A fine-tuning disc brake caliper

A brake caliper, a technology of a caliper, applied in the field of bicycle disc brake calipers, can solve the problems of brake pad quality wear, disc brake debugging difficulties, difficult to achieve, etc., to achieve good braking, fast and stable loading and debugging, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

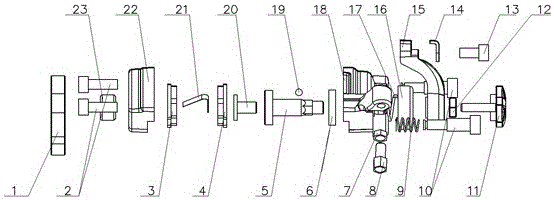

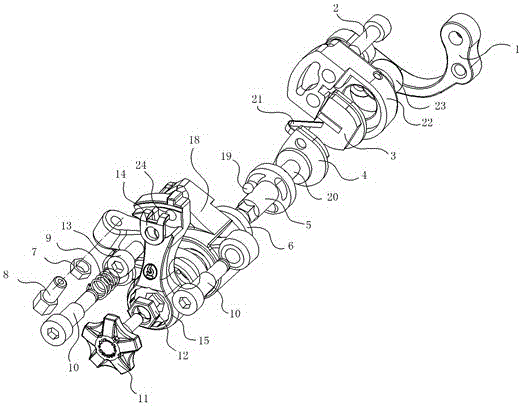

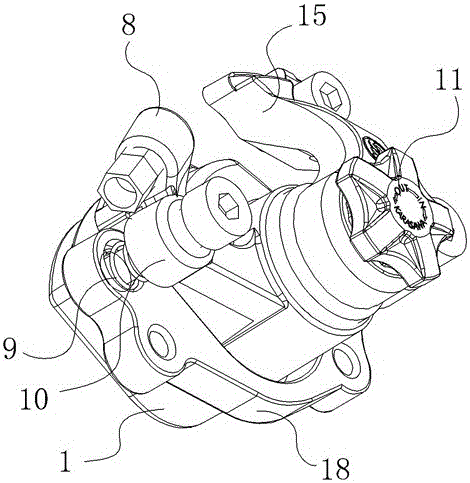

[0018] Such as Figure 1-3 As shown, a fine-tuning disc brake caliper, which includes:

[0019] A caliper main body 18, the caliper main body 18 has a tight rope adjustment part and a support part, the tight rope adjustment part includes a tight rope adjustment nut 7 arranged on the caliper body 18, a tight rope adjustment screw 8 and a tight rope adjustment screw 8 arranged on the rocker arm 15 Rope screw plate 14, lock rope screw 13, described rocking arm 15 is provided with tight rope polygonal column hole 24, and described lock rope screw 13 is screwed tight rope screw plate 14 in the tight rope polygonal column hole 24, so The tightening rope adjusting nut 7 is screwed on the caliper main body 18 by the thread of the tightening rope adjusting screw 8

[0020] Both ends of the caliper main body 18 are provided with a fine-tuning device and a protective cover. The protective cover includes a cover plate 22 and a dust cover 16. The caliper main body 18 and the dust cover 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com