System and method for additive manufacturing of an object

A technology for additive manufacturing and objects, applied in the field of systems and methods for additive manufacturing of objects, capable of solving problems such as inoperability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

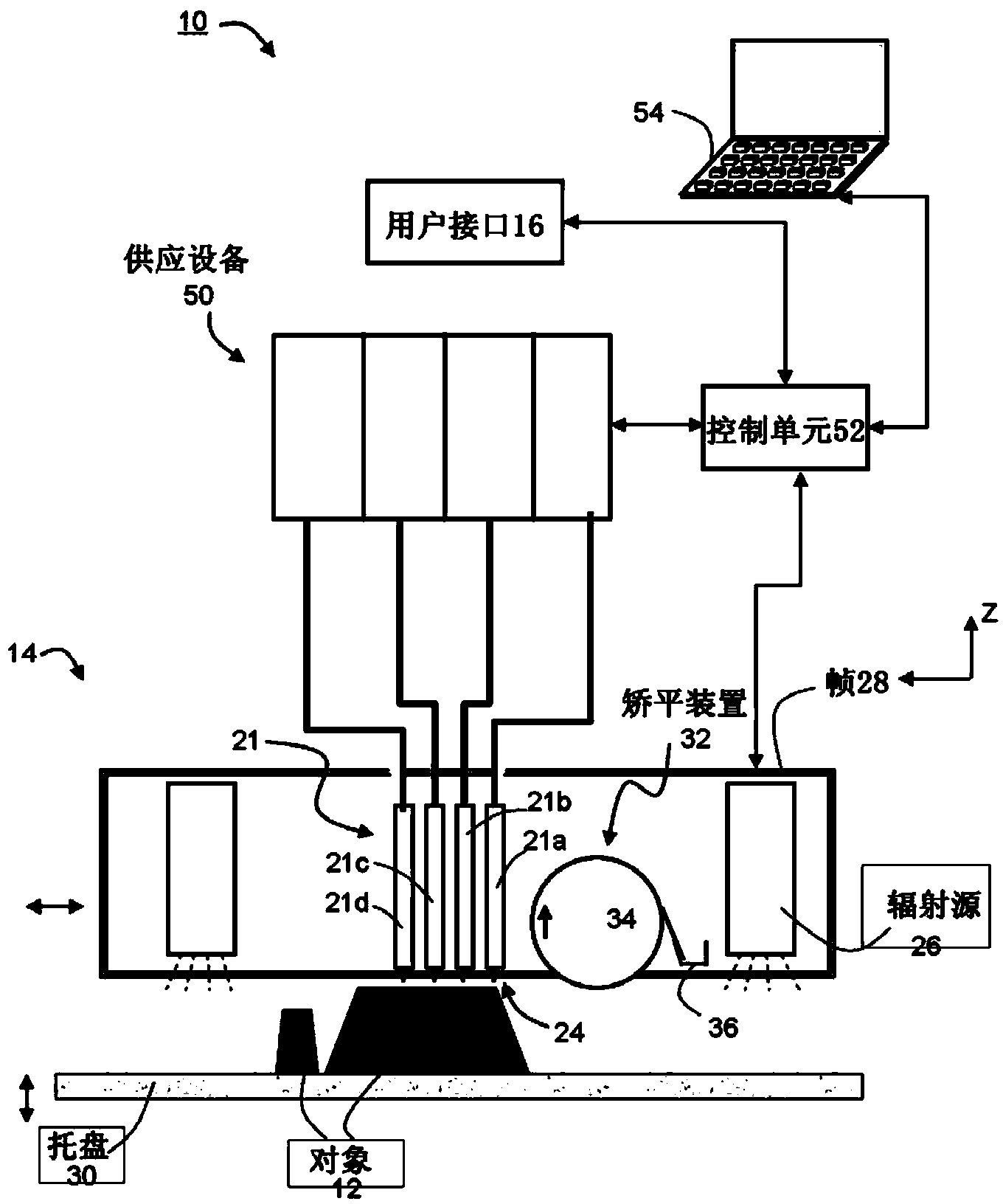

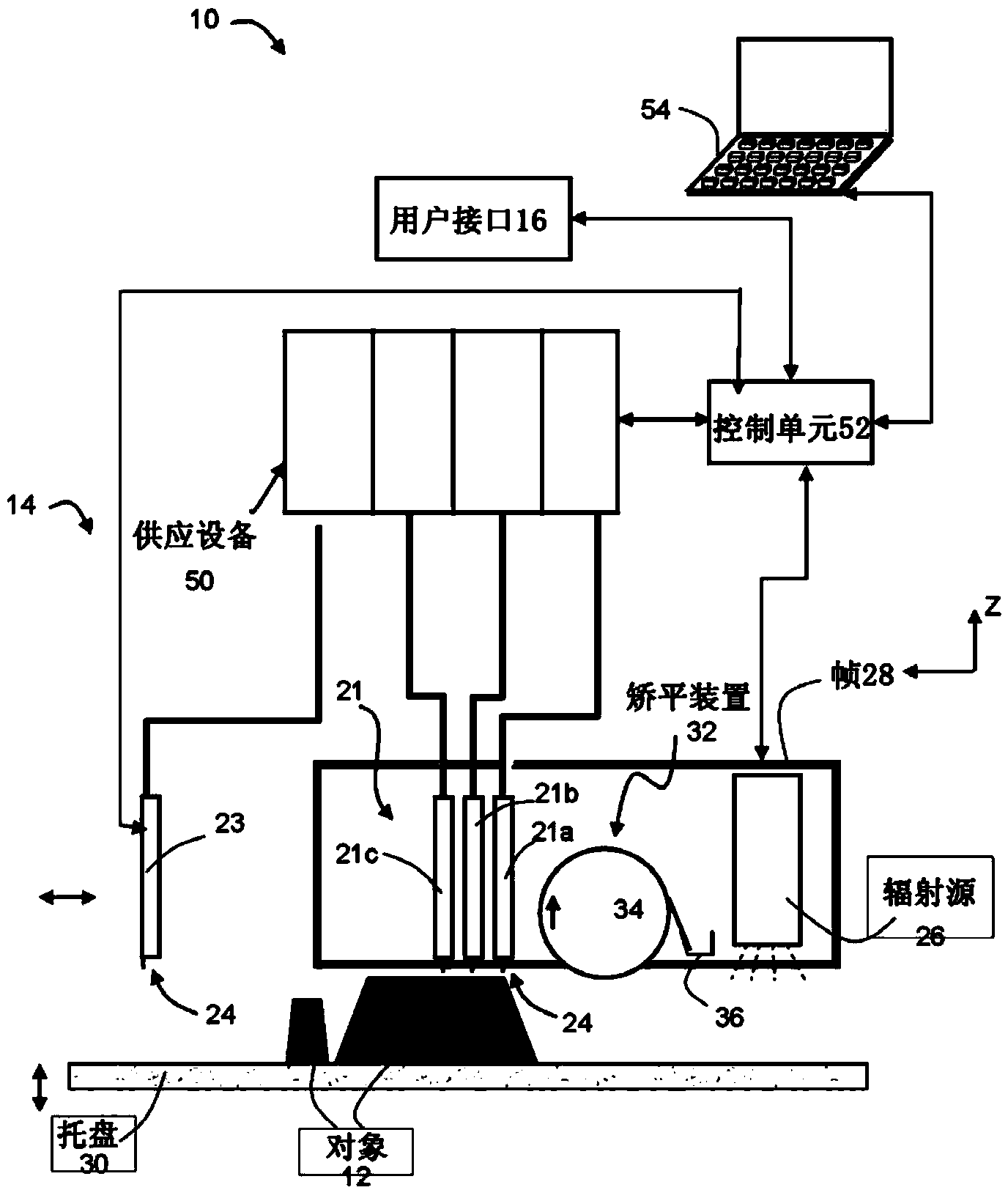

[0068] The present invention, in some embodiments thereof, relates to additive manufacturing (AM) of objects, and more particularly, but not exclusively, to a system and method for AM of objects utilizing a combination of materials and / or scan patterns.

[0069] Before explaining at least one embodiment of the present invention in detail, it should be understood that the present invention is not necessarily limited in application to the components and / or components and / or Details of the structure and arrangement of the method. The invention is capable of other embodiments or of being practiced or carried out in various ways.

[0070] The method and system of the embodiments of the present invention manufacture a three-dimensional object in a step-by-step manner by forming multiple layers in a configuration pattern corresponding to the shape of the object.

[0071] As used herein, the term "object" refers to an entire object or a portion thereof.

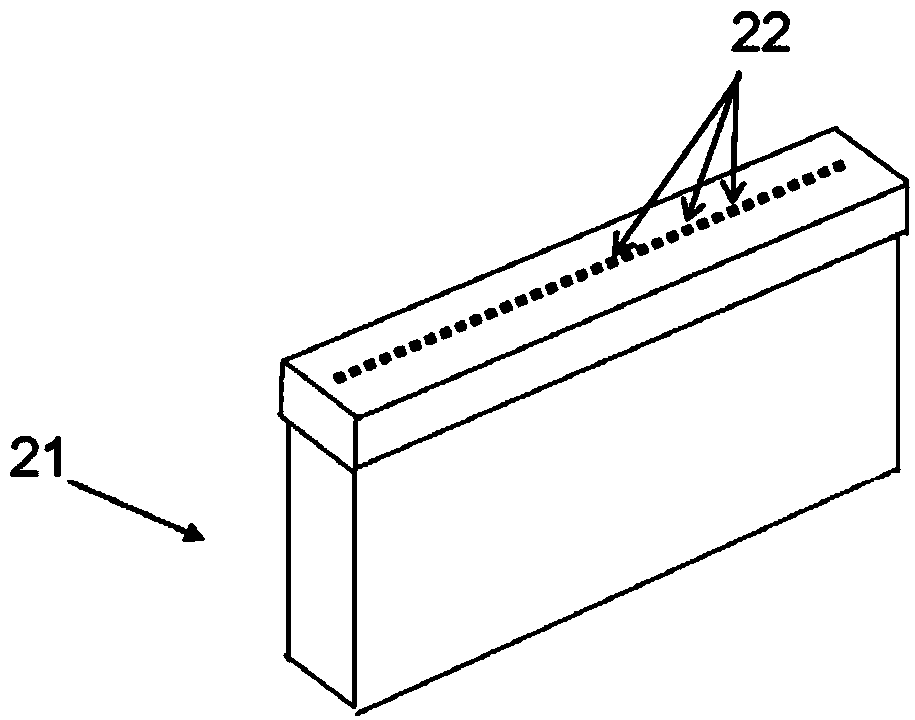

[0072] Each layer is formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com