Space serial rotary joint type teleoperated manipulator and its combination

A technology of rotary joints and teleoperation, applied in the direction of manipulators, claw arms, joints, etc., can solve problems such as no instructions or reports found, no data collected, etc., and achieve the effect of increasing speed and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

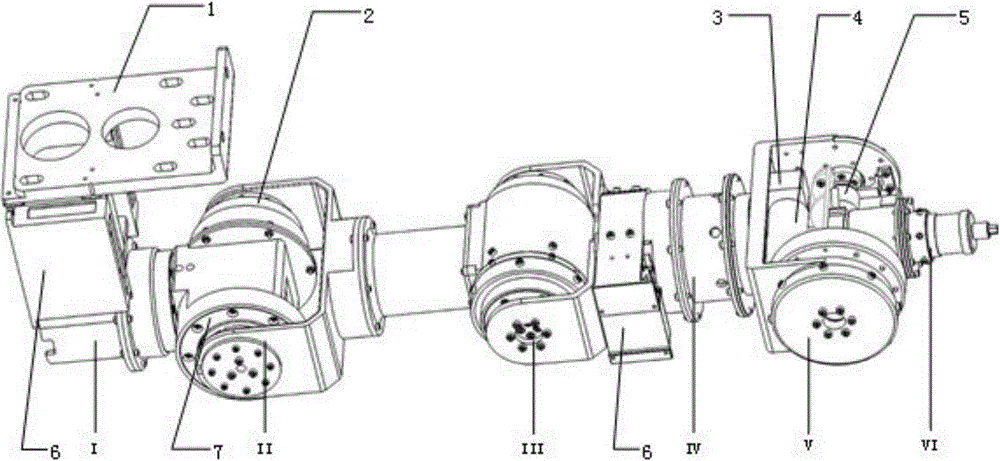

[0046] like figure 1 and figure 2 As shown, this embodiment provides a space series rotary joint teleoperated manipulator, including any one or more of the following joints:

[0047] - Turnover joint I;

[0048] - pitch joint II;

[0049] - pitch joint III;

[0050] -Front end turnover joint IV;

[0051] - middle pitch-rotation joint V;

[0052] - Terminal turnover joint VI.

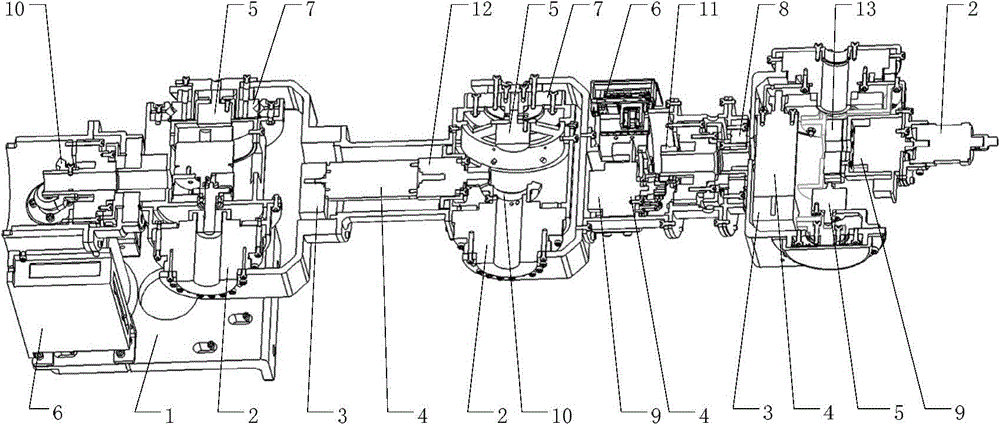

[0053] Further, the epicyclic joint I includes a servo motor I, a servo driver I, a reduction mechanism I, an incremental encoder I, a cross roller bearing I, a rotating bearing mechanism I and a fixed bearing mechanism I, wherein the servo The motor I is fixed on the fixed bearing mechanism I, one end of the servo motor I is connected with the incremental encoder I, and the other end of the servo motor I is connected with the reduction mechanism I, and the reduction mechanism I is connected by a pair of planetary reduction boxes The bevel gear is connected to the harmonic reducer to form; the cr...

Embodiment 2

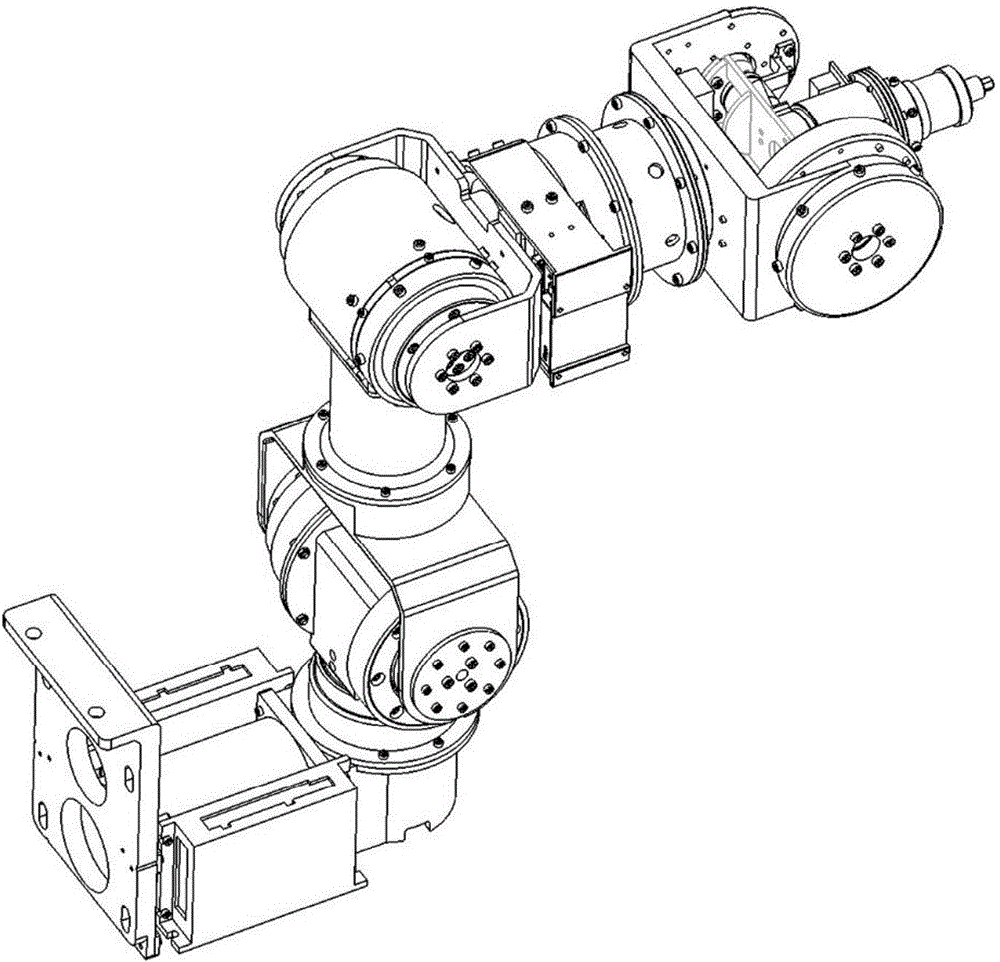

[0063] This embodiment provides a space series rotary joint teleoperated manipulator, including any one or more of the following configurations:

[0064] - the wrist joint part, which is mainly composed of the axes of the epicyclic joint I, pitch joint II and pitch joint III provided in embodiment 1 intersecting at one point;

[0065] - The arm joint part is mainly composed of the front epicyclic joint IV, the middle pitch-rotation joint V and the terminal epicyclic joint VI provided in Embodiment 1 in series;

[0066] Both the arm joint part and the wrist joint part have three degrees of freedom; the wrist joint part and / or the arm part are controlled through the EtherCAT bus.

[0067] Further, the arm joint part is located at the front end, including three series rotation joints: one epicyclic joint I, two pitch rotation joints II and III; the main design ideas and principles of the three series joints are the same, only in the structural design and space Layouts vary.

[...

Embodiment 3

[0127] This embodiment provides a combined space-series rotary joint-type teleoperation manipulator, including a plurality of interconnected space-series rotation-joint teleoperation manipulators provided in Embodiment 1 and / or Embodiment 2. In this embodiment Wherein, the connection relationship defined by the interconnection includes a direct connection relationship or an indirect connection relationship, for example, including the indirect connection relationship in which a plurality of the space series rotary joint type teleoperated manipulators are sequentially connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com