Intelligent integration high-voltage alternating current contactor

A high-voltage AC and contactor technology, applied in the field of electric power, can solve problems such as unreasonable design of mechanical operating mechanisms and electrical control circuits, unsatisfactory mechanical and electrical characteristics of high-voltage contactors, human-machine contact, and weak online functions. Facilitate human-machine contact, ideal electrical characteristics, and avoid the effect of unstable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

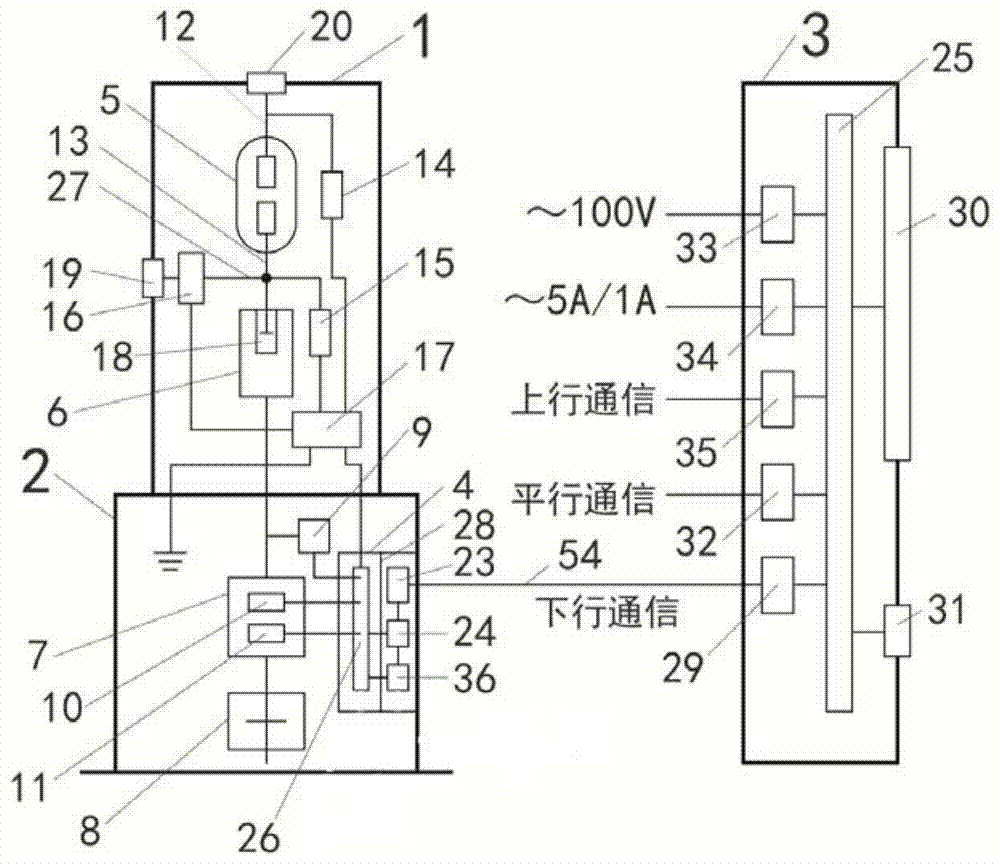

[0036] An intelligent integrated high-voltage AC contactor, such as figure 1 As shown, it includes a pole 1, a body 2, a body controller 4 and a front controller 3.

[0037] One, Pole 1:

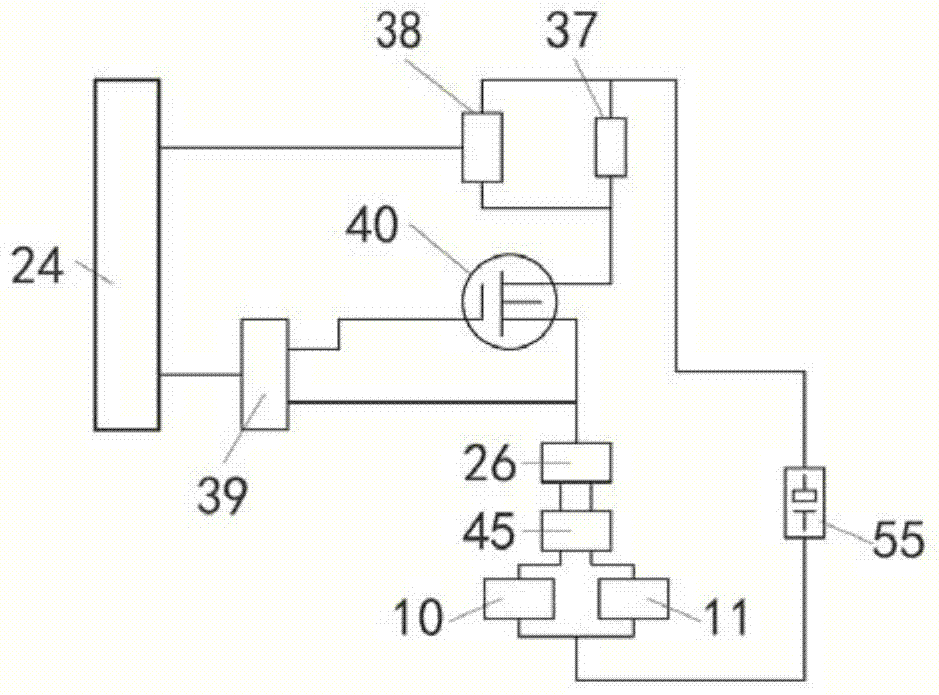

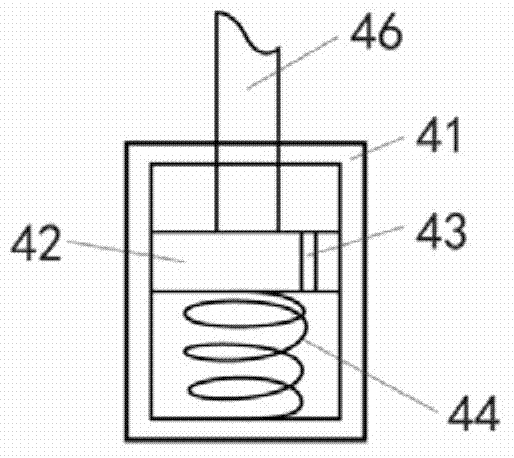

[0038] Such as figure 1 As shown, the pole 1 is provided with a vacuum switch tube 5 , an insulator 6 and an energy dissipator 18 . , The energy consumer cylinder 41 of the energy consumer 18 is embedded in the insulator 6 . The pole 1 also includes a first impedance member 14, a second impedance member 15, a current transformer 16, a connector 17, a static contact lead-out terminal 20 of the vacuum switch tube 5 and a moving contact of the vacuum switch tube 5 Lead out connection terminal 19; one end of the first impedance element 14 is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com