Flatting mill capable of automatically coiling material

A flattening machine and coiling technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of lowering its own temperature, unable to effectively complete the cooling, easy to sink quickly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

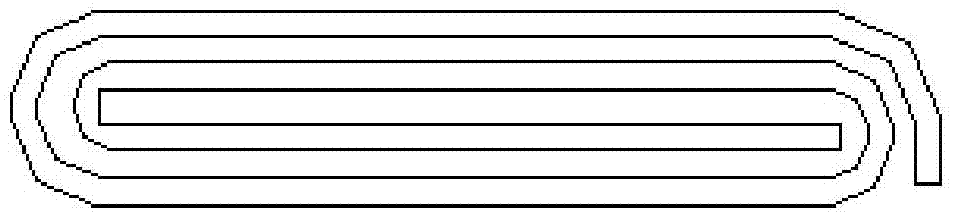

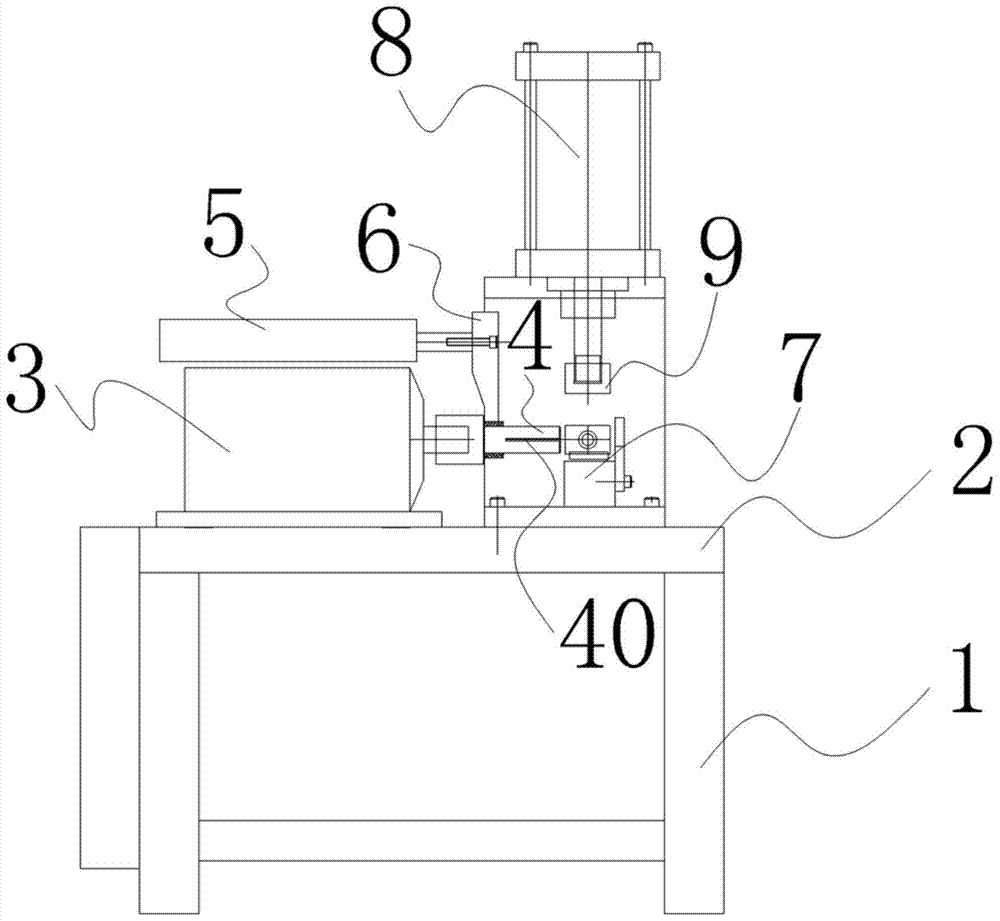

[0024] like Figure 3-4 As shown, the automatic roll material flattening machine has a bearing frame 1, a working surface 2 on the bearing frame, and a rotatable mechanism 3 installed on the bearing frame. Considering that the structure of the hand-operated shaft cannot meet the requirements of automation Requirements, here the rotatable mechanism adopts electronic equipment parts such as motors to facilitate the control of the intelligent control system. The rotating shaft of the motor as the rotatable mechanism is connected to a fixed shaft 4 with a radial slot 40, the slot It extends to the free end of the fixed shaft and the slot is arranged in a horizontal state. The notch of the slot is in a horizontal state to facilitate horizontal dockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com