Planting bed composite structure for high-density indoor planting

A combined structure and planting bed technology, applied in the field of planting bed combined structure for high-density indoor planting, can solve the problem that nutrient solution oil slick or impurities cannot be smoothly discharged and filtered, and the nutrient solution concentration cannot be evenly distributed to the roots of each plant, etc. problem, to achieve the effect of reducing residual nutrients, growth rate and size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

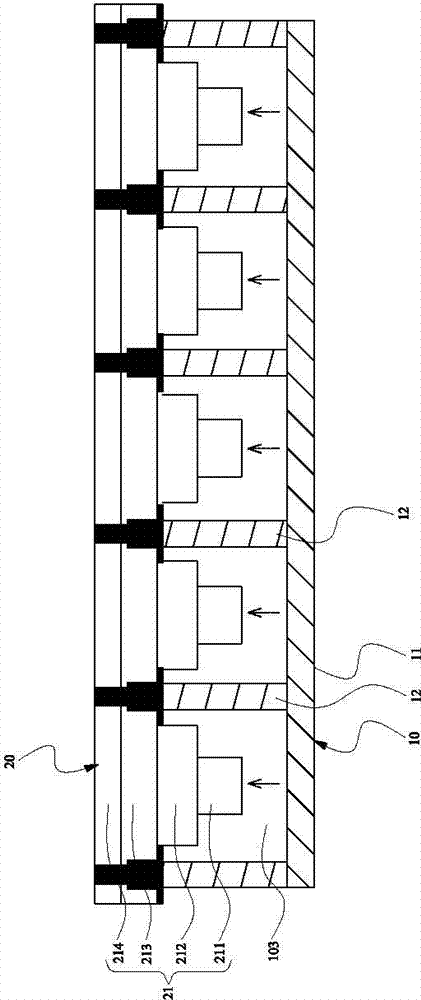

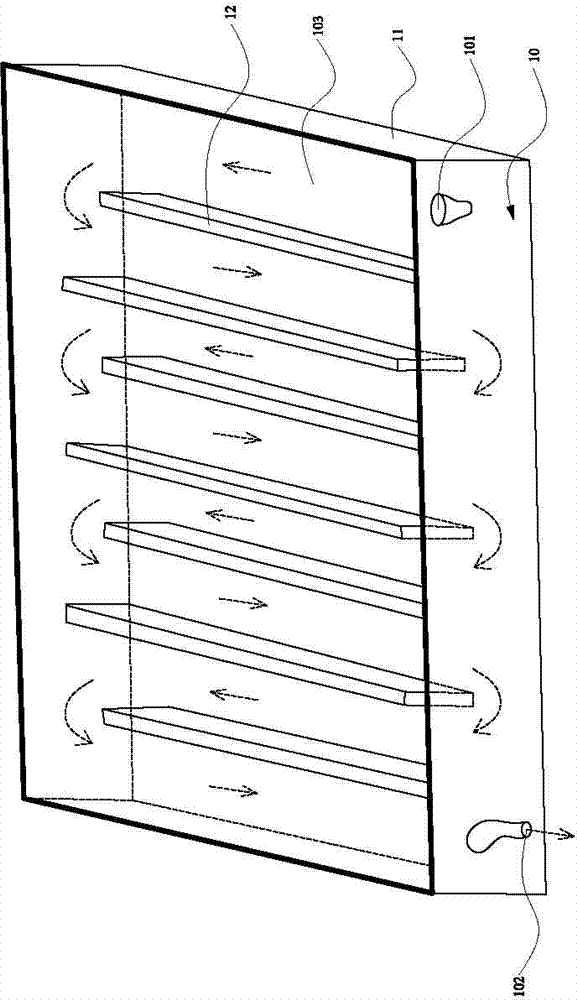

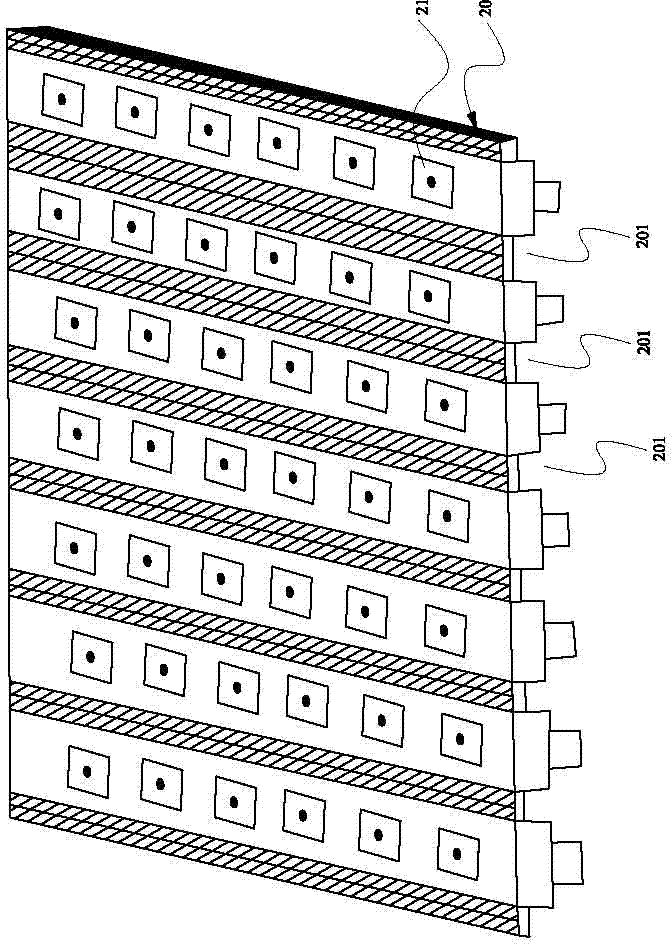

[0027] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the planting tank body 10 and the planting floating plate 20 .

[0028] Among them, such as figure 2 As shown, the planting tank body 10 is provided with an injection port 101 and an overflow port 102, and the planting tank body 10 is provided with a diversion groove 103. The diversion groove 103 has a circuitous S-shaped structure, and the diversion groove The input end of the groove 103 is connected to the injection port 101, the output end of the diversion groove 103 is connected to the overflow port 102, and the height of the injection port 101 relative to the bottom surface of the diversion groove 103 is greater than the height of the overflow port 102 relative to the bottom surface of the diversion groove 103 height, and the height of the overflow port 102 can be adjusted with the different crops to be planted. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com