Tower crane standard section processing device and processing method

A technology for tower cranes and processing devices, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of heavy main chord, heavy workload, main chord deviation, etc., to reduce labor intensity , Improve work efficiency and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

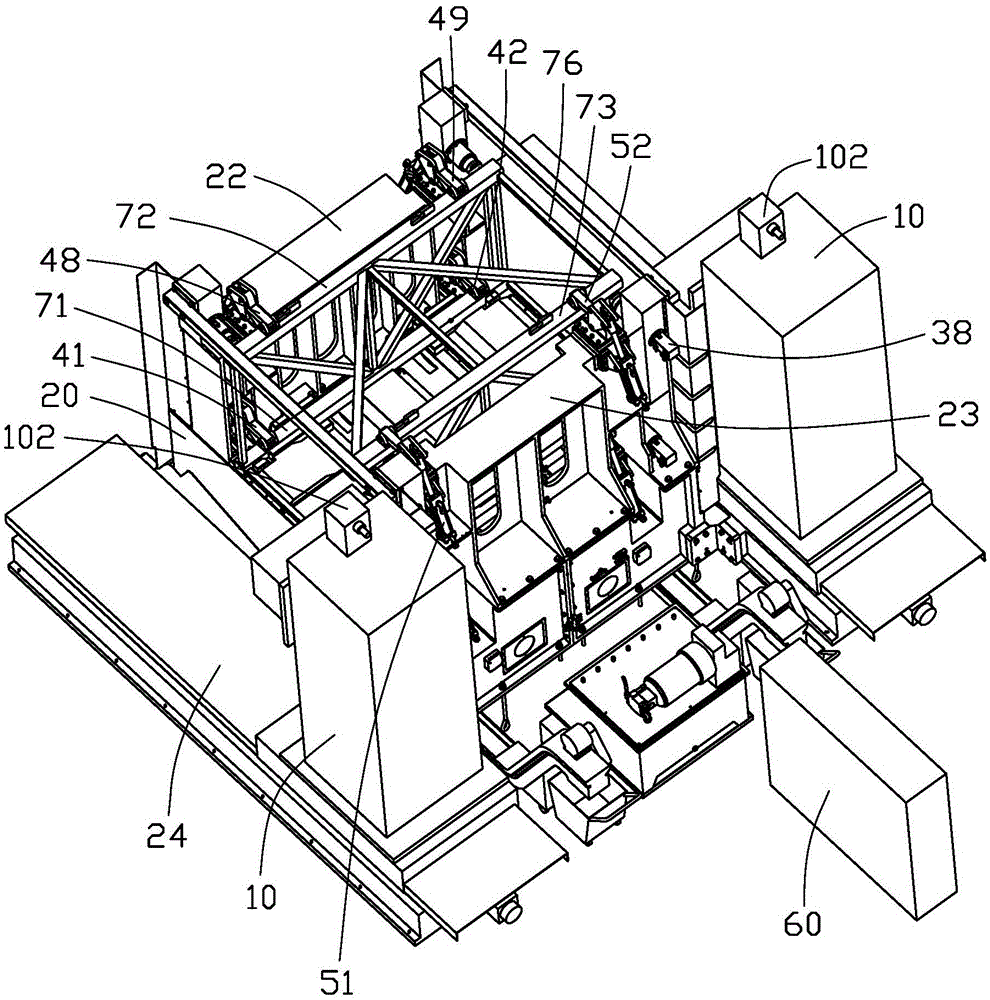

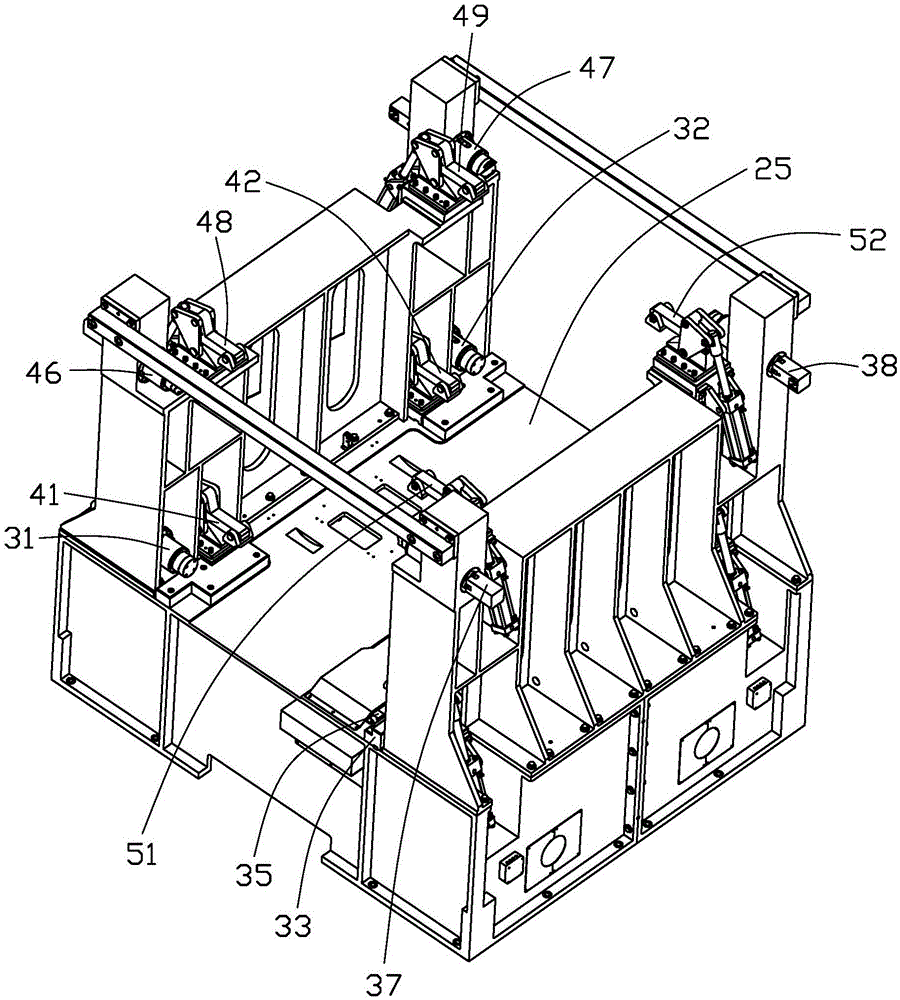

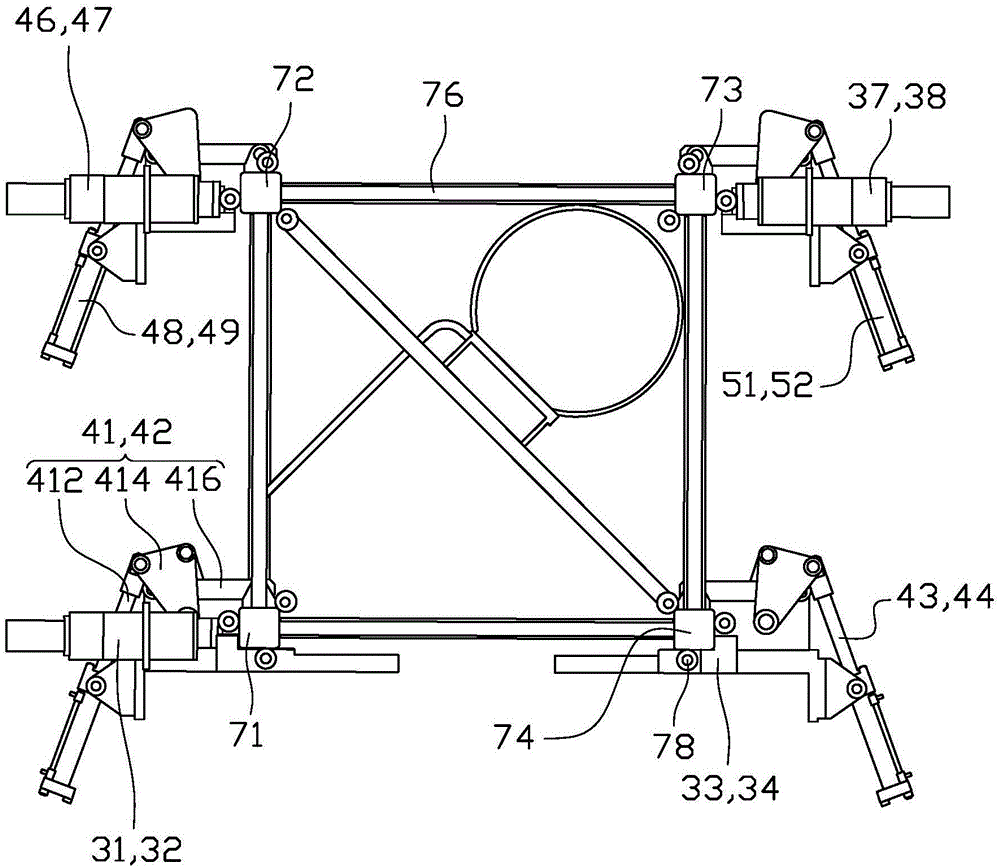

[0033] see Figure 1 to Figure 3 According to the present invention, the processing device for milling standard joints in tower cranes includes a special milling machine 10, a processing platform 20 and a positioning and clamping device. The standard section includes four main chords arranged in parallel and welded into a square frame shape, that is, the first main chord 71 at the lower left, the second main chord 72 at the upper left, and the third main chord at the upper right. Rod 73 and the fourth main chord 74 on the lower right; the first main chord 71 and the third main chord 73 are arranged diagonally, and the second main chord 72 and the fourth main chord 74 are arranged diagonally , the main chords are welded and connected by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com