Mobile phone camera integrated assembling equipment

A mobile phone camera and assembly equipment technology, applied to the structure of telephones, etc., can solve the problems of poor assembly quality and low production efficiency, and achieve the effects of reducing purchase costs, improving quality, and uniform light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

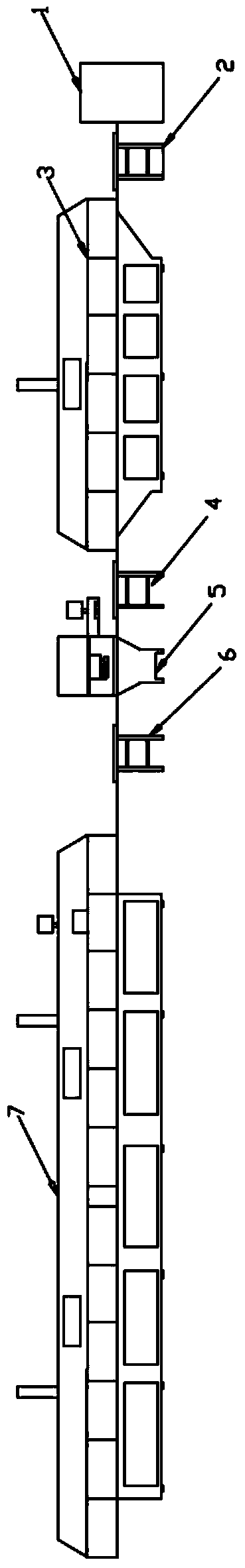

[0029] Such as figure 1 As shown, an integrated mobile phone camera assembly equipment includes an automatic cleaning machine 3, a glue dispensing and mounting machine 5, and an infrared tunnel drying oven 7. The automatic cleaning machine 3 is connected to the output end of the chip reflow soldering 1 through a connecting machine 2 , the output end of the automatic cleaning machine 3 is connected to the dispensing and mounting machine 5 through the connecting machine 4, and the fixture pressing workbench 6 is connected between the output end of the dispensing and mounting machine 5 and the input end of the infrared tunnel drying furnace 7 , the jig pressing workbench 6 covers the general jig to the product output by the dispensing and placement machine 5 .

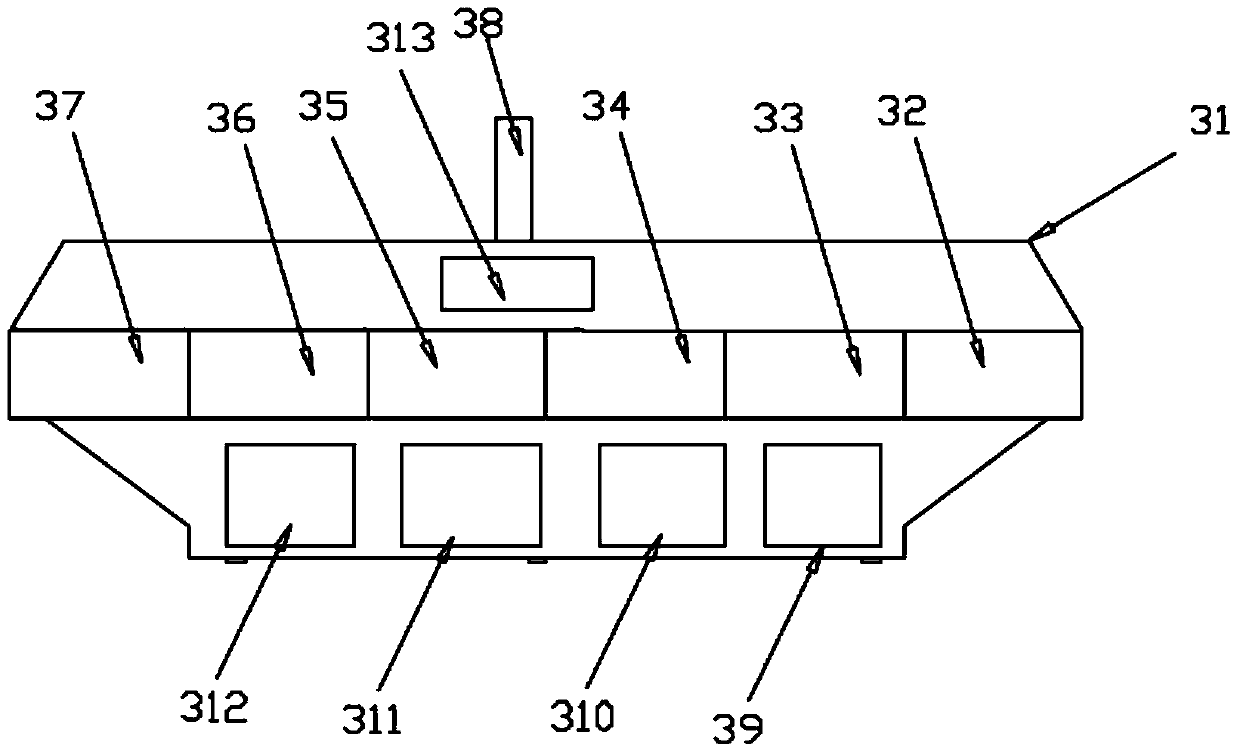

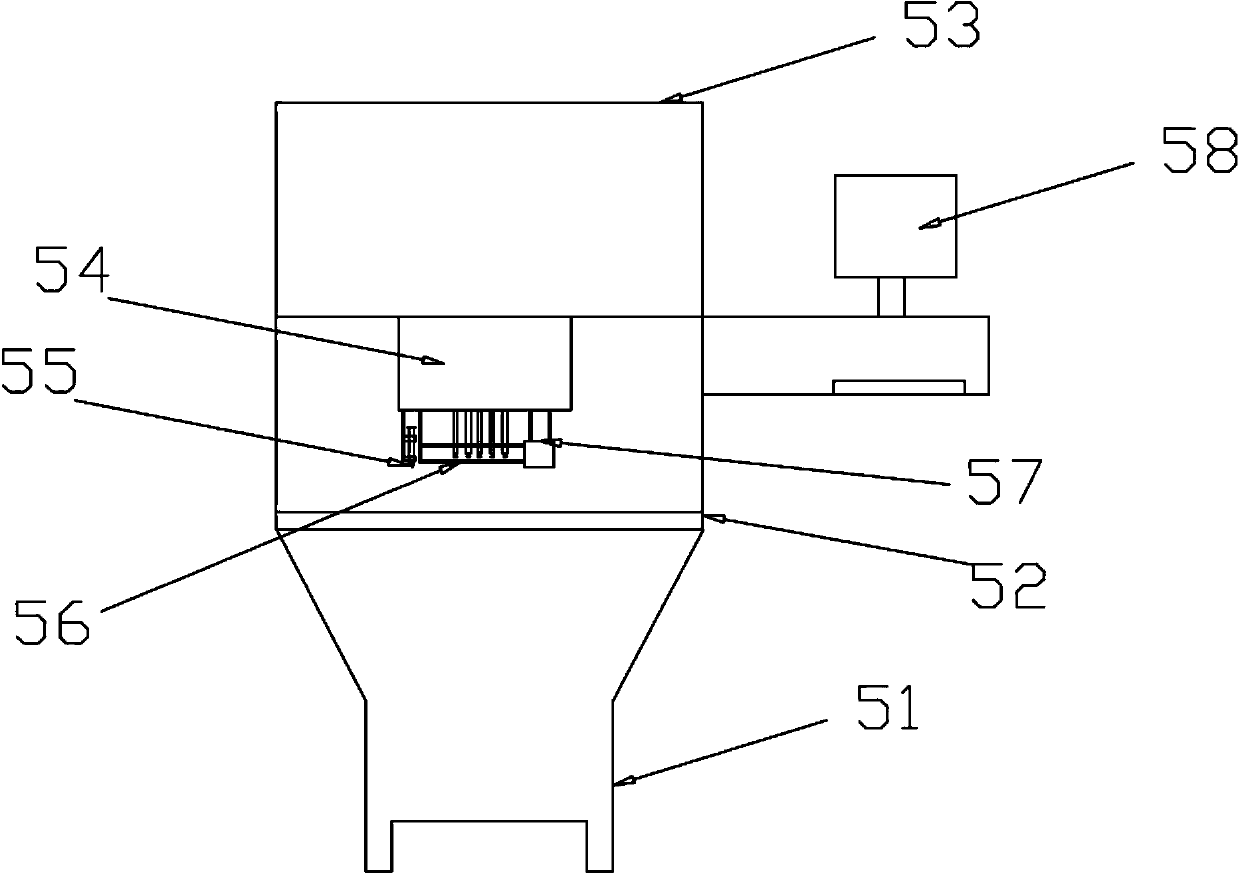

[0030] Such ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap