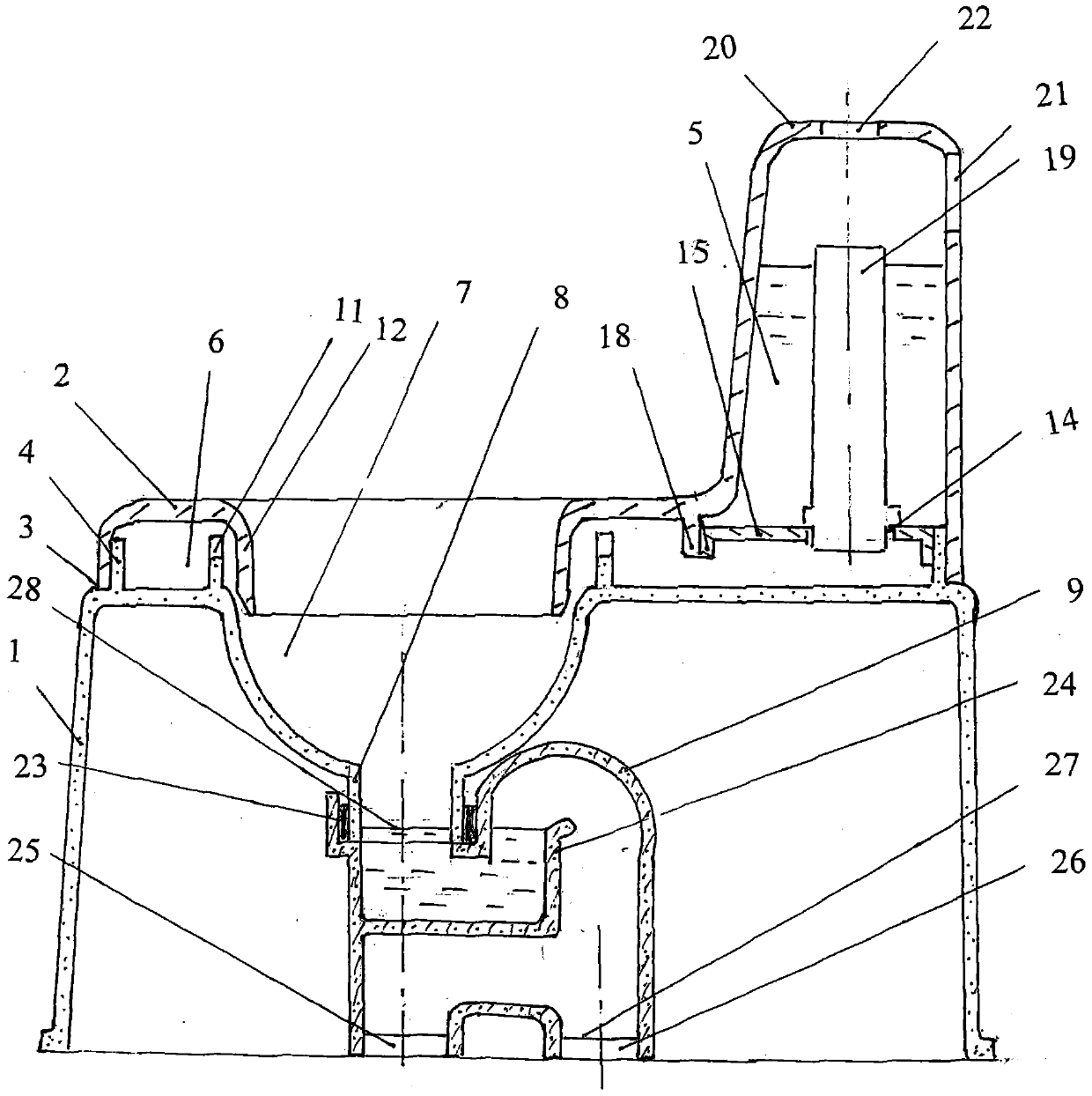

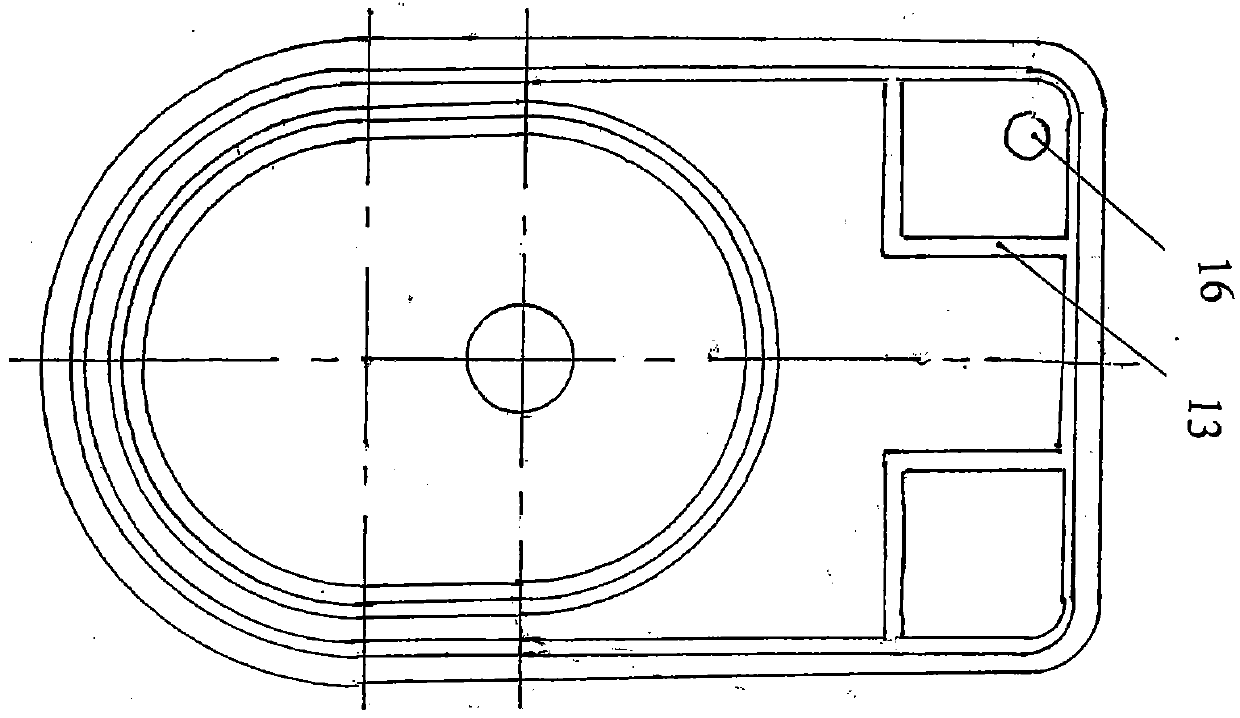

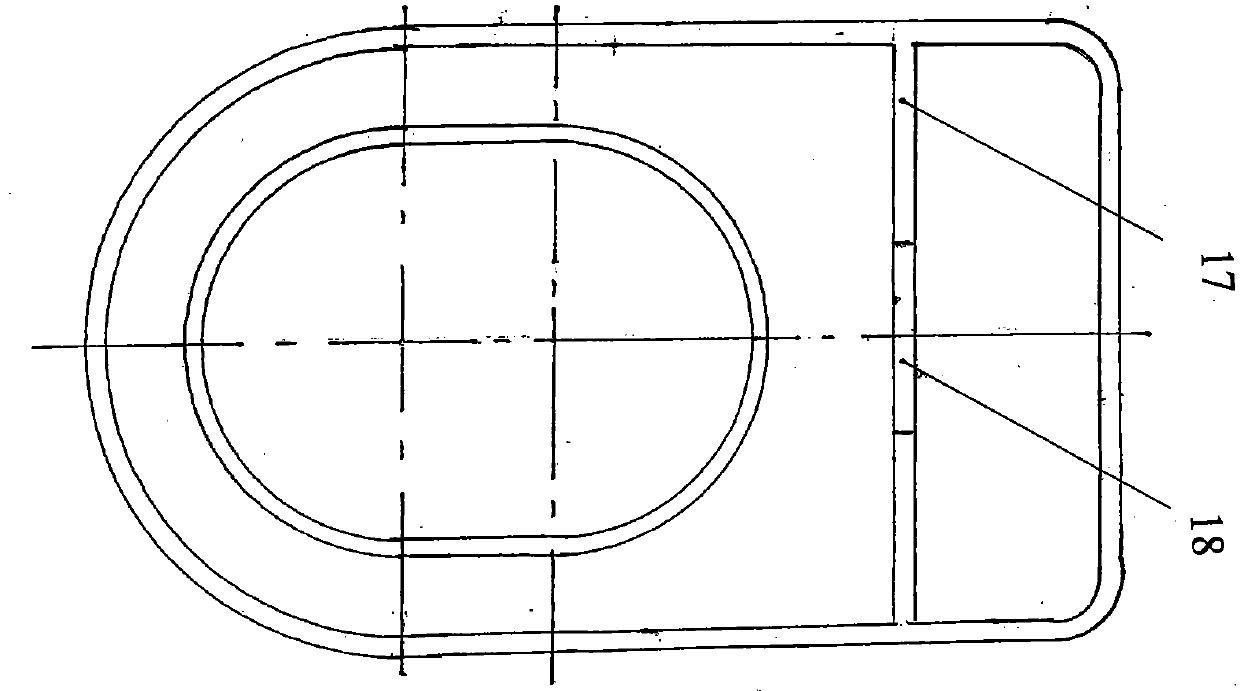

[0018] Refer to attached figure 1 The base (1) of the injection-molded toilet body and the upper cover (2) of the injection-molded toilet body are combined by bonding or welding to form the body of the toilet. Wherein the base of the toilet base (1) is designed to be slightly larger in size at the peripheral bottom which is in contact with the ground, and the size of the upper part of the periphery matched with the upper cover of the toilet base (2) is designed to be slightly smaller in size to form a draft slope so as to facilitate the base of the toilet base (1) Demoulding from the bottom during injection molding; the outer side of the upper plane (3) of the base of the toilet base (1) is slightly inwardly injection molded to form the outer side of the periphery of the continuous rib (4) and the upper cover of the toilet base (2) ) the inner side of the outer periphery of the lower part is bonded or hot-melted to form the outer sealing surface of the water tank (5) and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com