Three pin positioning structure positioning plate

A technology of positioning structure and positioning plate, applied in the direction of positioning device, clamping, support, etc., to achieve the effect of ensuring positioning accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

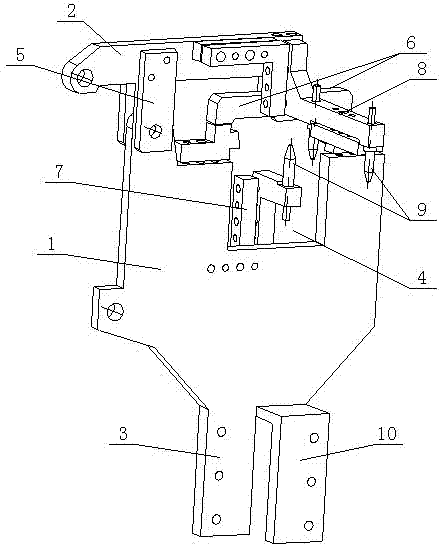

[0010] Such as figure 1 As shown, the positioning plate of the three-needle positioning structure described in the embodiment of the present invention includes an overturning beam 2 and a positioning plate 1, and the left side of the bottom of the positioning plate 1 is a straight connecting plate 3 integrally formed with the positioning plate 1. The right side of the bottom of the positioning plate 1 is provided with an L-shaped connecting plate 10, the L-shaped connecting plate 10 is integrally formed with the positioning plate 1, the top of the positioning plate 1 is provided with a notch 4, and the right side of the flip beam 2 The support plate 5 is hinged with the positioning plate 1, the overturn beam 2 is fixedly connected with the support plate 5, the left side of the overturn beam 2 is connected with the center of a door-shaped seat 6, and the door-shaped seat 6 is docked with the notch 4 of the positioning plate; the inside of the notch is provided with a first thim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com