Method and device for aeration of pressed inlet of gentle slope open channel

An air device and open channel technology, which is applied in the field of air aeration and corrosion reduction, achieves the effects of good air aeration effect, increased air aeration concentration, and improved air aeration and corrosion reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

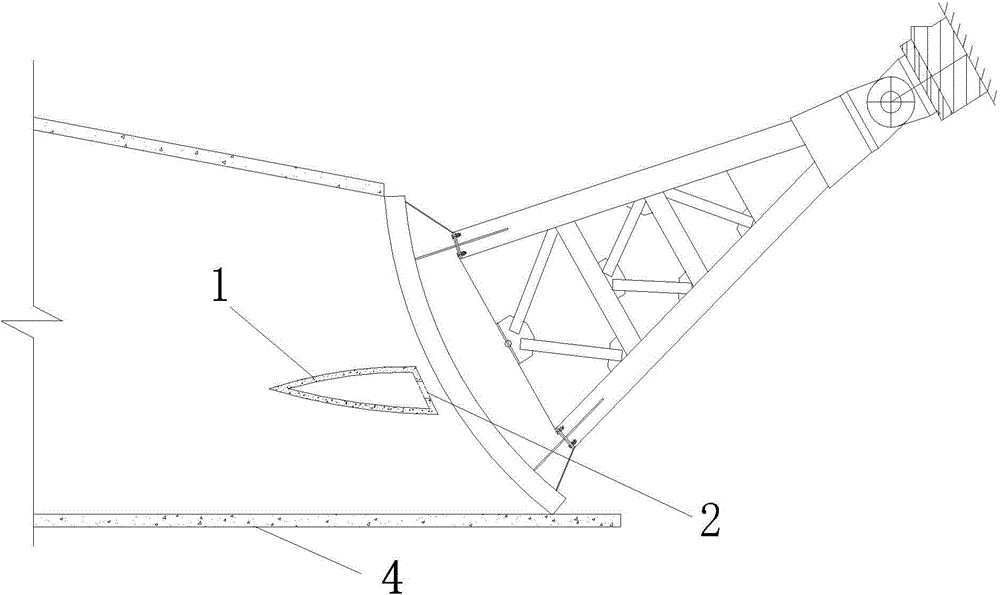

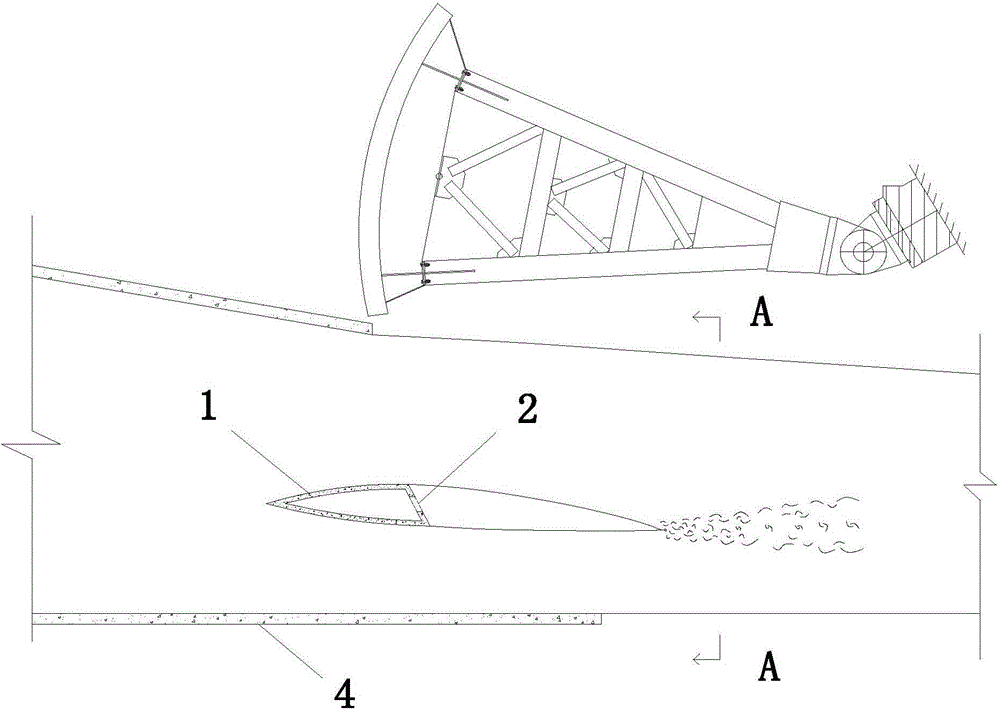

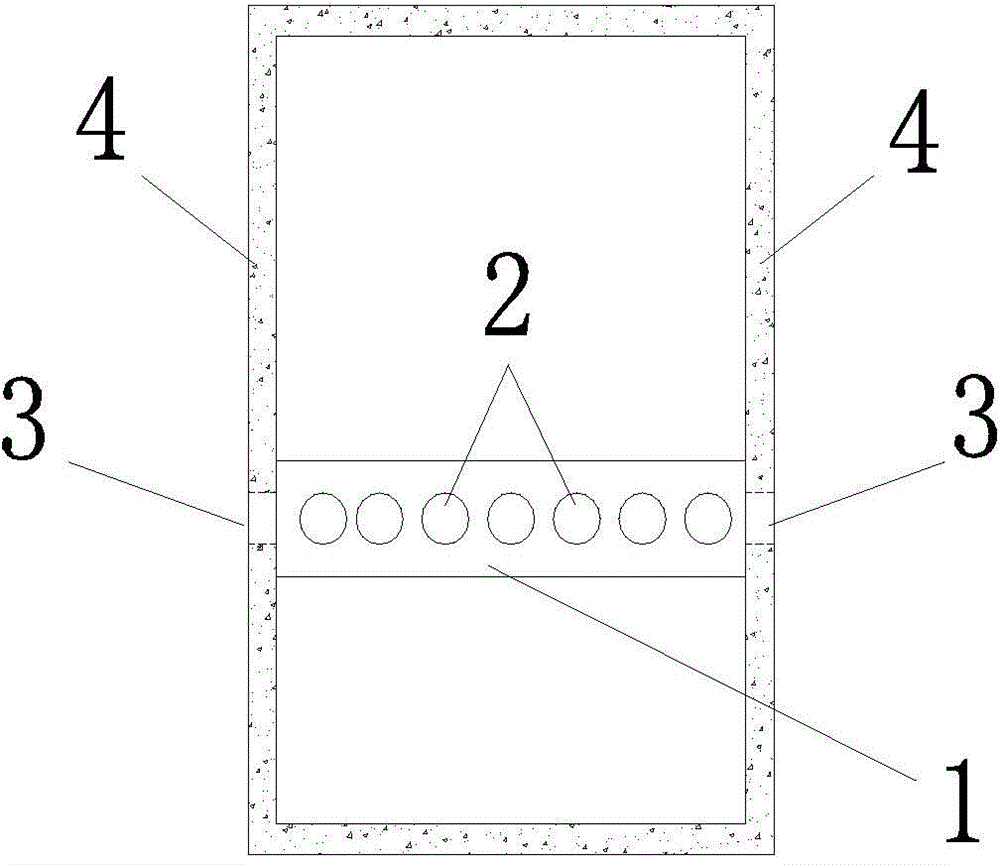

[0023] The structure of the gentle-slope open channel of this embodiment with the pressure inlet aeration device is as follows: figure 1 , 2 As shown in , 3 and 4, a wedge-shaped aerator 1 is set at the end of the pressure inlet of the gentle slope open channel at a distance of 0.5m from the bottom of the flow tunnel, and the height ratio of the water outlet below it to the water outlet above it is 1:1. The wedge-shaped aerator is a hollow wedge-shaped section structure, and is horizontally arranged on the holes 4 on both sides of the flow hole with the wedge end facing the direction of the incoming water flow and the bottom of the wedge facing the direction of the incoming water flow. The wedge-shaped walls on the upper and lower sides are streamlined curved surfaces. The two ends of the cavity of the aerator are designed with air inlet holes 3 to allow air to enter the cavity. There are a number of ventilation holes 2 distributed at the bottom of the wedge. 3. It communica...

Embodiment 2

[0025] The gentle slope open channel of this embodiment has a pressure inlet aeration device, and its structure is basically the same as that of Embodiment 1, the difference is that the wedge-shaped aerator 1 is arranged at 1.0m away from the bottom of the overflow tunnel, below the wedge-shaped aerator. The ratio of the height of the water outflow outlet to the height of the water outflow outlet above is 1:4. The air intake holes 3 located at both ends of the cavity of the aerator communicate with the atmosphere through the tube holes located in the walls of the cavity on both sides of the flow tunnel, and the air inlet is higher than the water surface of the reservoir area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com