Protection strengthening type wing-shaped fixture

A reinforced fixture technology, which is applied in the field of wing fixtures, can solve the problems of broken pull plates on both sides, insulator strings or wires falling off, hindering the assembly and operation of live working tools, etc., and achieve the effect of increasing the stroke margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

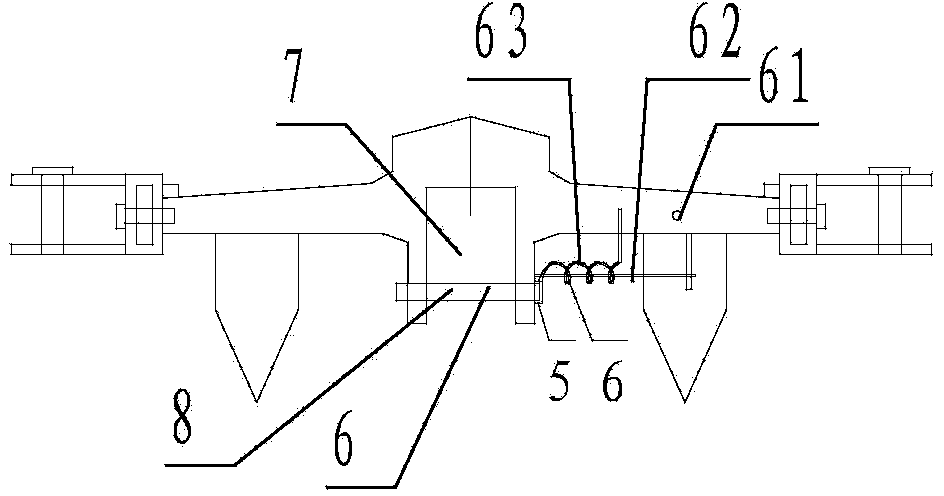

Embodiment 1

[0024] A protection-reinforced wing-shaped fixture, including a front clamp 1, a rear clamp 2, insulating pull plates 3 on both sides, and an insulating protection rope 4, and two sides of the front clamp and the rear clamp are provided with parallel to the insulation pull The protective insulation protection rope of the board and the tightening screw rod 5, one end of the insulating protection rope is arranged on the front card, and the other end is connected with the tightening screw rod, and the tightening screw rod is connected on the rear card, and the wire of the tightening screw rod The rod length is greater than the screw length of the tight-wire screw used to fix the insulating stay plate. Also be provided with card slot door sealing device 6 on the front clamping fixture, described card slot door sealing device 6 includes bayonet pin 61 frame and spring guide rod 62, described bayonet pin frame and spring guide rod are arranged on for card slot. Enter one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com