Device used for carbon fiber surface modification

A surface modification, carbon fiber technology, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of uneven oxidation, reduced performance of composite materials, poor oxidation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

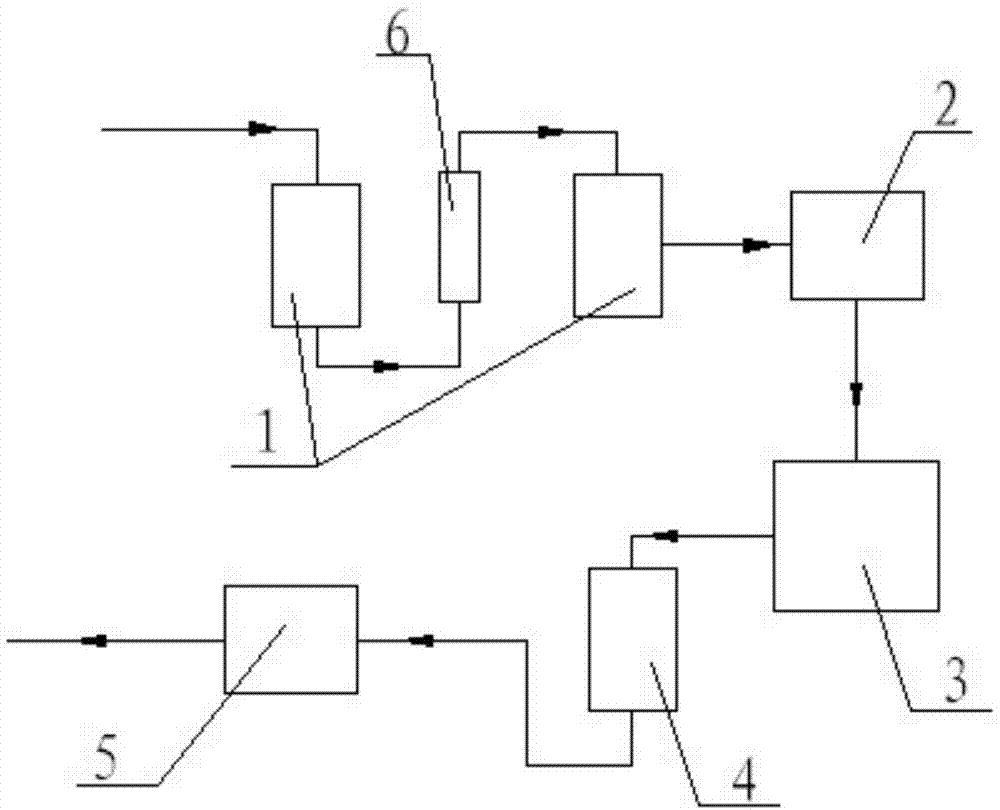

[0011] Such as figure 1 Shown, a kind of device that is used for carbon fiber surface modification, comprises successively connected two-stage epoxy resin bath device 1, oxidation treatment device 2, carbon fiber surface washing device 3 and drying device 5, described two-stage epoxy resin bath A carbon fiber surface brushing device 6 is arranged between the devices 1, the oxidation treatment device is a high-temperature reaction kettle, an epoxy resin bath device 4 is arranged between the carbon fiber surface washing device 3 and the drying device 5, and the drying device 5 is Electric oven.

[0012] The working principle of the present invention is as follows:

[0013] (1) First put the carbon fiber bundles into the first-level e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com