Dressing safety detection method for worker on working site of electric power facility

A technology for job sites and power facilities, which is applied in the field of detection and can solve problems such as high dangers and potential safety hazards of power system facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] A method for detecting the clothing safety of personnel at a power facility operation site, comprising the following steps:

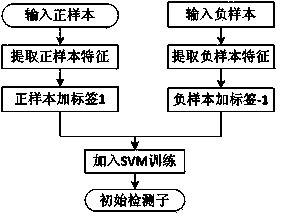

[0048] 1) Positive and negative sample preparation steps;

[0049] The positive sample is a picture containing various forms and clothing of the personnel on the job site, and the pixel size of the picture is uniform. The negative sample is any picture except the positive sample, and the size is the same as the positive sample; Negative sample images are mainly background images in job site scenes, such as roads, lawns, buildings, power facilities, etc.

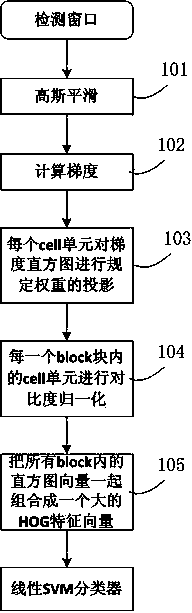

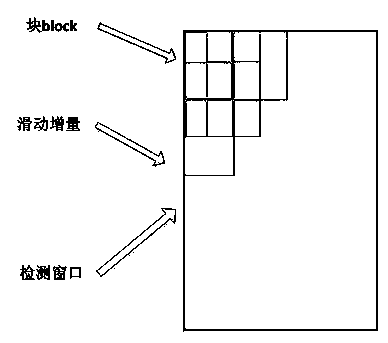

[0050] 2) HOG feature extraction steps, such as Figure 1-3 As shown, it specifically includes the following sub-steps:

[0051] Step 101, Gaussian smoothing is performed on all input positive and negative sample images to remove noise;

[0052] Step 102: Use the [-1,0,1] gradient operator to perform convolution to obtain the gradient component in the x direction, and then use the [1,0,-1]T g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com