Defrosting method of fresh-air machine system

A technology for fresh air fans and fresh air fans, applied in heating and ventilation control systems, heating and ventilation safety systems, air conditioning systems, etc., can solve the problem of reducing indoor temperature, low indoor fresh air temperature, and inability to solve the problem of plate heat exchanger frosting, etc. problem, to prevent the indoor temperature from decreasing and to avoid the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

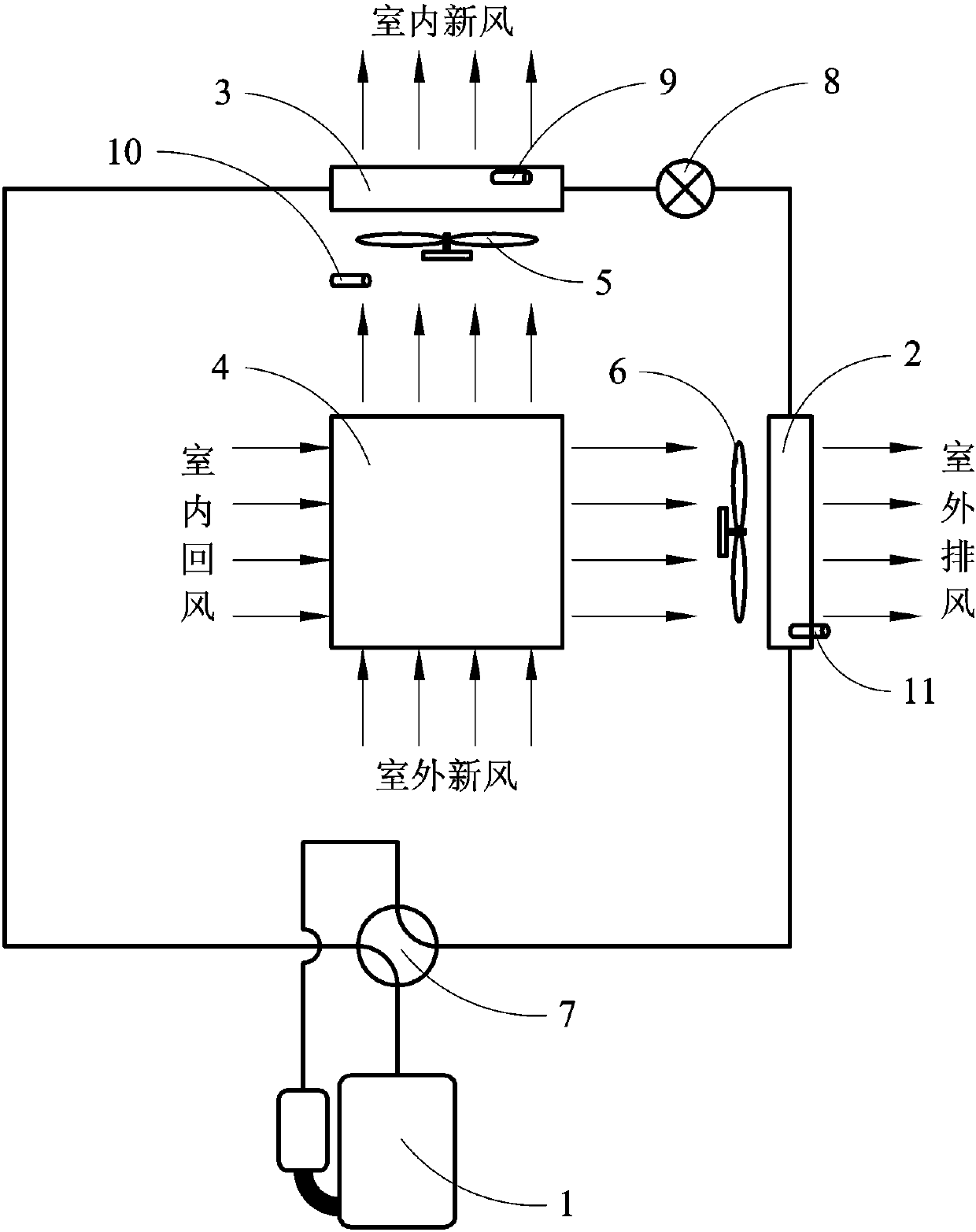

[0023] Embodiment 1: A defrosting method for a fresh air fan system, which can be applied to the attached figure 1 In the fresh air system shown.

[0024] The fresh air system includes a compressor 1 , an exhaust heat exchanger 2 , a fresh air heat exchanger 3 , a main heat exchanger 4 , a fresh air blower 5 and an exhaust blower 6 . The fresh air fan 5 is arranged relative to the fresh air heat exchanger 3 , and the exhaust fan 6 is arranged relative to the exhaust heat exchanger 2 . The compressor 1 , the exhaust air heat exchanger 2 and the fresh air heat exchanger 3 are connected to form a circuit through pipelines, and a four-way valve 7 and a throttling device 8 are also arranged on the circuit. The main heat exchanger 4 can be a plate heat exchanger. Multiple temperature sensors can also be set in the fresh air system, such as the intermediate temperature sensor 9 for detecting the intermediate temperature of the fresh air heat exchanger 3, the suction temperature sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com